address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

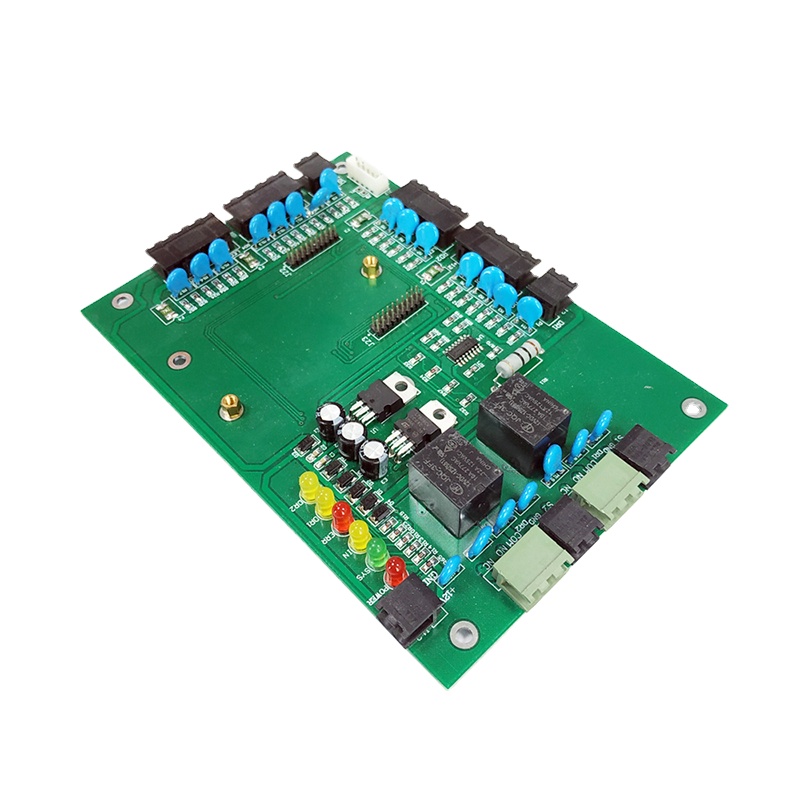

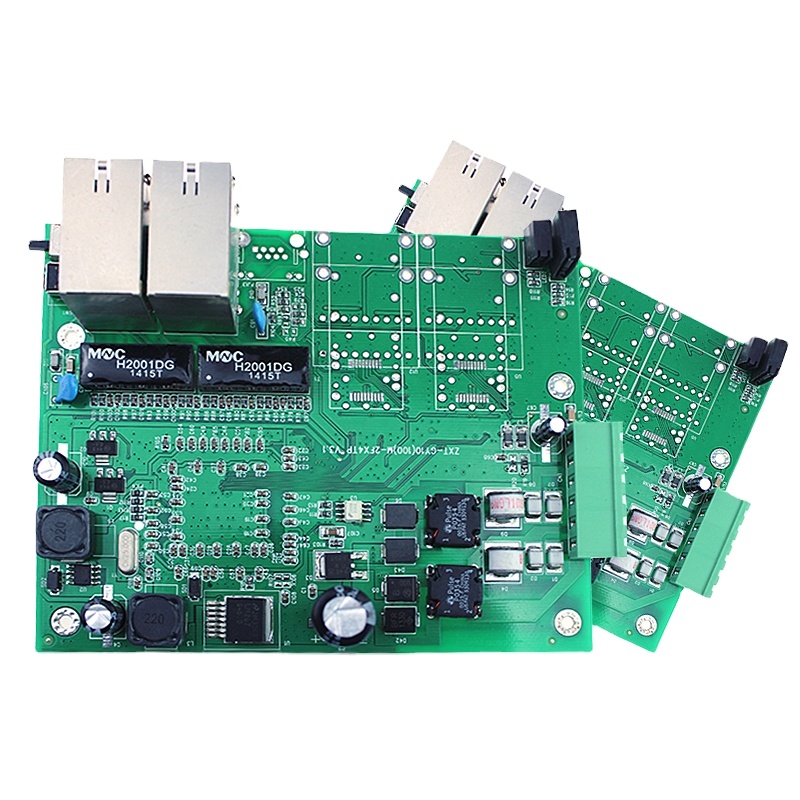

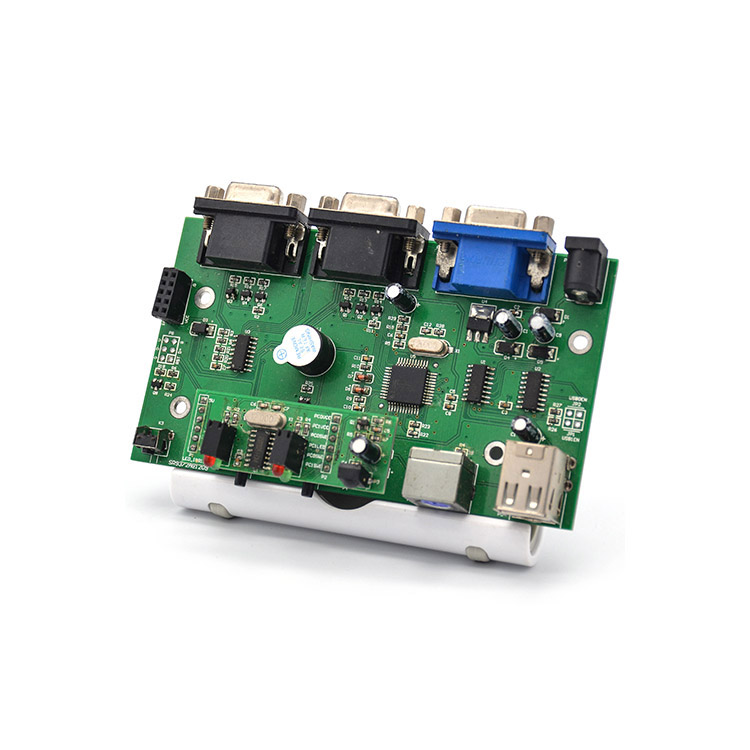

Intelligent humidifier PCBA design and development scheme

The humidifier can humidify the designated room, and can also be connected to the central air conditioning system to humidify the whole building. Compared with the traditional humidifier, the intelligent humidifier can automatically control the working state of the ultrasonic humidifier, which can realize intelligent regulation and humanized operation. The intelligent mobile humidifier with quantitative setting, the humidifier PCBA designed this time is based on a simple and simple robot as a platform, which gets rid of the constraints of the traditional fixed humidifier. The indoor humidity is kept uniform, which is in line with the lifestyle of modern people.

Smart humidifier PCBA working principle:

After monitoring the corresponding humidity range, it will automatically start or stop working; it can realize free movement in the entire room to ensure uniform driving; when the humidifier is about to dry out, start the sound and light alarm; according to the monitored humidity value, automatically Adjust the spray size; display the indoor humidity in real time; the best humidity value can be customized by the user. In order to achieve these requirements, the humidifier is mainly divided into 7 modules for coordination work: the central control module with the single-chip microcomputer as the core, the sensor module with the DHT11 as the core, the intelligent drive module with the L298N as the core, and the LED LCD screen as the core. Display module, sound and light alarm module, power supply module and peripheral independent keyboard, the specific structure is shown in Figure 1. The sensor module will monitor the indoor humidity in real time, display it on the LED display, and transmit the data to the central controller. Once the indoor humidity reaches the optimal relative humidity set by the user, the central controller will send commands to make the humidifier and The bottom trolley stops working; when the indoor humidity drops below the set minimum humidity, the humidifier and the trolley will work again. During this period, the humidifier will automatically select the appropriate spray size according to the indoor humidity to ensure indoor comfort; When the water level in the humidifier drops to the preset minimum water level, the humidifier will stop humidifying, and the sound and light alarm module will issue an alarm to remind the user to add water in time to prevent dry burning.

Smart humidifier PCBA hardware design:

(1) Central control module: There are two central control modules based on single-chip microcomputers, one is responsible for controlling the humidity monitoring of the humidifier and the working state of the humidifier, and the other is for controlling the related functions of the simple car at the bottom, such as obstacle avoidance, turning, Start, stop, etc., the two microcontrollers are connected and controlled by a relay. The microcontroller on the humidifier is the main one, and the microcontroller on the simple car is controlled to send commands. The selected single-chip microcomputer is a new generation of 51 single-chip microcomputer with high speed, low power consumption and super anti-interference. The working voltage is 5.5~3.5V, and there are 8 high-speed 10-bit A/D conversions inside, which can directly transfer the data of the temperature and humidity sensor to the single-chip microcomputer. Internal analog-to-digital conversion, eliminating the need for an external A/D conversion module.

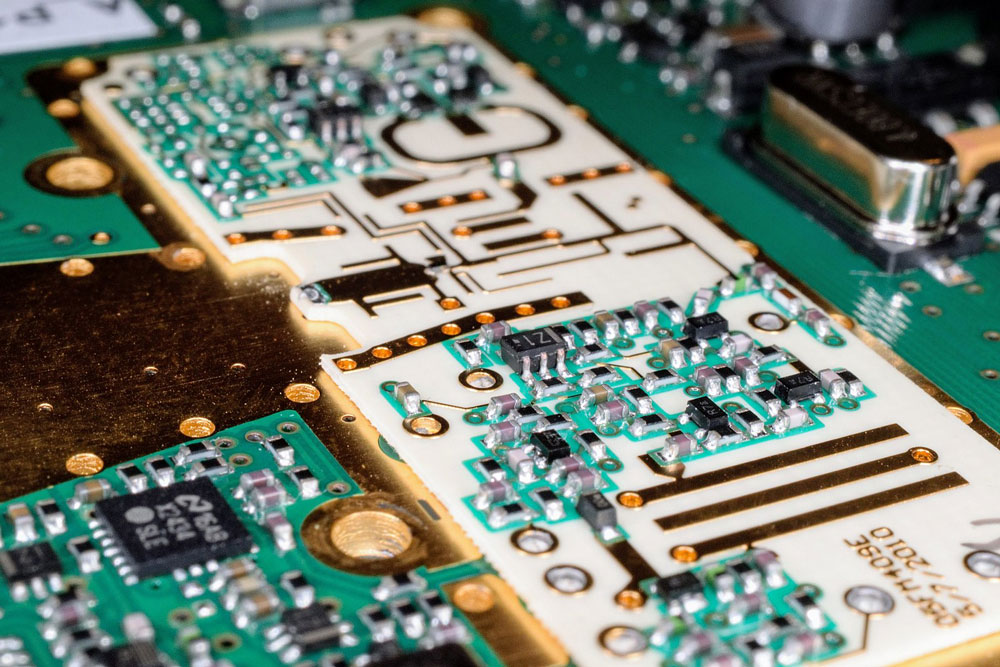

(2) Intelligent drive module: Since the stepper motor has higher precision than ordinary motors and is easy to control, the humidifier designed in this paper uses a stepper motor and an L298N motor driver chip. L298N is a monolithic integrated circuit, high voltage, high current, four-channel drive, which can directly control the motor without isolation circuit. By changing the level of the control terminal of the chip through the I/O input of the single-chip microcomputer, the operation of forward, reverse and stop of the motor can be performed, which is very convenient and can also meet the high current requirements of the DC gear motor. When debugging, follow the chip manual and use the program. The corresponding action can be realized by entering the corresponding code value. The circuit principle of the drive module is shown in Figure 2.

(3) Power supply module: The power supply used in this design includes 5V microcontroller power supply, 5V motor driver chip power supply and 7.2V motor power supply, but only two 3.6V lithium batteries are used for power supply. Therefore, in the power supply module It is also necessary to add a 7805 voltage drop circuit to reduce the voltage and maintain the normal operation of the circuit.

(4) When the water level sensor detects that the water level in the humidifier drops to the set minimum water level, the central control module sends a command, that is, a low level is issued, and the buzzer emits an alarm sound of "Di Di".

(5) Sensor module: The sensor module is based on DHT11. DHT11 is a temperature and humidity sensor that has stored a calibrated digital signal, including a humidity sensing element and a temperature measuring element, and these two elements are internally connected with a high-performance 8 The single-chip microcomputer is connected to complete the acquisition of temperature and humidity.

(6) LED display module: In this design, a liquid crystal display is used as the output status display, which has the advantages of good stability and not easy to flicker. After the central control module receives the humidity information sent by the temperature and humidity sensor, it uses the existing 8-bit high-speed A/D conversion module to convert the information into digital signals inside the single-chip microcomputer, and then input the information to the liquid crystal display that works with the common cathode.

Smart humidifier PCBA design parameters:

| Mechanical rigidity | rigid |

| Layers | Double Sided |

| Substrate | Copper |

| Insulation material | organic resin |

| Insulation thickness | conventional board |

| Flame retardant properties | VO board |

| Processing technology | electrolytic foil |

| Reinforcing material | glass fiber cloth |

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: