address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

What is a water level sensor PCBA?

A recent study shows that the global population at risk of flooding has increased since 2000. Therefore, people in at-risk countries must have water level detection systems. Water level sensors are one of the most readily available and cheapest tools for liquid level detection. Additionally, you can even buy or create your IoT sensor PCBA to interact with your innovative technology. However, this guide will explore what water level sensor PCBAs are, why they are important and how to incorporate them into your daily life.

What is a water level sensor PCBA?

Water Level Sensor PCBA (AKA Fluid or Level Sensor) detects and measures the amount of liquid in a container, tank or area. People unknowingly use technology that includes some kind of water level sensor every day. For example, mechanisms that measure and monitor vehicle fuel levels use water/fluid/fluid level sensors. So we can speculate that the water level sensor uses this example to evaluate the level of liquid (water) in a container or area.

Brake fluid reservoir using fluid level sensor

We can also use them to alert us when fluids reach a certain level. In addition, the water level sensor can trigger an automatic response from the machine. For example, flashing a light when the liquid reaches a certain level, or activating a drain or other water level control device.

How does the water level sensor PCBA work?

There are many different types of water level sensors. However, they all fall into two main categories. They can be point level measurement sensors or continuous level measurement sensors. Water level sensors that utilize point measurement detect when liquid is present at a specified point. Conversely, continuous level measurement sensors display a constant level as the level rises and falls.

Types of Water Level Sensor PCBA

Each classification has a different type of water level sensor. This part of the guide will explain how they work and the applications for which they are best suited. Additionally, we will discuss their limitations in certain use cases.

Types of point measurement sensors

Capacitive Water Level Sensor

A capacitive sensor is a proximity sensor PCBA that emits an electric field. It detects liquid level by observing its effect on its electric field. These sensors are small, inexpensive, accurate, and have no moving parts.

Most capacitive water level sensors consist of a long rod that you have to submerge in the liquid. Also, it would help if you calibrate them before using them. For liquids in large containers, this task can be daunting. However, they are also invasive to the product. Also, they can only detect certain liquids, which is fine if you plan to use them for water detection. However, if you plan to use them to measure levels of aggressive chemicals, we recommend against doing so.

However, capacitive level sensors are suitable for use in reservoirs. For example, water treatment facilities would be ideal applications.

Tanks that can use capacitive water level sensors

Water tank that can use capacitive water level sensor PCBA

Optical water level sensor PCBA

Optical level sensor PCBA works by converting light into electrical signals. They measure the physical part of light and then convert it into a perceptible measurement. The visual water level sensor has no moving parts. Also, high pressure and high temperature do not affect them. In some cases, they don't need to touch the liquid they measure.

They are small and we can use them in most liquid applications. However, they use lenses that get dirty easily. Therefore, it needs cleaning and maintenance from time to time. Optical level sensors are very handy in dry running conditions for fuel applications. For example, you can use them to alert you when your machine is running low on oil, coolant, or hydraulics.

Conductivity (Resistance) Water Level Sensor PCBA

Conductivity level sensor PCBA uses probes to test resistance or conductivity. The probe contains two electrodes that supply them with alternating current. When the liquid covers the search, its electrodes form part of the circuit.

This process causes current to flow. The electrical current produces a signal indicating that the liquid level is high (above a specified level) or low (below a specified level). Like capacitive water level sensors, conductive water level sensors contain no moving parts. Furthermore, they are low cost and relatively easy to use.

However, they are invasive and can only sense conductive liquids. Also, their probes corrode over time. It helps if you replace them from time to time.

Vibration (tuning fork) water level sensor PCBA

The vibrating liquid level sensor PCBA uses a fork-shaped sensing element with double tines. The part vibrates at its natural resonant frequency. As the tank/tank level changes, the frequency of the fork will also vibrate. This process allows the sensor to detect the water level in the container/tank.

tuning fork

Vibrating water level sensor PCBA is cost effective and compact. In addition, they are easy to install and low maintenance. In addition, they have a variety of liquid and material measurement applications. The mining, chemical processing, food and beverage industries use these sensors for level detection.

However, (like most point sensors) they are invasive to the liquids and materials they measure.

float switch water level sensor

Image of modern water float switch

A float switch (or level transmitter float switch) uses a device that raises or lowers when the liquid in the container/area increases or decreases. This process triggers the opening or closing of the circuit. The float switch is a non-powered device that directly indicates the water level. Also, they are inexpensive.

Unfortunately, they do have some drawbacks. For example, they are invasive, contain moving parts, and are relatively large. Also, they will only indicate when the water level has reached its highest or lowest level. Therefore, they cannot measure groups of variables.

Despite this limitation, they are still suitable for measuring liquid levels in large tanks. Also, we use them in harsh environments like lakes and dams.

Types of Continuous Level Measurement Sensors

Ultrasonic Water Level Sensor PCBA

Ultrasonic Water Level Sensors for Water Treatment Plants

Source: Creative Commons

Ultrasonic sensor PCBA works by emitting and receiving ultrasonic waves (echolocation). The time it takes for a wave to travel and return is how we measure distance. Ultrasonic water sensor PCBA is compact, contains no moving parts, and is reliable. However, they can be expensive and sometimes harm the environment.

However, one of the most significant advantages of ultrasonic sensor PCBAs is that they are non-invasive. They are usually mainly composed of stainless steel and other corrosion-resistant materials. Therefore, they do not need to be in contact with the liquid to measure it. Therefore, the properties of the fluids they measure do not affect them. Also, they clean themselves thanks to the vibrations they emit.

A good application for these types of sensors is asphalt tanks in tile manufacturing plants. We can place the sensor on top of the tank away from hot asphalt. When the bitumen level gets low, the sensor activates a mechanism that fills the tank.

Radar (Microwave) Water Level Sensor PCBA

Radar water level sensors use an antenna to transmit microwaves into the liquid. The liquid then reflects microwaves into the tank. These waves are inexplicably fast, traveling at the speed of light. The sensor PCBA uses the time between signal transmission and reception to detect the level of water/liquid.

Radar sensor PCBA is resistant to temperature, pressure and dust. In addition to liquids, they can measure pastes, powders and solids. Additionally, they provide accurate water level measurements and require no calibration. Also, it doesn't have to touch the liquid it's sensing. Therefore, it is non-invasive.

Radar sensors are ideal for hot liquid storage tanks. However, like most continuous level measurement sensors, radar level sensors are expensive. Furthermore, they have a limited detection range. Therefore, we can also use them for hot asphalt tanks in tile manufacturing plants.

Submersible pressure sensor (transmitter)

Submersible pressure sensors measure the amount of water in a tank/area by evaluating the pressure in the tank/area. We usually place them at the bottom of our website. Since we use these sensors in harsh environments, they must be subjected to excessive stress. Therefore, they must be composed of sturdy materials.

We use this water level gauge as a reference gauge along with other level sensor PCBAs, mainly when we use them for surface water applications.

water level sensor module

water level sensor level module

We mainly use liquid water level sensors in commercial and industrial applications. However, some are available for education and hobbyists. The water level sensor module is one such sensor.

Water level sensor PCBA modules are usually small conductive level sensors. They mainly use variable resistors to determine the amount of water in the container. They can also detect the size of water droplets/droplets within an area/system. Therefore, they can be used to see precipitation or moisture in the air.

They are compatible with the most popular microcontrollers and single-board computers such as Raspberry Pi and Arduino Uno. The body of the sensor consists of ten exposed copper traces. Half are sense wires and the rest are power wires.

Some water level sensor modules have a power LED to indicate the current flowing through the module.

Connect the water level sensor module with the Arduino

Water level sensor module vector image

Source: FreeSVG

The water level sensor module has a simple structure. It usually consists of three pins:

Signal (S): An analog pin that sends a signal to the microcontroller/SBC to indicate the liquid level.

VCC/5V (+): Power input pin. It accepts 3.3V to 5V input.

GND (-): Indicates ground.

We can use these pins to connect the liquid level sensor with the Arduino.

Water Level Sensor PCBA Model and Arduino Project Tutorial

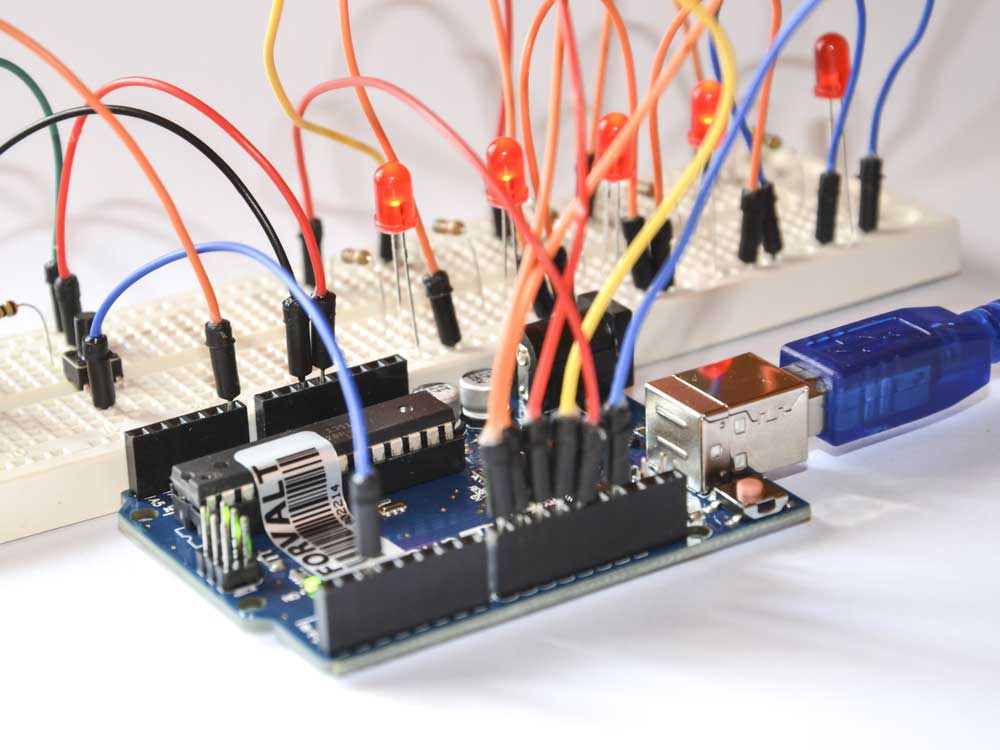

Arduino Uno connected to breadboard

The Arduino Uno is connected to the breadboard.

The following tutorial will show you how to connect the liquid level sensor module to Arduino and display the water depth on the LCD screen. The LCD character display will act as our level indicator.

Tutorial Parts List

This project requires some components. They include:

Arduino Uno (or any other compatible microcontroller)

Arduino Super 2560

Water level sensor module (or leak detection sensor)

Breadboard and Wire Kit

LCD character display

10K potentiometer

Tutorial steps

Arduino Uno next to the display module

Connect the PCBA ground pin of the water level sensor to the ground pin on the Arduino. *Note: Alternatively, you can connect or route the connection through the ground pin on the breadboard

Connect VCC to the 5V rail on the Arduino (or breadboard)

Connect the signal pin to any analog input pin on the Arduino - we recommend using the A5 pin

Run the Arduino IDE on your computer, copy and flash the following sketch to the Arduino

NOTE: Alternatively, you can use this sketch to print the output of the water sensor to the console

Before performing the above steps (if applicable), please make sure that you have properly connected the LCD character display. If you want to learn more about LCD character displays, you can visit our article on i2c adapters and protocols. In addition, we provide useful guides on LCD interfaces.

Everyone's water is different and contains inconsistent impurities and chemicals. Therefore, you will need to adjust the code and calibrate the water level sensor to ensure that it returns an accurate reading of the current water level. However, once you've assembled your project, you can start calibrating it by testing it in a glass of water and changing some variables in the code.

There are many practical uses for this project. For example, you can detect a water heater leak by searching for moisture in the drain pan.

However, once you have properly calibrated the water sensor, you should see the water depth on the LCD screen or console.

Water heater with gas safety valve

You can also use it in a vacant holiday home to assess the amount of water near the toilet or under the sink.

in conclusion

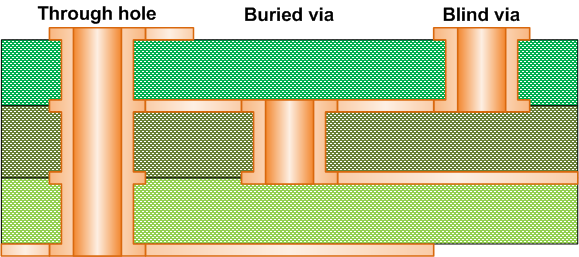

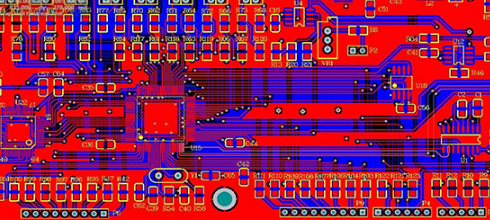

There are many types of water level sensing technologies. Their applications can often overlap. Therefore, when choosing a water level sensor PCBA, you must determine the purpose of the measurement. Also, it helps to determine the temperature of the liquid you will be measuring. As the above text proves, you don't have to buy a commercial water level sensor. Using an inexpensive Arduino microcontroller paired with a water sensor module, you can create one of your own. You can visit our circuit board PCB guide to learn more.

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: