address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

Multilayer PCB Prepreg- A Detailed Explanatio

Insulation is a critical activity in the manufacture of PCBs. For this reason, there's a wide range of Multilayer PCB Prepreg materials.

We'll discuss the essence of the dielectric materials, their manufacturing process, and other crucial details.

Contents [hide]

What is Prepreg?

How are Prepregs Made?

How to Choose Prepreg in PCB Design and Fabrication?

How is Resin Content in Prepreg and Laminates Measured?

What is the Difference Between Prepreg and Core?

The Difference Between Prepreg and Laminate

Conclusion

What is Prepreg?

Fig 1: A self-made circuit board

A prepreg PCB is any material fit for use as an insulation layer in an electronic circuit. Therefore, you can regard it as a binding dielectric material as it connects two copper foils or two cores.

Also, you can modify prepreg PCB to suit your needs. For instance, you can add catalysts and additives via a chemical process to change a part of the prepreg to a conductive zone.

Such a transformation enables selective conductivity, a process that is handy in making holes into the prepreg for connection purposes.

How are Prepregs Made?

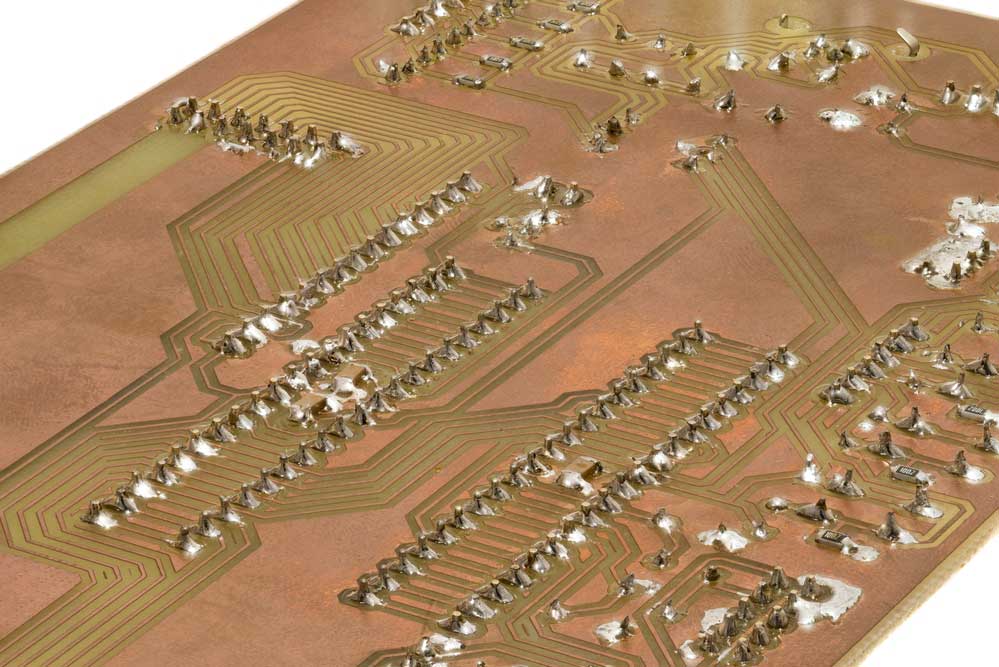

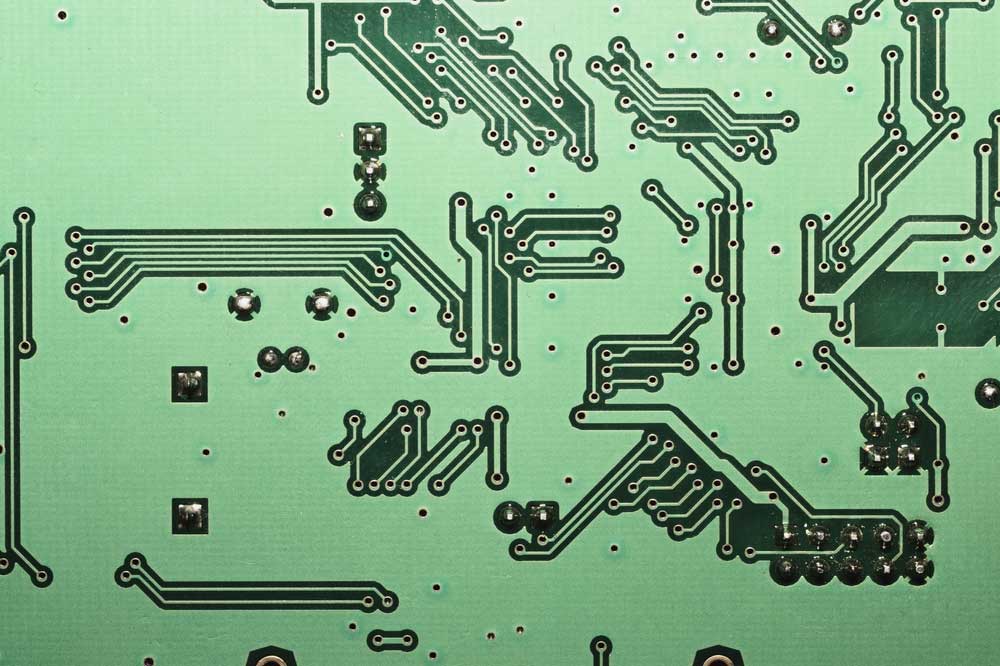

Figure 2: Components in a self-made circuit board

The PCB manufacturing process of prepreg comprises filling a cloth or glass fiber weave using a resin bonding agent. Note that the glass fiber cloth, in this case, has undergone partial drying to make a B-stage material.

In addition, it's imperative to align with the grain direction of the prepreg materials you are using during the manufacturing procedure. It aids the modification of prepreg according to the requirements.

Lastly, remember the amount of standard resin the glass fabric can hold relies on the warp and fills in the prepregs.

How to Choose Prepreg in PCB Design and Fabrication?

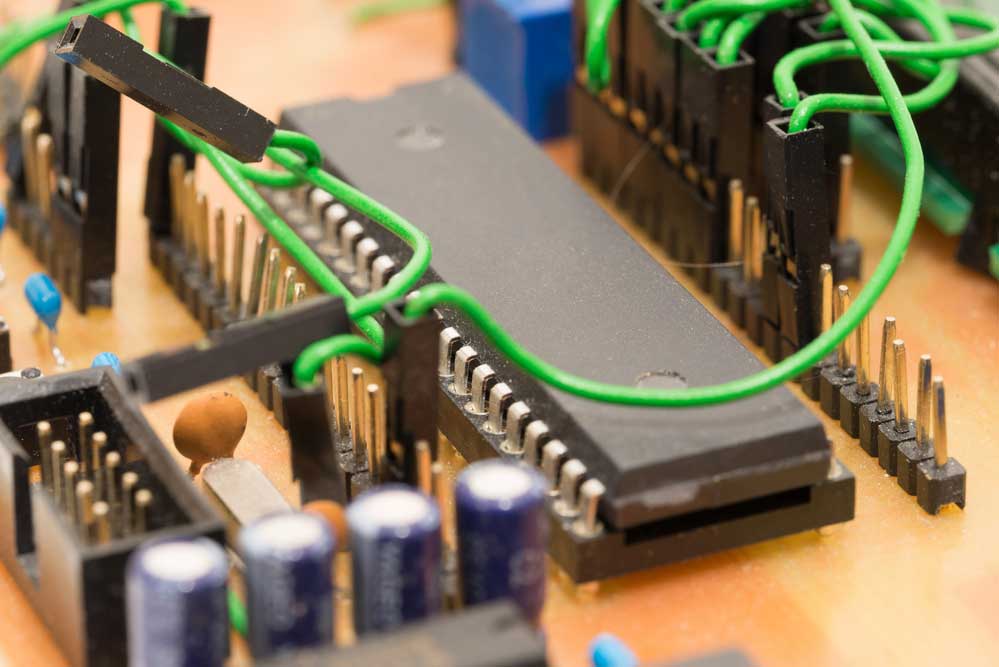

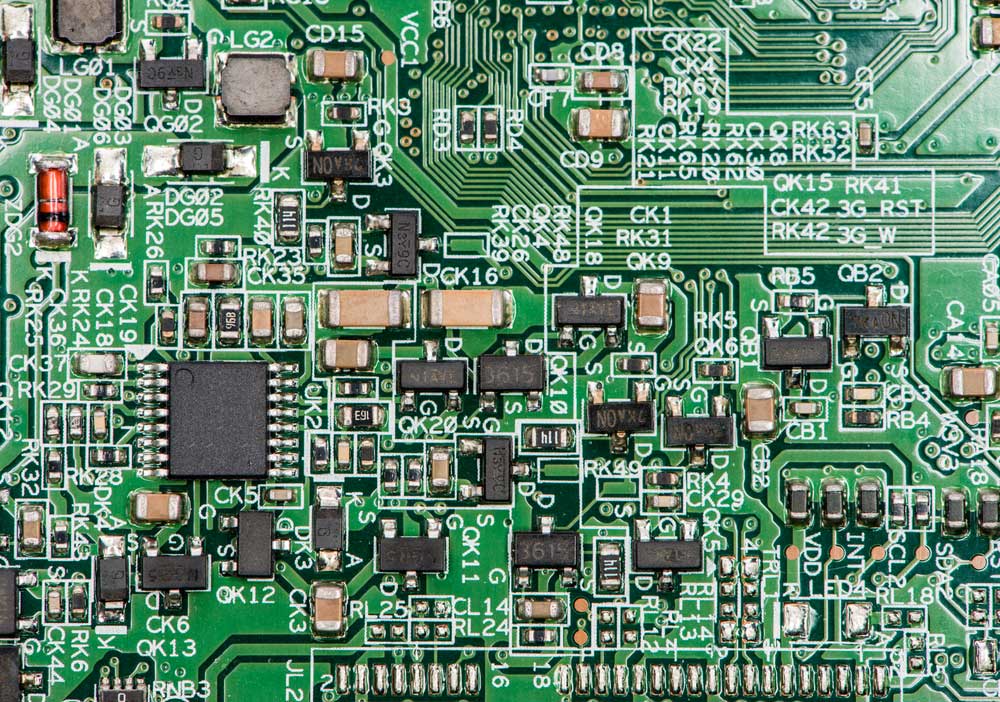

Figure 3: a self-made printed circuit board with a microcontroller

There's an extensive array of prepregs in PCBs with different features such as thickness. Generally, we can either classify prepregs as follows:

Standard Resin (SR)

Medium Resin (MR)

High Resin (HR)

The classification above relies on the amount of foreign matter (resin) the prepregs hold. Therefore, a hardened resin/ high resin prepreg is pricier than a standard resin prepreg.

How is Resin Content in Prepreg and Laminates Measured?

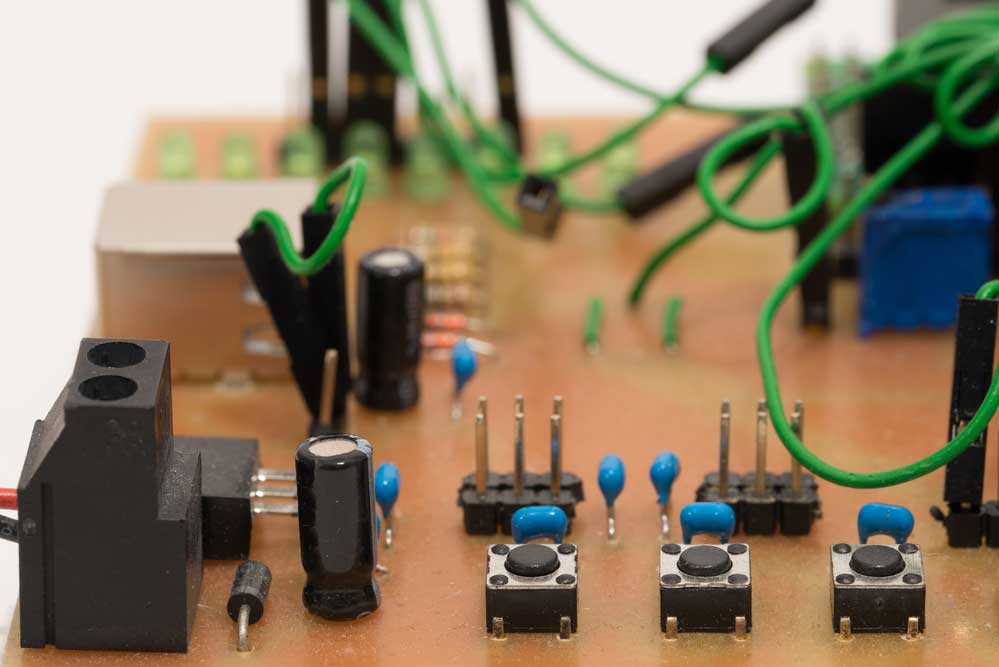

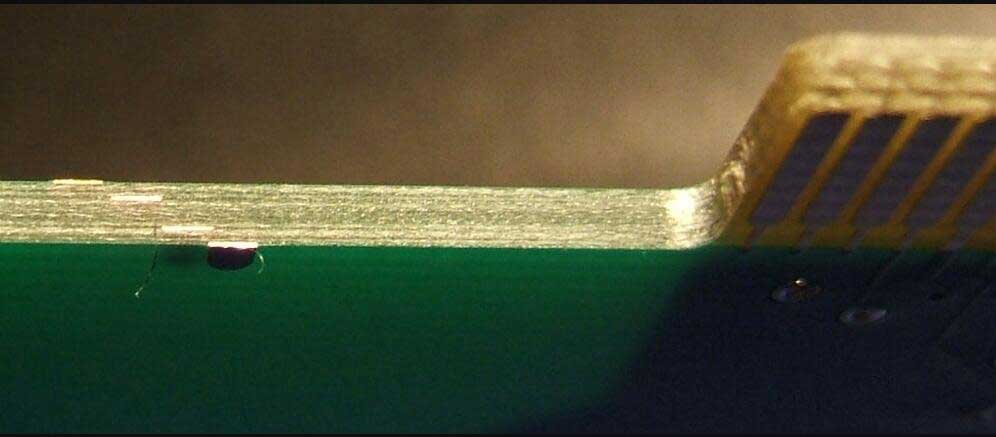

Figure 4: A PCB

The resin content refers to the proportion of the amount of resin to the prepreg's overall weight. You can measure the resin content as follows.

First, measure the prepreg specimen's initial weight.

Dissolve the resin in a solvent by immersing it in LR-grade sulphuric acid for about 10 seconds.

Next, wash the prepreg specimen with water to remove the excessive resin powder and dry it.

Lastly, obtain the specimen's weight. The difference in the final weight from the initial weight is the weight of the core layers of the resin.

Using the equations below, you can also obtain the resin percentage resin content:

% resin material = Weight difference/ original prepreg weight x 100.

The resin content is a primary determinant of the thickness of the laminate upon pressing. Also, it has a significant impact on aspects such as

Dielectric constants

Etching quality

Drilling

What is the Difference Between Prepreg and Core?

Figure 5: Electronic circuit board abstract background.

The core is an amalgam of prepreg and lamination. Therefore, the core is more rigid than the average PCB prepreg. Also, the core comprises a flame retardant grade fiberglass-epoxy laminate with copper traces on either side.

Here are a few outstanding differences:

The Prepreg can be of the same material as a core. However, prepregs undergo partial drying with no lamination, making them less rigid than cores.

Besides, when you use them as dielectric constants (DK), the core materials' DK remains the same. On the flip side, the dielectric constant of the prepreg before and after lamination is different.

Thirdly, the prepreg is a sticky, not capacitive, and it's a dielectric material. However, a core is the primary PCB material. Therefore the functions of the two are entirely different.

The Difference Between Prepreg and Laminate

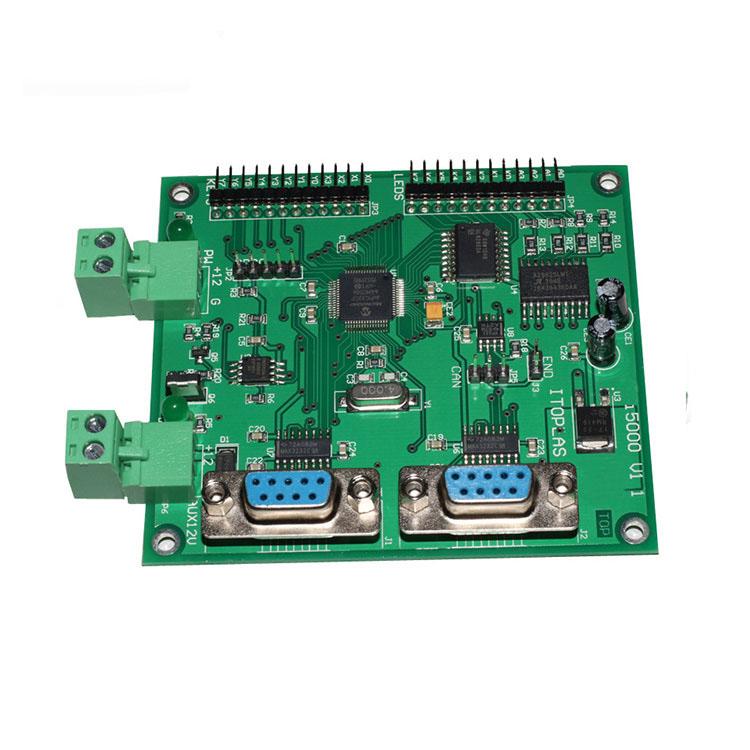

Figure 6: PCB with electronic Components

The table below lists the differences between prepreg and laminate:

Conclusion

In a nutshell, a PCB prepreg is a material/ insulator that separates cores and copper foils. Also, all PCB electrical components must have prepreg. For additional queries, please reach out to us.

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: