address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

Difference Between FR-4 Material and Rogers Material

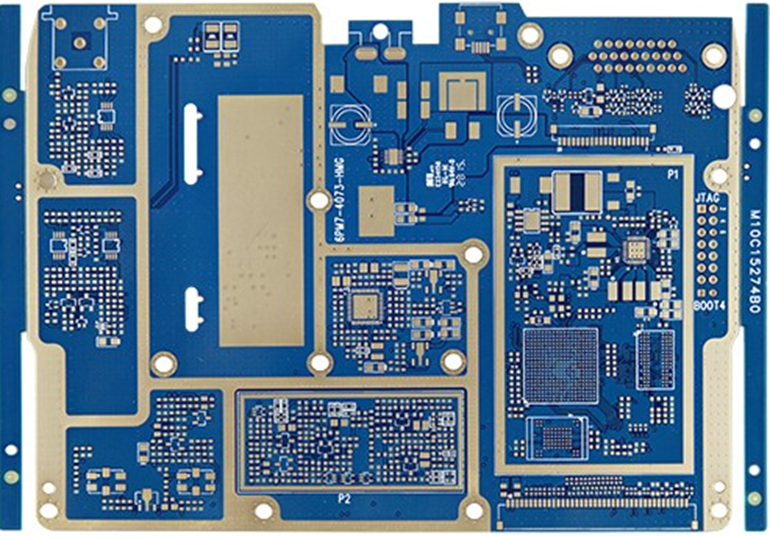

What is the FR-4 material?

The FR-4 material for PCB manufacturing is made from woven fiberglass cloth in combination with an epoxy rose that binds these together and also brings flame resistance. The FR in FR-4 material stands for fire retardant, and instead of being material, it is a grade of material that denotes material compliance with the UL94V-0 standard.

FR-4 material is known for its good weight-to-strength ratio as it is a versatile thermoset plastic laminate with a high-pressure grade. This material is usually used as a good electrical insulator with good mechanical strength. Good manufacturing characteristics make it a reliable choice for different mechanical and electrical appliances under different environmental circumstances.

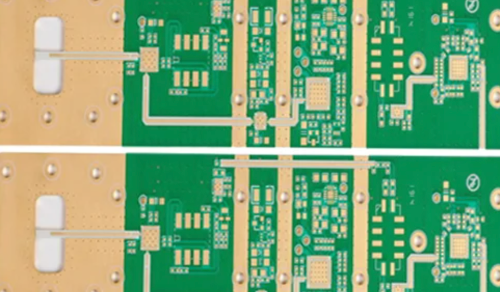

What is the Rogers material?

Roger itself is a PCB manufacturing and laminating material manufacturer. So, the PCB material you will get here will also be FR-4, meaning that it is a flame retardant of level 4 made with epoxy and fiberglass. However, the PCB made with Rogers material will have copper laminate with reliable core materials like Teflon(PTFE). Thus, these come with better high-frequency application properties. These features also make a good choice for a specific set of applications.

Difference Between FR-4 Material and Rogers Material

While these materials seem pretty similar, there is a huge difference between FR-4 material and Rogers material. So, read on to know what brings the difference between FR-4 material and Rogers material and which one will be a better choice for you.

Pricing

The first important difference between FR-4 material and Rogers material is their price. When manufacturing a PCB, it is essential to maintain affordability but sometimes, maintaining quality and specifications increases the process.

The same is the case with the FR-4 material and the Rogers material. When we compare the costs of both these PCB materials, the findings are that FR-4 is cheaper and offers more low-cost PCB manufacturing than Rogers material.

The low manufacturing price is also why it is being vastly used across the industry. So, if you want your product with a low-cost PCB, then FR-4 is the better choice. However, it may bring some quality limitations, and you must go for Rogers material for better quality.

High-Frequency

Another reason these two PCB materials are so popular is their frequency ranges. There are different electrical applications where different frequency ranges are necessary, and both of these materials are suitable for the respective requirements. However, the material difference and end-user performance differ in the frequency of these two materials.

FR-4 is famous for its low cost, but it does not make it the better option when you need it for some high-frequency applications. At the same time, Rogers material makes a better option for high-frequency applications with its better materials. The PCB material selection depends on your preferences, but if you want the high-frequency application, Rogers material is a better pick.

Impedance stability

Impedance is the measure of resistance against the flow of electric current whenever some voltage is applied to the circuit. It depends on the material you use for your circuit, and impedance stability is necessary depending on the circuit's application. When comparing things for these two materials, it is found that FR-4 material is highly vulnerable to variations in the dielectric constant of your circuit whenever there is a change in the temperature.

On the other hand, Rogers material shows better impedance stability in different temperature conditions. It comes with lease variations across the substrate resulting in better stability.

Temperature management

Most high-performance electronics heat up when they are used to their fullest. The heat is mainly generated from the PCB, and the PCB that is not good with temperature management lowers its performance. The temperature differences in the environment can also affect the performance of your PCB, but it mainly depends on the material used.

The FR-4 material has higher performance variations when the temperature varies. So, it is not that good in terms of temperature management. However, Rogers material is good in temperature management with the least performance variations across different temperature conditions. For a high-performance appliance, it is necessary to maintain its performance no matter what the circumstances are.

Dissipation factor

The dissipation factor is yet another important quality that PCBs must have today. It is essential to hold current through the circuit for the least signal loss. However, it may not be very important for all applications because different circuits come with tolerance depending on the circuit design. So, FR-4 material comes with a higher dissipation factor, while the Rogers material has a lesser dissipation factor.

It means that the tendency of Rogers material to hold signals is better than that of FR-4, but it is only necessary for a few applications.

Dielectric constant

The ability of a material to store electrical energy in the form of electrical fields is known as its dielectric constant. Different materials come with different dielectric constants. For a better-performing circuit design, PCBs need a material that provides a stable dielectric constant value over a wide range of values. The dielectric constant can affect the results the circuit on your PCB provides.

The dielectric constant is very important for high-frequency applications, and Rogers material comes with a stable dielectric constant value for a wider range. It works better in different high-frequency environments with the least chance of dielectric loss, providing a much more stable PCB output than FR-4.

Moisture absorption

Different materials of a PCB come with different moisture absorption qualities. The materials that tend to absorb moisture easily must not be used in harsh conditions that change and the moisture exposure to your PCB can increase. Similarly, selecting the PCB material is important here as the right type of material will not have many issues.

As the Rogers material for PCB offers overall higher quality, it is also better in terms of moisture absorption. Rogers material is much better in terms of absorbing moisture as it comes with a low absorption rate. Comparing it with FR-4, you will get a higher moisture absorption rate here, making it inefficient.

Space application

Today most developed countries are working on space travel, and companies across the globe are investing in this technology. PCB also makes the brains of all the equipment used for space travel and exploration. However, the PCB used for such things must provide perfect values regardless of the circumstances. PCB material is vital in space applications with excellent functionality and performance requirements.

Here FR-4 material will be a good choice for manufacturability, electrical stability, durability, and low cost. On the other hand, the Rogers material will be a better choice because of its low outgassing qualities. Thus, it is a more favorable option considering space exploration and usage under different conditions.

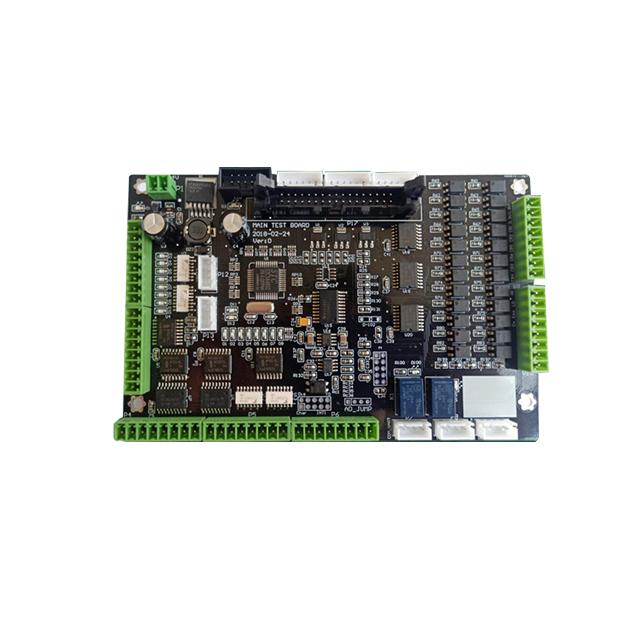

Which of these makes a better choice and for which applications?

Now that you have seen the quality and functionality difference between FR-4 material and Rogers material, you must know which one makes a better choice for which applications. At a glance, Rogers material is a much better option considering it scores a point for most of the differences.

The pricing factor is the only thing where it is beaten, but the higher manufacturing quality makes up for that. The following are some applications of the rogers material for PCB manufacturing.

Consumer electronics

Telecommunications

Aerospace

Military applications

However, if you are not looking for highly efficient electrical values and performance and cost-cutting is your main goal, then FR-4 will also make a good choice. There might be a slight compromise on the quality, but it will still deliver a good experience for the use case.

PCB holds an important role in all the electronics that we use today. Similarly, the material used for PCB manufacturing plays an important role in making that PCB more efficient in different circumstances. The most commonly used materials for manufacturing PCB were FR-4 and Rogers, and we hope that you know all the difference between FR-4 material and Rogers material now.

Conclusion:

Remember that selecting the right material according to your requirements is necessary. Otherwise, you may be unable to use the PCB to its fullest potential. At a glance, Rogers materials make a good choice for high-performance demanding applications. At the same time, FR-4 is a better option when you are on a tighter budget and want to fulfill a low-frequency application.

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: