address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

PCB manufacturing process- Everything You Need to Know

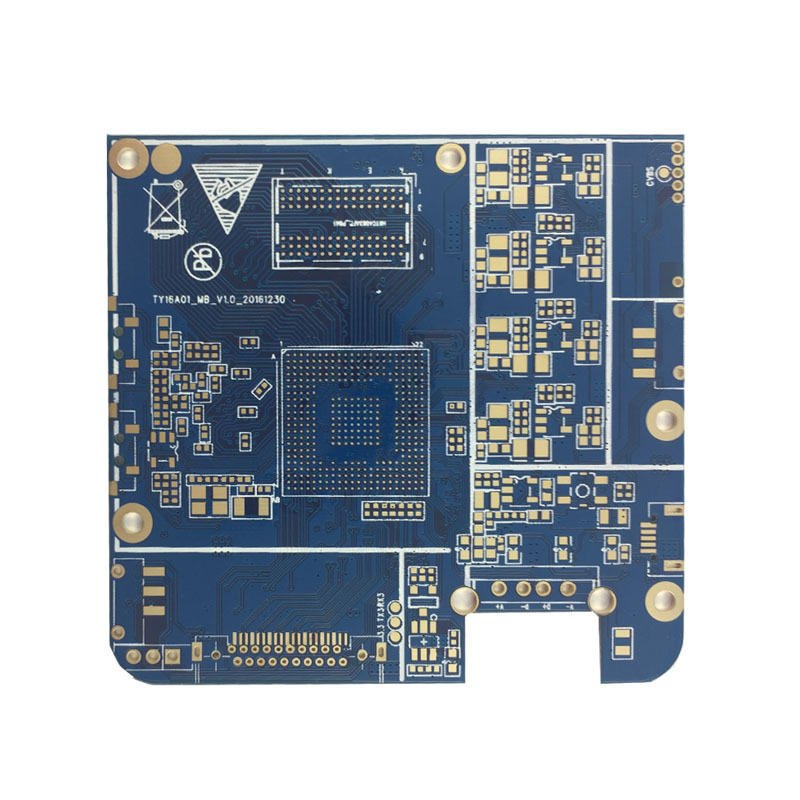

PCBs or Printed Circuit Boards are essential components in modern electronic devices. From smartphones to medical equipment, the manufacturing process of these intricate circuit boards plays a crucial role in the performance and reliability of the devices. In this article, we will dive deep into the PCB manufacturing process, including the different techniques involved, the types of materials used, and the challenges faced by manufacturers. Whether you’re a seasoned engineer or a curious learner, this article will provide you with everything you need to know about the PCB manufacturing process.

Section 1:Introduction to PCB Design

Printed Circuit Board (PCB) design involves creating a layout for an electronic circuit board that serves as a platform for various electronic components. PCB design plays a crucial role in the development and manufacturing of electronic products.

Software used in PCB Design

PCB design software is used to create and edit the layout of a PCB. Popular software includes Altium Designer, Eagle PCB, and KiCAD.

Types of PCB Designs

There are various types of PCB designs, including single-sided, double-sided, and multi-layered designs. The choice of design depends on the complexity of the circuit and the space available.

Design Rules and Constraints

Design rules and constraints dictate the minimum size and spacing of the components on the PCB. These rules ensure that the design is manufacturable and meets the required performance specifications.

Design for Manufacturing (DFM)

DFM is a set of guidelines that aim to improve the manufacturability of a PCB design. DFM considerations are important in ensuring that the design can be produced reliably and cost-effectively.

Section 2: PCB Materials

Types of PCB Materials

PCB materials include copper-clad laminates, epoxy resins, and various reinforcing materials such as glass fibers. The choice of material depends on the requirements of the design.

Properties of PCB Materials

PCB materials possess various properties such as electrical conductivity, thermal conductivity, and dielectric constant. These properties determine the suitability of the material for specific applications.

Advantages and Disadvantages of Different PCB Materials

Different PCB materials have their advantages and disadvantages. For instance, FR-4 is a popular material due to its low cost and good electrical properties, but it has limited temperature tolerance.

How Material Choice Affects PCB Performance

The choice of PCB material affects the electrical and thermal performance of the PCB. Factors such as signal integrity, power dissipation, and thermal management must be considered when selecting a material.

Section 3: PCB Manufacturing Techniques

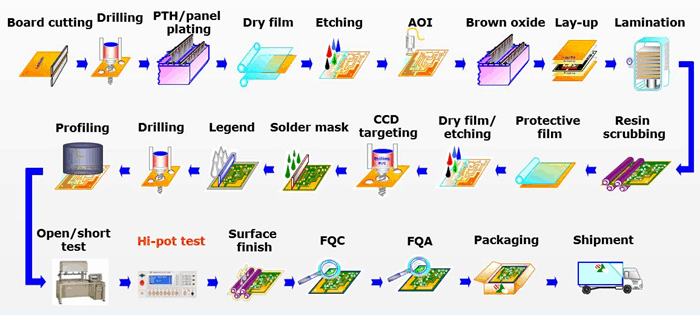

Overview of PCB Manufacturing Techniques

PCB manufacturing techniques include etching, drilling, plating, soldering, and inspection/testing. These techniques are used to fabricate the PCB from the design files.

Etching

Etching is a process used to remove unwanted copper from the PCB. The process involves applying a resist layer to the copper, exposing the desired areas, and then etching away the unwanted copper.

Drilling

Drilling is used to create the holes on the PCB. These holes are used for component placement and interconnects between the different layers of the PCB.

Plating

Plating involves depositing a layer of metal (usually copper) onto the PCB. This layer is used to provide electrical connectivity between the different components and layers of the PCB.

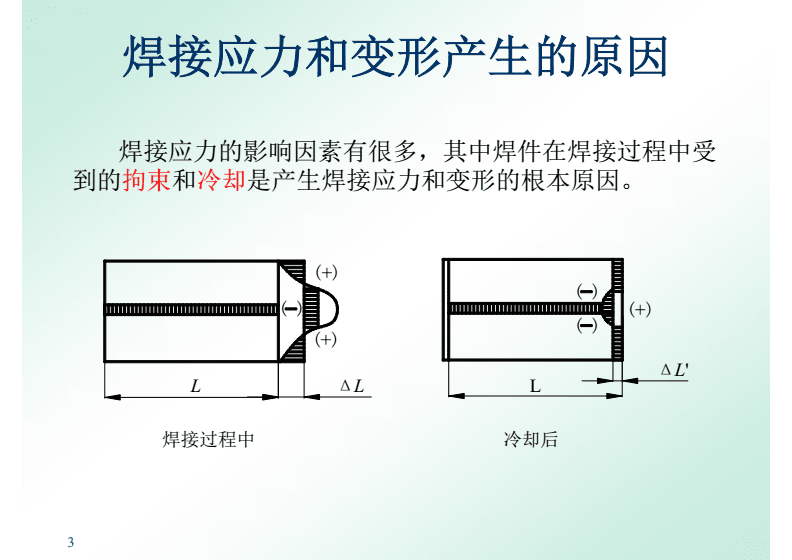

Soldering

Soldering is used to attach components to the PCB. This process involves heating the solder paste and components, causing the solder to flow and create a strong mechanical and electrical bond.

Inspection and Testing

Inspection and testing are crucial in ensuring that the PCB meets the required quality standards. Techniques such as visual inspection, X-ray inspection, and electrical testing are used to ensure that the PCB is functional and reliable.

Section 4: Challenges and Solutions in PCB Manufacturing

Common Challenges in PCB Manufacturing

PCB manufacturing faces various challenges, including component placement, thermal management, and signal integrity issues. These challenges can result in manufacturing defects, delays, and high costs.

Solutions to Overcome These Challenges

Solutions to overcome these challenges include using automated assembly processes, designing for thermal management, and using signal integrity simulation tools. These solutions help to improve the efficiency, reliability, and quality of the PCB manufacturing process.

Section 5: Industry Applications and Trends

Applications of PCBs in Various Industries

PCBs are a crucial component in many modern electronic devices and play a critical role in a range of industries. Here are some of the most prominent applications of PCBs in various industries:

Consumer Electronics: PCBs are commonly used in smartphones, televisions, laptops, and other electronic devices.

Automotive Industry: The automotive industry uses PCBs in the manufacture of various components, including airbag control systems, engine control units, and anti-lock brake systems.

Medical Devices: PCBs are used in medical devices such as pacemakers, defibrillators, and heart monitors.

Aerospace and Defense: PCBs are widely used in aerospace and defense applications, including satellite communications, radar systems, and missile guidance systems.

Industrial Control: PCBs are used in industrial control systems such as robotics, motor controllers, and power inverters.

Emerging Trends in PCB Manufacturing and Design

The PCB industry is continually evolving, and manufacturers are always seeking new and innovative ways to produce high-quality PCBs efficiently. Here are some emerging trends in PCB manufacturing and design:

Miniaturization: With the demand for smaller and more compact devices increasing, manufacturers are developing PCBs with smaller components and tighter trace widths.

Flexible PCBs: Flexible PCBs are becoming increasingly popular in many applications, including wearables, medical devices, and automotive applications.

3D Printing: 3D printing technology is becoming more advanced and accessible, allowing manufacturers to produce complex PCB designs quickly and cost-effectively.

Environmentally-friendly PCBs: PCB manufacturers are exploring new and sustainable materials and manufacturing processes to reduce the environmental impact of PCB production.

Environmental Concerns and Sustainable PCB Manufacturing

PCB manufacturing involves the use of various chemicals and materials that can be harmful to the environment. For instance, PCBs contain lead, a hazardous material that can have long-term health effects on humans and animals. Additionally, the manufacturing process generates waste products that can contaminate soil and water sources.

To address these concerns, manufacturers are exploring new ways to produce PCBs sustainably. Some strategies include using lead-free materials, recycling PCB waste, and implementing closed-loop manufacturing processes that minimize waste and resource consumption.

Section 6: Conclusion

Recap of the Key Points in PCB Manufacturing

In this article, we have covered the basics of PCB design, materials, manufacturing techniques, and industry applications. We have also discussed emerging trends in PCB manufacturing and design and the importance of sustainable PCB production.

Final Thoughts on the Importance of the PCB Manufacturing Process

PCBs are an integral part of modern electronics and play a critical role in many industries. A well-designed and manufactured PCB can significantly impact the performance and reliability of electronic devices. As technology continues to advance, the demand for more advanced PCBs will increase, making PCB manufacturing an essential industry.

Resources and Links for Further Reading

If you are interested in learning more about PCB manufacturing and design, here are some useful resources:

IPC - Association Connecting Electronics Industries

Printed Circuit Design and Fab Magazine

PCB Design & Layout Services by Altium

PCBShopper - A Price Comparison Site for Printed Circuit Boards

We hope that this article has provided a comprehensive overview of PCB manufacturing and design and has helped you understand the critical role that PCBs play in the electronics industry.

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: