address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

OUR DFMA service capabilities

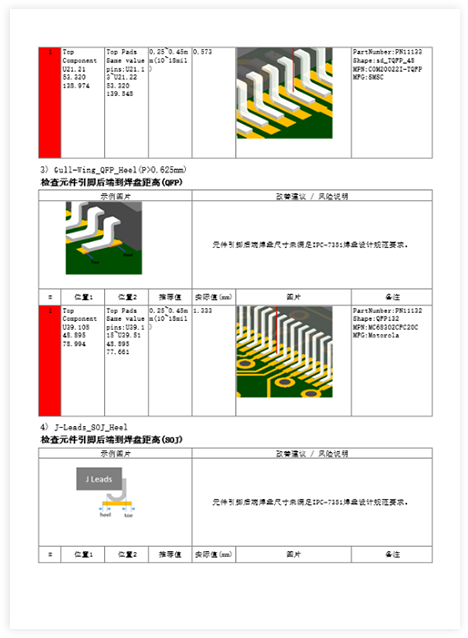

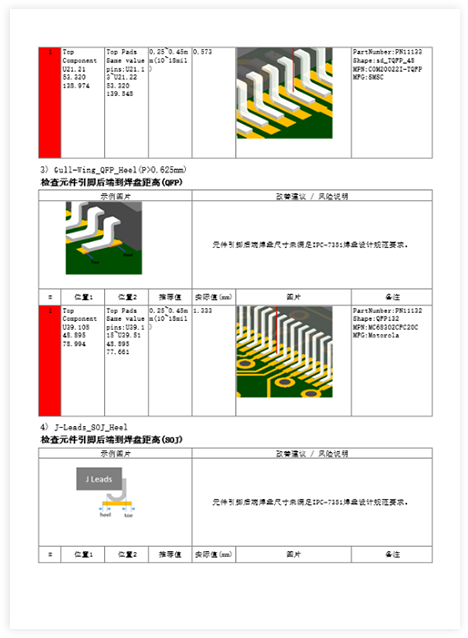

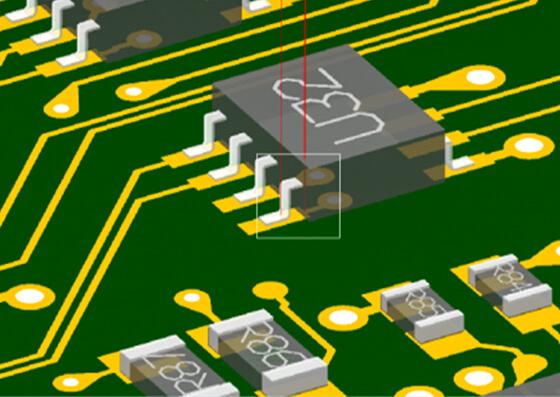

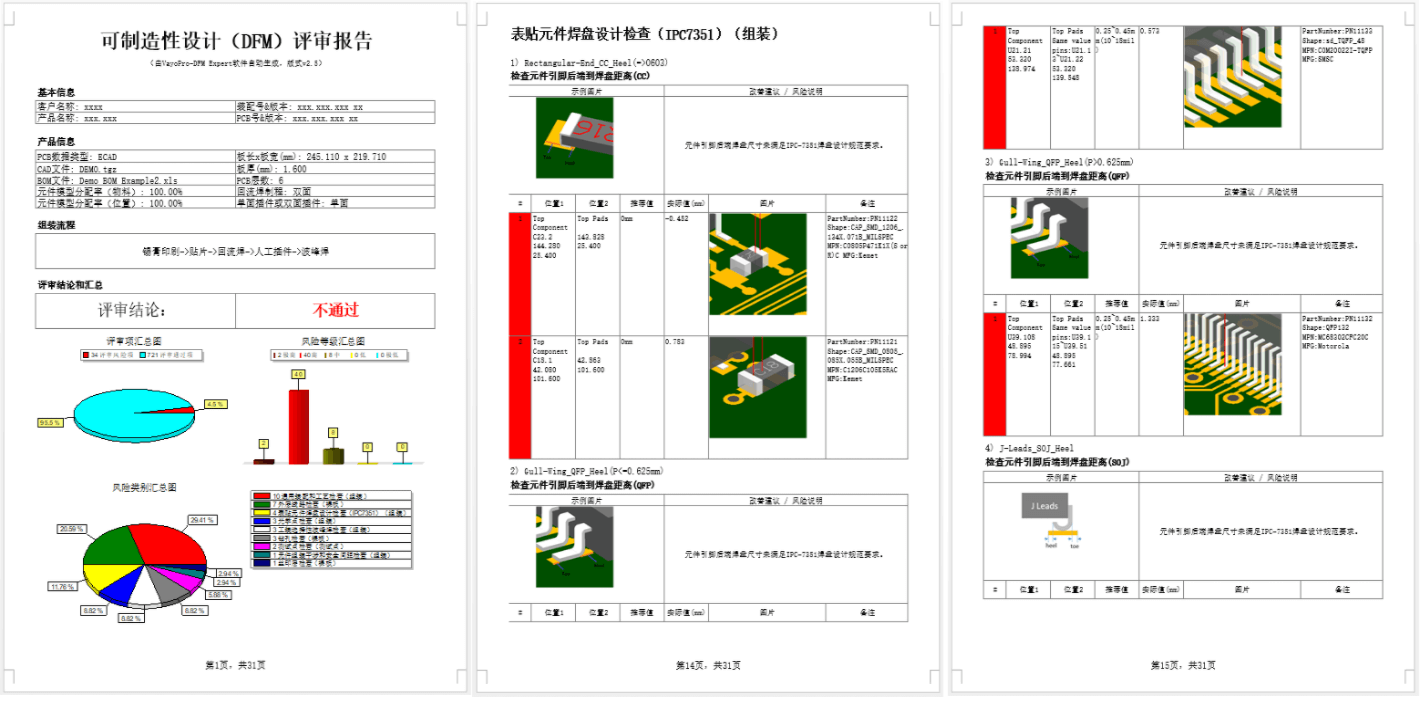

- PCB manufacturability analysis report

- Check parameter 2

- Check parameter 1

- Comprehensive inspection rules

Testing and equipment

Quality certification

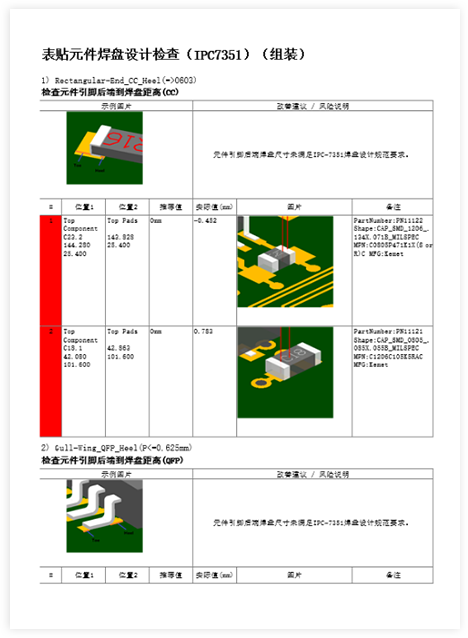

Our PCBA product demonstration

Our Workshop

Would you like us to provide DFMA service for you?

Quotationwhy you choose us?

-

Free DFMA testing service

After receiving the customer's PCB Gerber file, the professional electronic engineer will conduct a DFM inspection, promptly put forward some improvement op... -

Senior designer team

After receiving the customer's PCB Gerber file, the professional electronic engineer will conduct a DFM inspection, promptly put forward some improvement op... -

10+ years of experience

We can provide one-stop PCBA intelligent manufacturing services from PCB design, DFMA analysis, PCB manufacturing, SMT mounting, to terminal DIP plug-ins for sm...

Common problems of DFMA service

-

1What is the DFM of a printed circuit board?

Product design for manufacturability is referred to as DFM. It is the study of some design behavior rules of the relationship between the physical design of the product itself and the various parts of the manufacturing system, and it is used in product design to integrate the entire manufacturing system for overall optimization.

As we all know, the design stage determines 70%-80% of the manufacturing cost of the product. Similarly, many quality characteristics are also fixed during the design. Therefore, it is very important to fully consider the manufacturing factors during the design process.

Good DFM is an important link for product manufacturers to reduce manufacturing defects, simplify manufacturing processes, shorten manufacturing cycles, reduce manufacturing costs, optimize quality control, enhance product market competitiveness, and improve product reliability and durability. It can enable enterprises to obtain the best benefits with the least investment and achieve a multiplier effect with half the effort.

The most important thing for SMT chip processing circuit board products is product reliability. Reliability is the basis of SMT chip processing and production. Reliability is an important indicator of circuit board products. In the past, reliability was neglected. When the car is running, the circuit board wires transfer to each other, increasing heat energy. If the product does not consider safety and the circuit board fails during operation and causes a car accident, then the problem will come. Is the reliability setting of the circuit board important?

The answer is yes, the purpose of reliability design is to achieve the required reliability at the least cost.

Reliability is an important indicator of electronic products. Product reliability not only affects the future of SMT chip processing and production enterprises, but also directly affects the value of the product. Especially for military communication equipment, it has special significance.

The reliability design of the printed circuit board is very complicated, and the content of the reliability design is many, such as thermal design, drift design, anti-interference design, protection circuit design (anti-vibration design, three-proof design), SMT process design, safety design, man-machine System design, reliability review and value analysis, reliability experiment and reliability evaluation, etc.

Therefore, for high-end electronic products, for safety and product value, SMT circuit board manufacturers need to design circuit boards for reliability.

The above is the introduction of what is the DFM of the printed circuit board. I hope it can help you. At the same time, if you want to know more about the information of the printed circuit board, you can pay attention to the update of KFPCBA.

-

2Analysis of the role of DFM in the PCBA production process

DFM is the abbreviation of Design for Manufacturability (design for manufacturability), which mainly studies the relationship between the physical design of the product itself and the various parts of the manufacturing system, and uses it in product design to integrate the entire manufacturing system for an overall optimization. DFM can reduce the development cycle and cost of the product, so that it can be put into production more smoothly.

PCBA DFM is to make the necessary analysis of the reliability and feasibility of PCBA processing and production when new PCBA products are introduced into production. As a PCB designer, you must consider the requirements of different stages in the PCBA production process and the use of the finished product. Should consider things such as functionality, circuits and machinery. In addition, the PCB layout should reduce costs while ensuring quality as much as possible. There is also the DFM part. This part is the lowest cost of PCBA production errors. You should consider the following aspects:

· PCB material selection;

· Impedance;

· Drill bits and gaskets;

Surface treatment

· Copper layer and copper are evenly distributed;

· Whether to achieve the best electrical performance;

· There are no parts in the restricted area;

Heavy parts are placed near the PCB bracket or edge, etc. ...

-

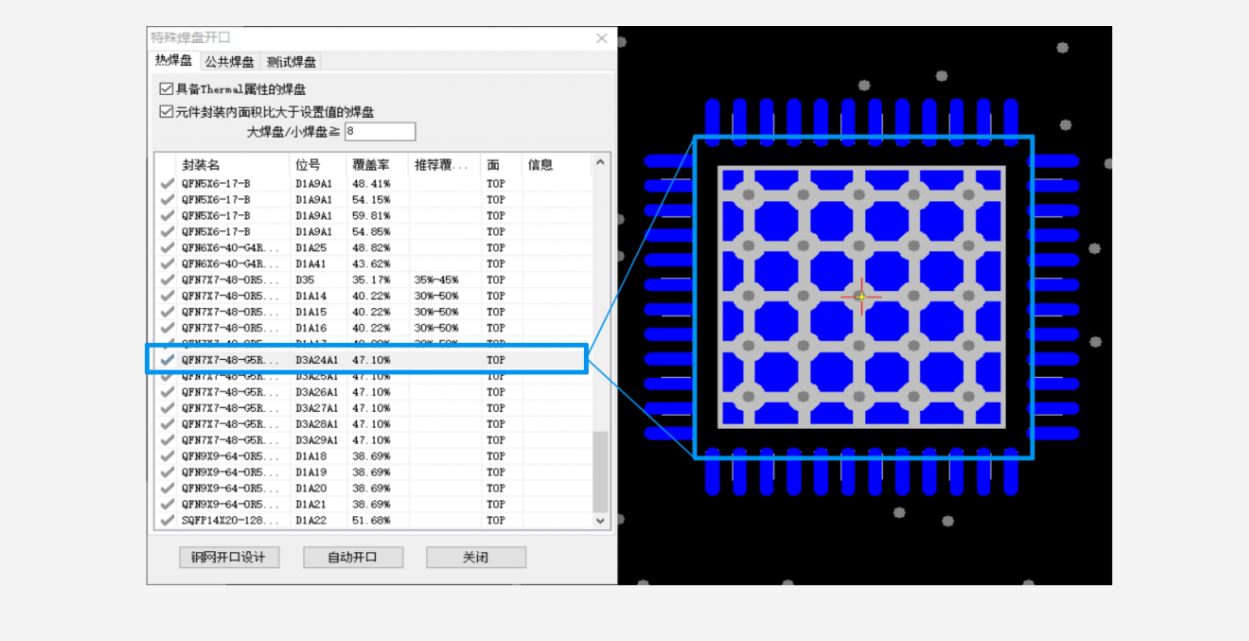

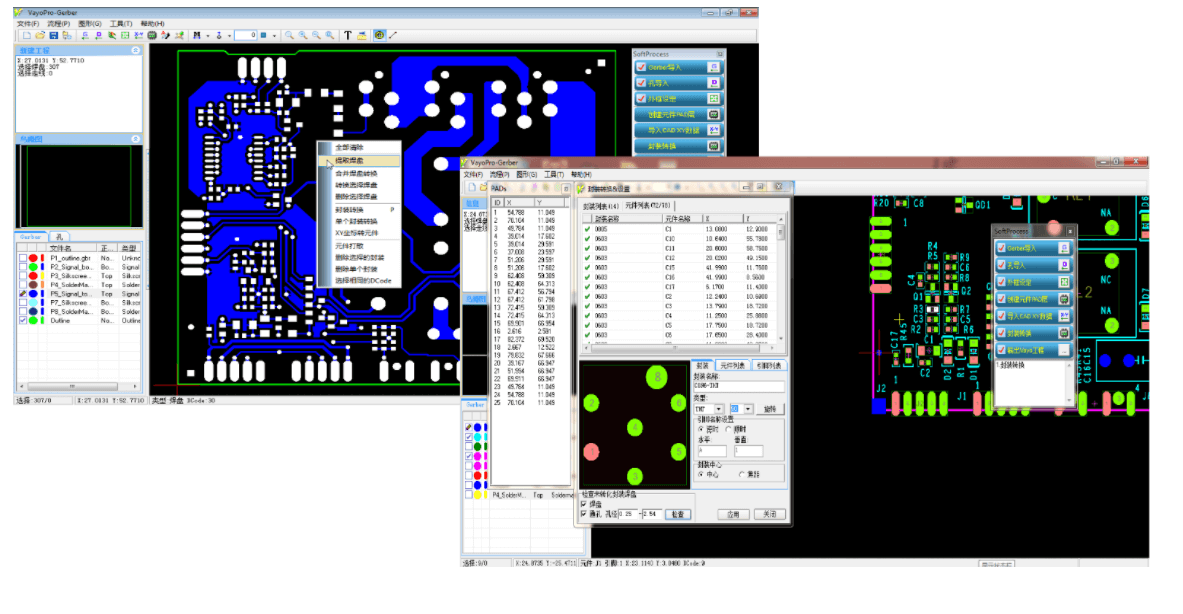

3What are the advantages of the KFPCBA DFM tool?

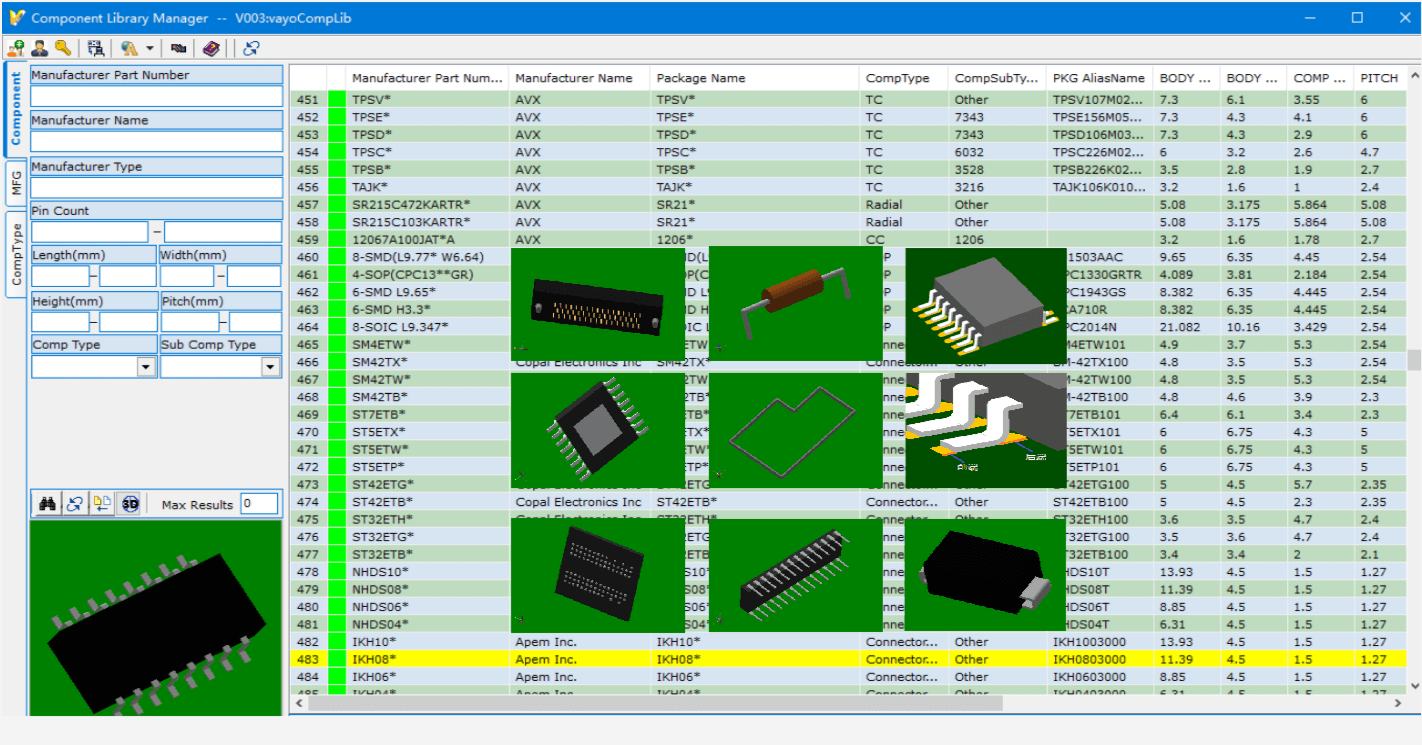

Support parsing formats such as Allegro, Altium, Protel, PADS, OBD, Gerber, etc.;

Automatically analyze design hazards, eliminate production difficulties, design defects, and warn about price factors;

Online price evaluation, you can easily understand the cost dynamics;

Portable view, view files with friends and colleagues anytime, anywhere;

23+ manufacturing analysis, the higher the score, the more standardized the design;

Analyze the detailed list, and there is a direction and basis for optimization and adjustment.

-

4What are the application scenarios of KFPCBA DFM?

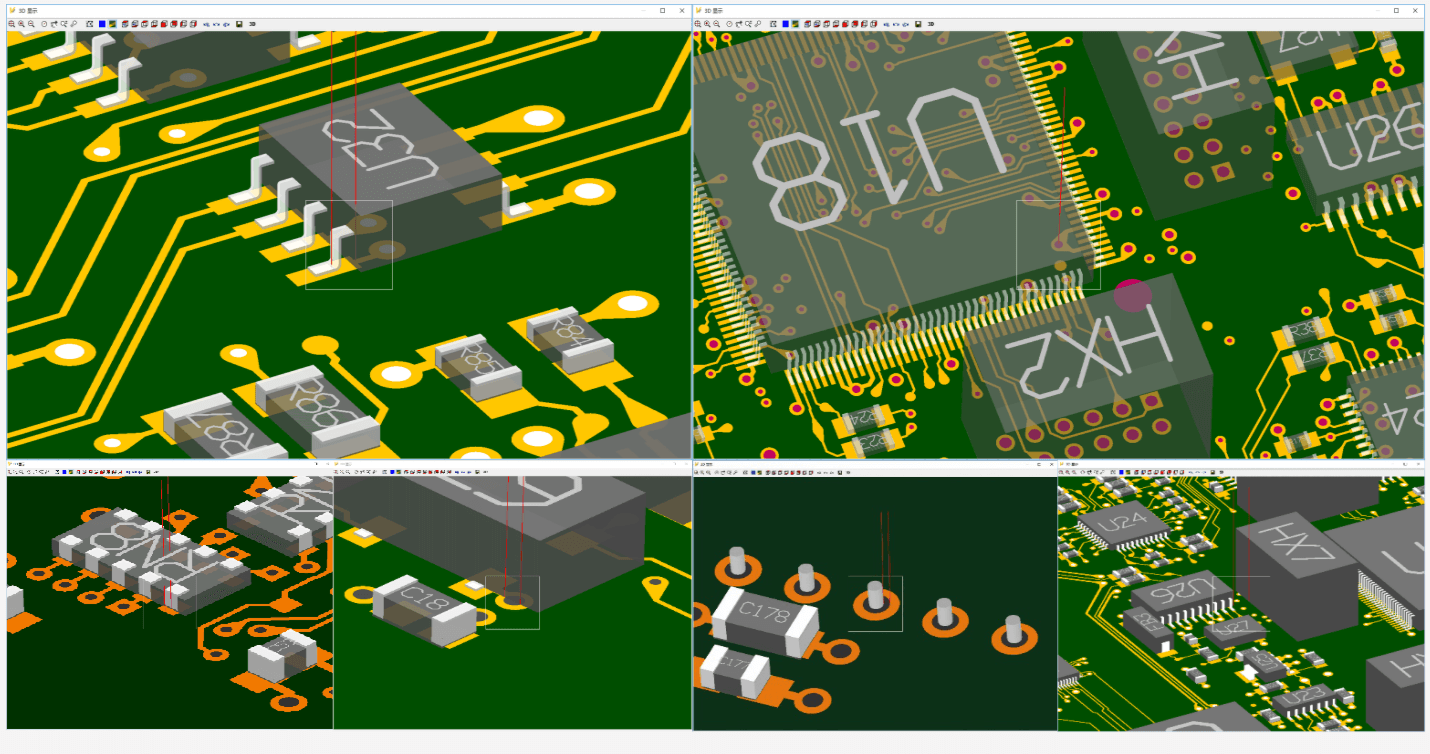

Problem location-easy to locate and view the location of hidden danger details

Optimization Suggestions-Propose reasonable optimization plans for problems and price-influencing projects

Component search-quickly and accurately locate the location of components, the quality of multi-layer PCB boards is more reliable

Automatic stacking-automatically matching the stacking that meets the production, the quality of multi-layer PCB boards is more reliable

Impedance artifact-combined with various production factors, automatically calculate or inverse impedance

BOM analysis-check whether the various parameters of the component are correct, and replace the complicated operation of Excel

-

5How does KFPCBA DFM charge?

KFPCBA DFM’s original intention is to bring revolutionary changes to the PCB industry. It aims to help engineers standardize design, discover and correct design hazards in advance, so as to shorten the development cycle, improve quality, save costs, and promote the rapid and steady development of the electronics industry.

At present, KFPCBA DFM can be used free of charge for the PCB Layout design engineers of old customers forever.

tel:+86-18825224069

tel:+86-18825224069 email:

email: