address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

KFPCBA

Welcome to visit, PCB design or manufacturing assembly one-stop EMS needs, please send us an email to help you, thank you

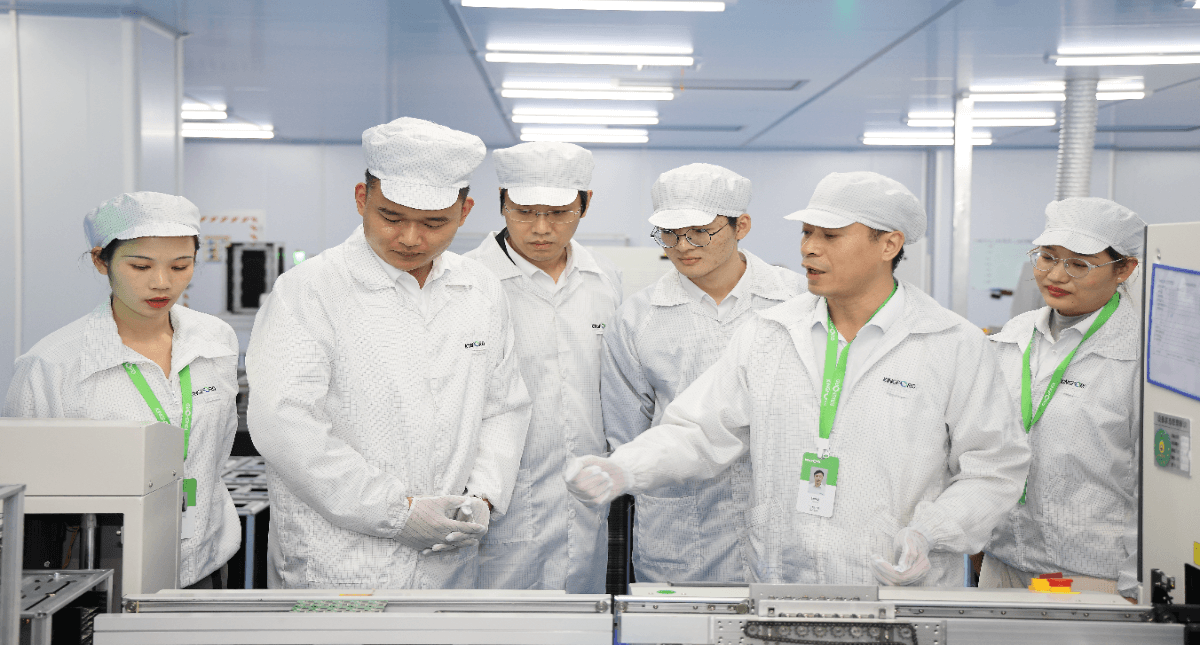

We offer a comprehensive PCB design and manufacturing assembly services that encompasses everything from initial design to final assembly. Our state-of-the-art facilities and experienced team of engineers enable us to provide efficient and cost-effective solutions to meet your electronic manufacturing needs.

Our PCB design service utilizes the latest software and design tools to create customized solutions for your unique application. Our team of experts will work closely with you to ensure that your design meets all of your specifications, while optimizing for manufacturability and cost-effectiveness.

In addition to design, we also offer PCB manufacturing services. With our in-house production capabilities and partnerships with trusted suppliers, we are able to offer a range of options to meet your production needs, from small-scale prototyping to high-volume production runs.

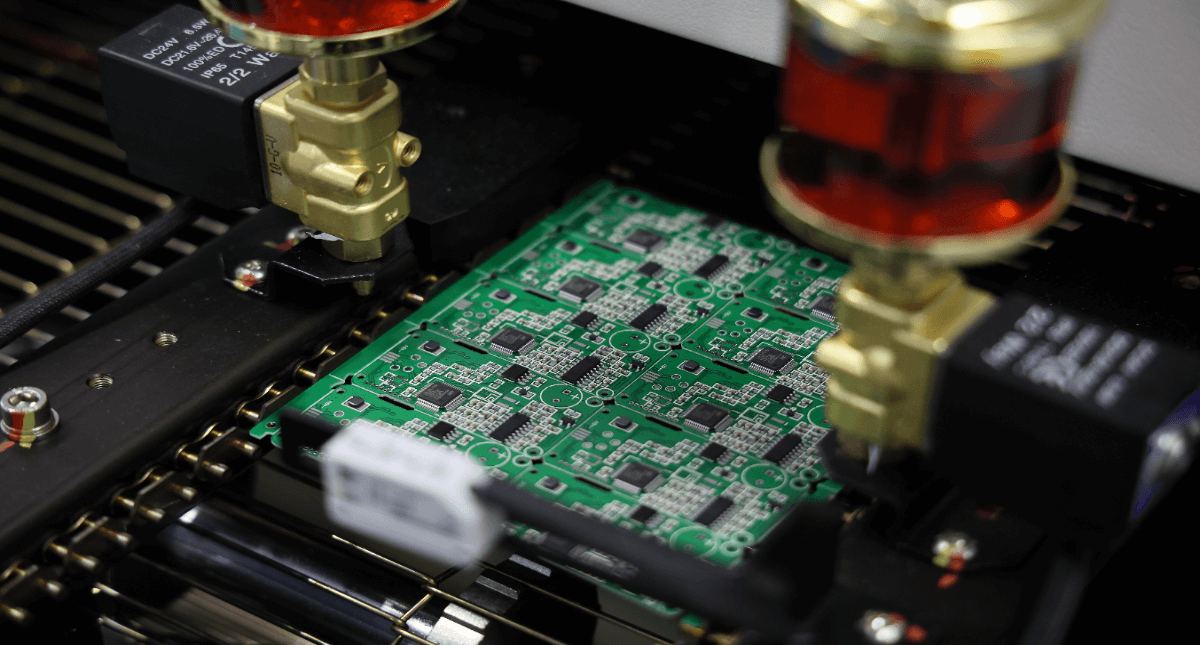

To further streamline the production process, we also offer surface-mount technology (SMT) and through-hole technology (DIP) assembly services. Our experienced technicians use advanced equipment to ensure precise and efficient assembly, while maintaining the highest quality standards.

Our one-stop approach to electronic manufacturing allows us to offer faster turnaround times, lower costs, and more consistent quality compared to traditional multi-vendor solutions. Whether you are looking for PCB design, manufacturing, or assembly services, we are here to provide a seamless and hassle-free experience.

We can help you:

Circuit schematic design

Component selection

Gerber File Creation

Rapid Prototype PCB Production Test

PCBA board assembly test

Electronic product shell assembly finished product testing

↓ Please email us to tell us the problems you encounter, so that we can help you, thank you

A reliable PCBA manufacturer. KFPCBA complies with ISO 9001:2015, IATF 16949, ISO 13485:2016, REACH, RoHS and UL certification. Here, you can click to view our PCB and SMT factory certificates located in Shenzhen and Huizhou, Guangdong, China.

We provide SMT placement, DIP plug-in, assembly and testing services. We have a 100,000-level dust-free SMT workshop of 4,000 square meters and a DIP dust-free processing workshop of 800 square meters. The daily SMT placement capacity can reach 19 million points, and the daily DIP plug-in can reach 10 Wan, KFPCBA carries out strict quality control on each process of PCB assembly, and has passed ISO9001, ISO13485, ISO14001, IATF 16949, UL and other authoritative certifications at home and abroad.

| Capability | Standard |

| Lead Time | 1-5 Days, As per the scheduled period |

| Parts procurement | Full Turnkey, Partial Turnkey, and Knitted |

| Assembly Types | Surface Mount (SMT), Thru-hole, Mixed Technology, Single and double-sided SMT/PTH. |

| Stencils | Laser cut stainless steel and Nano-coating |

| Components | Passive components smallest size 0201, Fine pitch components smallest size 8 Mils pitch |

| Component packaging | Reels, Cut Tape, Tube, and lose parts |

| Inspection | X-ray analysis, AOI, and Microscope to 20X |

| Solder Type | Leaded and Lead-free/ RoHS compliant |

| Assembly Surface mount connectors | Yes |

| Wave Soldering | Yes |

| PCB Finish | SMOB/HASL, Electrolytic gold, Electroless gold, Electroless silver, Immersion gold, Immersion gold, Immersion tin, and OSP. |

| Panelized PCB | Tab routed, Breakaway tabs, V-scored and Routed + V scored |

| Rework | BGA removal and replacement station, SMT IR rework station, and Thru-hole reworks station. |

| Design file format | Gerber RS-27, 274D, Eagle and Auto CAD's DXF, DWG BOM, and Pick and place a file |

Shenzhen factory is dedicated to our standard service equipped with 7 YAMAHA SMT lines, X-ray, and AOI, Spanning over 3000 square meters, with 170+ employees providing a quality assembly service at very reasonable prices.

Provide all kinds of PCB prototype assembly service you, including wiring harness assembly, injection and conformal coating.

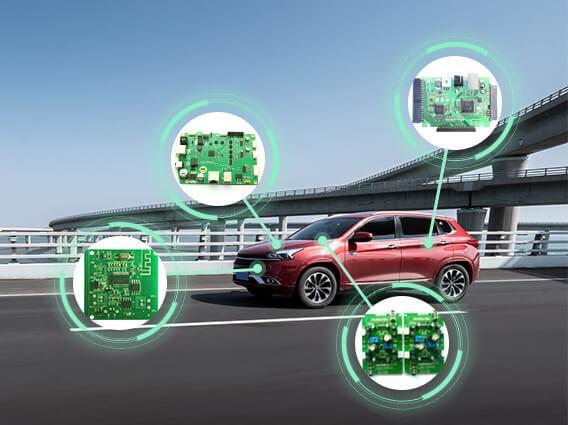

We provide customers with PCB assembly in various industries, from medical and health, automotive electronics, industrial control, smart home, artificial intelligence, Internet of Things and other industries PCB assembly services

We can assemble the following types of single-sided and double-sided SMT printed circuit boards: Ball Grid Array (BGA), Ultra Fine Ball Grid Array (uBGA), Quad ...More...

Yes, we are fully capable of handling any type of custom SMT prototyping board requirements for you.More...

SMT PCBs have a wide range of advantages, the most important being that they are suitable for small size and light weight printed circuit boards.More...

SMT assembly involves the following: application of solder paste, placement of components, and soldering of circuit boards using a reflow process. More...

Surface Mount Technology (SMT) is a method of mounting electronic components directly onto the surface of a printed circuit board.More...

Our quality management system passed IATE 16949:2016 is to ensure efficient printed circuit boards that meet customer requirements. And through ISO9001 and other system certification, become a member of IPC. All our products meet certification standards. More importantly, we have always been committed to providing high-quality one-stop PCBA manufacturing capabilities and providing one-stop ODM/OEM electronic product complete machine manufacturing services for our customers!