address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

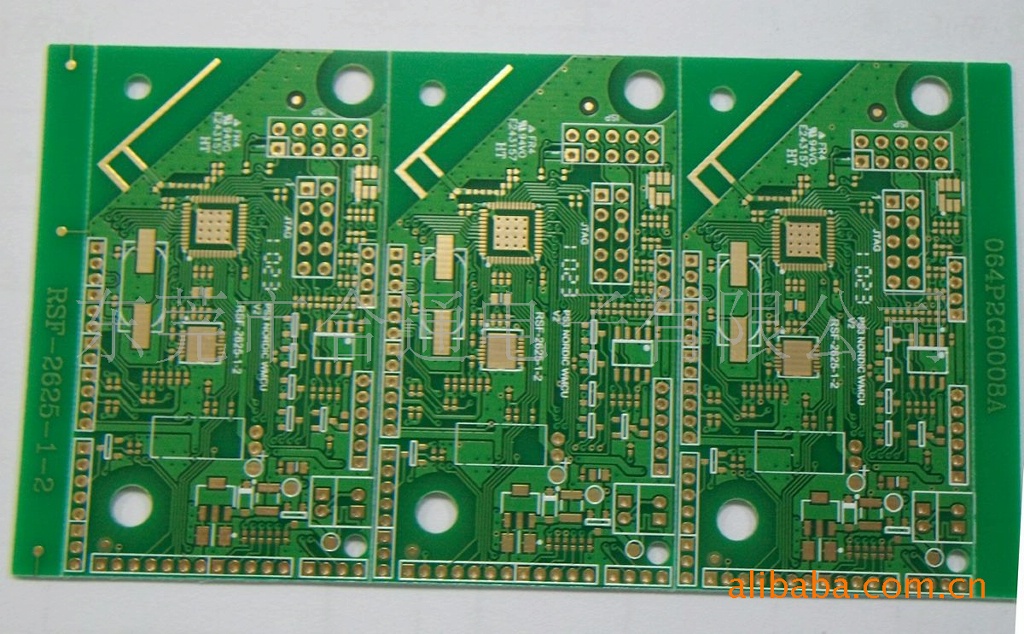

What is PCB Assembly?

pcb assembly work from home

Do you love working with your hands? Do you have a steady hand and an eye for detail? Then you might be interested in a career in PCB assembly! PCB assembly is the process of creating circuit boards. These boards are used in all sorts of electronic devices, from computers to cell phones. If you’re thinking about a career in PCB assembly, there are a few things you should know. First, it’s important to have a steady hand and good attention to detail. You’ll also need to be able to work with small parts and be comfortable using a microscope. Another important thing to keep in mind is that PCB assembly is often done in clean rooms. This means that you’ll need to be able to follow strict protocols and wear protective clothing. If you’re interested in pursuing a career in PCB assembly, there are plenty of resources available to help you get started. There are online courses, training programs, and even certification programs available. And with the right training, you can start working from home as a PCB assembly contractor!

What is PCB Assembly?

PCB Assembly is the process of connecting electronic components to a Printed Circuit Board (PCB) using wires, solder, and other conductive materials. The goal of PCB Assembly is to create a working circuit board that can be used in various electronics devices.

There are many steps involved in PCB Assembly, but the basic process can be broken down into four main stages:

1. Preparing the PCB

The first step in PCB Assembly is to prepare the printed circuit board. This involves cleaning the board and applying a thin layer of copper to the surface. The copper helps to conduct electricity and provides a surface for the components to be attached to.

2. Attaching the Components

Once the PCB is prepared, it's time to start attaching the electronic components. This is done by soldering the component leads onto the copper pads on the PCB. It's important to make sure that each lead is properly connected before moving on to the next component.

3. Testing the Circuit Board

After all of the components have been attached, it's time to test the circuit board. This can be done by powering up the board and testing each component individually. If everything appears to be working correctly, then Congrats! Your circuit board is now complete!

The Different Types of PCB Assembly

There are different types of pcb assembly. The two main types are through-hole and surface-mount.

Through-hole: Through-hole pcb assembly is when the electronic components are inserted into holes that have been drilled into the pcb. Solder is then applied to the leads of the components to hold them in place and make electrical connection between them. This type of assembly is typically used for larger components that can not be mounted on a surface-mount pcb.

Surface-mount: Surface-mount pcb assembly is when the electronic components are mounted on the surface of the pcb. Solder is then applied to the leads of the components to make electrical connection between them. This type of assembly is typically used for smaller components that can be mounted on a surface-mount pcb.

Pros and Cons of PCB Assembly from Home

When it comes to printed circuit board (PCB) assembly, there are pros and cons to doing the work from home. Here are some things to consider before making a decision:

Pros:

-You can save money on expensive equipment and space rental costs.

-You have complete control over your work environment, which can be important for quality control.

-You can work at your own pace and schedule.

Cons:

-You may need to invest in some basic equipment, such as a soldering iron and tools.

-You may need to invest in materials, such as PCBs, components, and solder.

-You will be responsible for all aspects of the assembly process, including quality control.

What is Needed to Assemble a PCB at Home?

In order to assemble a printed circuit board (PCB) at home, you will need the following:

-A Printed Circuit Board (PCB)

-A soldering iron and solder

-A desoldering tool (optional)

-Wire cutters

-Tweezers

-A magnifying glass or other magnification device (optional)

-A well-ventilated work area

First, you will need to gather all of the necessary tools and materials. Once you have everything you need, find a well-ventilated work area where you can set up your workspace. Next, take a look at the PCB design and familiarize yourself with the layout of the components. Then, begin soldering the components to the board, starting with the larger ones first. If you make a mistake or need to remove a component, you can use a desoldering tool. Once all of the components are in place, carefully inspect your work to make sure everything is correct. Finally, give the board a final cleaning and it's ready to use!

How to Assemble a PCB from Home

If you're interested in learning how to assemble PCBs from home, there are a few things you'll need to get started. First, you'll need a printed circuit board (PCB) design and the necessary components. Once you have those, you can follow these simple steps to assemble your PCB:

1. Clean your work area and lay out all of the components for your project.

2. Inspect each component for any damage or defects.

3. Solder each component onto the PCB according to the design layout.

4. Inspect your work for any shorts or other issues.

5. Test your assembled PCB to make sure it's working properly.

With a little practice, you'll be able to assemble PCBs from home quickly and easily!

Alternatives to PCB Assembly from Home

There are a few alternatives to PCB assembly from home that you can consider if you're looking for a more professional or reliable method of assembly. One option is to use a contract manufacturer that specializes in PCB assembly. This can be a great option if you don't have the time or resources to do the assembly yourself, and it can also be more cost-effective in some cases.

Another alternative is to use an online service like BatchPCB. This allows you to upload your design files and have them assembled by professionals, with no need for you to do any of the work yourself. This can be a great option if you want to be sure that your boards are assembled correctly and reliably.

Finally, you could also consider building your own small-scale assembly line at home. This can be a bit more work but can also be more rewarding, as you'll have complete control over the process and will be able to ensure quality control.

Conclusion

There are plenty of reasons to consider working from home in the pcb assembly industry. With the right skills and equipment, you can be your own boss and set your own hours. You can also save money on commuting costs and child care. And, if you're good at what you do, you can earn a decent income. If you're thinking about starting a pcb assembly business from home, be sure to do your research and create a well-thought-out business plan.

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: