address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

Brief analysis: What are the precautions for SMT patch processing?

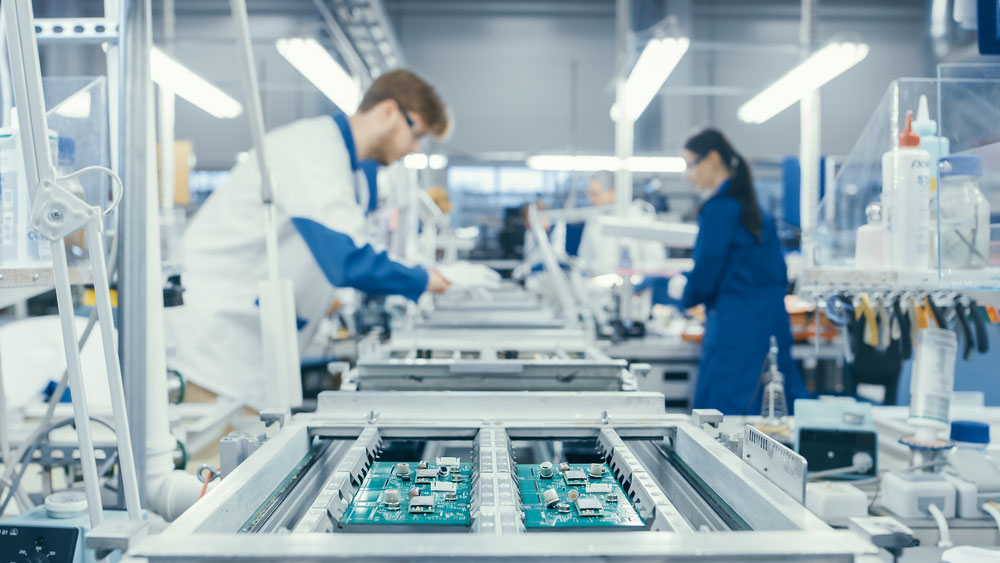

As the most popular assembly technology in the electronics industry, SMT chip processing has the characteristics of small electronic products, high assembly density, high reliability, strong shock resistance, good high-frequency characteristics, and reliable performance. Widely used in medical electronics, smart home, automotive electronics, 5G communications and other industries, SMT patch processing technology can effectively save costs and improve production efficiency, so today, let’s take a look at what are the precautions for SMT patch processing~

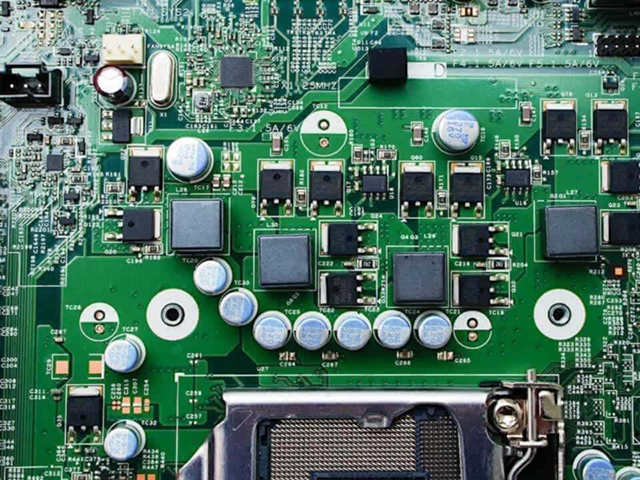

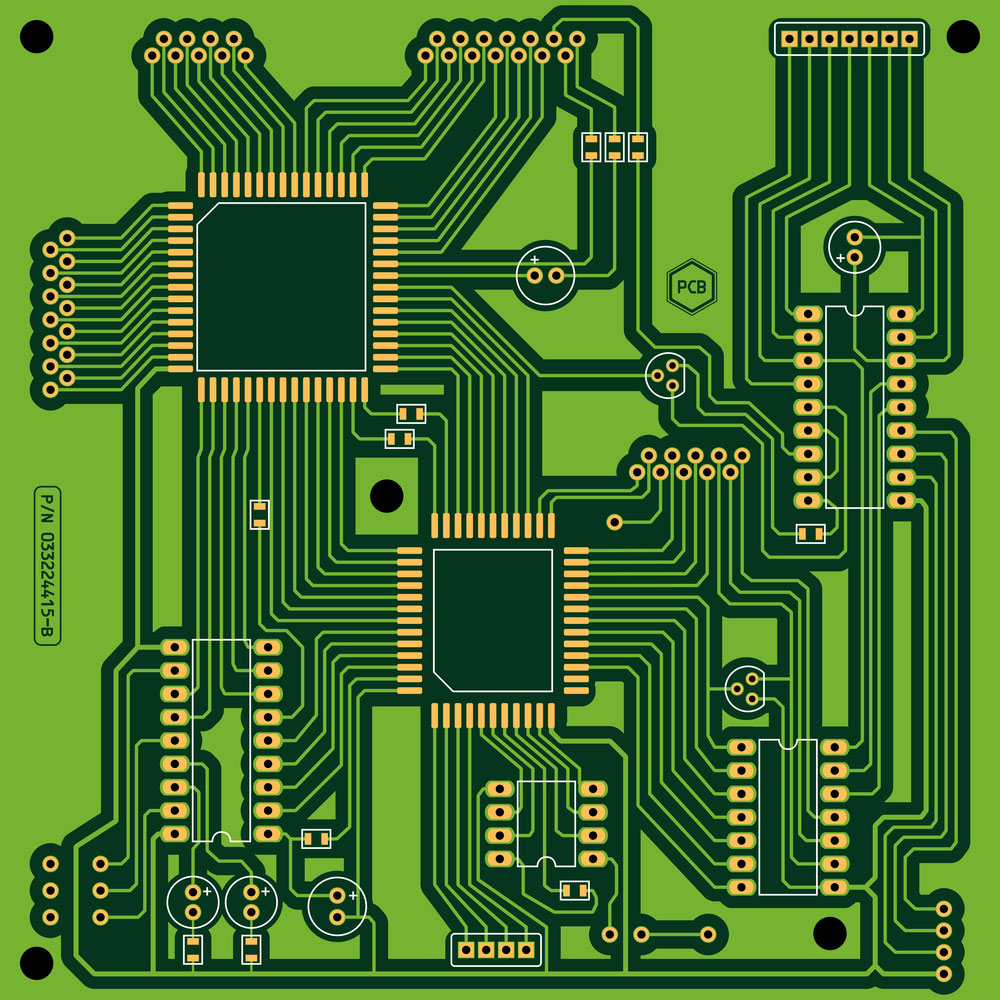

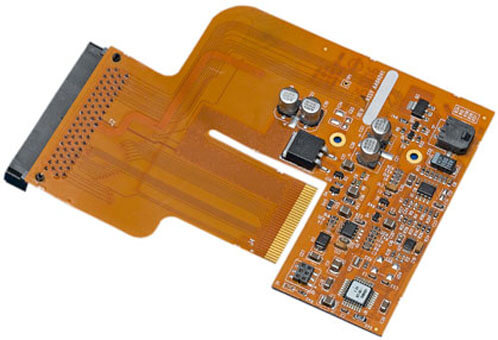

SMT chip processing is to paste the components on the PCB printed with glue or solder paste through the placement machine, and then solder through reflow soldering. The solder paste is mainly used for the surface resistance of electronic components in the SMT chip industry, capacitors, ICs and other electronics. For the soldering of components, when buying solder paste, it is recommended to put it in the refrigerator for refrigeration if it is not used. The temperature should be kept at 5℃-0℃, not lower than 0℃; used old solder paste; solder paste after opening the lid It is recommended to use it up within 12 hours. If you need to store it, please fill it with a clean empty bottle, and then seal it back to the freezer for storage.

During the placement, in order to ensure the normal operation of the placement machine, it is necessary to carefully check whether the feeder is intact, whether the suction nozzle is blocked or damaged, etc.; in order to ensure the quality of the PCB board welding, two furnace temperature tests are required to achieve the placement And the temperature curve of welding products; in order to ensure the quality of placement, the factory workshop temperature, humidity, and environmental standards must be strictly implemented.

SMT patch processing has many operating procedures, involving many process technologies, and not only the above points. These require the operators to learn and understand in depth, master the main points, and avoid errors. Kuaifa Zhizhi focuses on small and medium batch SMT SMD proofing, pcb proofing, etc., provide one-stop PCBA intelligent manufacturing service, SMT patch proofing, in Kuaifa Zhizao, it has realized a piece of starting, no threshold, full-process process service, SMT patching, post-welding DIP plug-in, pcb manufacturing, test assembly, etc., KFPCBA, can solve it for you in one stop!

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: