address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

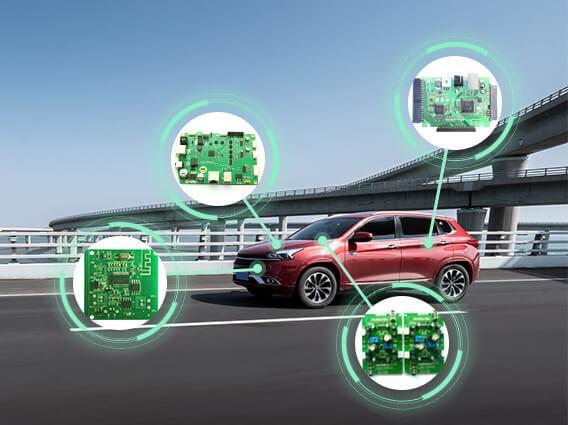

Automotive pcb assembly introduce

Automotive PCB assembly refers to the process of assembling printed circuit boards (PCBs) for automotive electronic systems. Automotive PCBs are an essential part of modern vehicles, providing critical functions such as engine control, safety systems, infotainment and connectivity. In this article, we discuss the requirements for automotive PCB assembly, the manufacturing process, and future trends in the industry.

two. Automotive PCB assembly requirements:

Durability and reliability: Automotive PCBs must be able to withstand harsh environmental conditions such as extreme temperatures, moisture and dust. They must also be resistant to corrosion, chemical attack and mechanical stress to ensure long-term reliability.

Temperature resistance: Automotive PCBs must operate over a wide temperature range, from sub-zero conditions to extreme heat. Therefore, the materials used for their construction must have excellent thermal stability, and the assembly process must ensure consistent performance under different temperature conditions.

Vibration and shock resistance: Automotive PCBs must resist vibration and shock, which can be caused by vehicle movement, rough roads, or collisions. The assembly process must use shock-absorbing materials, secure component mounting, and proper reinforcement to minimize the risk of damage or failure.

EMC and EMI Compatibility: Automotive PCBs must comply with electromagnetic compatibility (EMC) and electromagnetic interference (EMI) regulations to prevent interference with other electronic systems in the vehicle. The assembly process must use shielding, filtering and grounding techniques to minimize electromagnetic emissions and susceptibility.

3. Automotive PCB assembly manufacturing process:

Design and Prototyping: The first step in automotive PCB assembly is to design the circuit and layout of the PCB using specialized software tools. Prototyping involves creating a working model of a PCB to test its functionality and identify any design flaws.

Component Selection and Sourcing: Once the PCB design is complete, the next step is to select the appropriate components such as resistors, capacitors, diodes and integrated circuits. These components must meet performance, reliability and availability requirements.

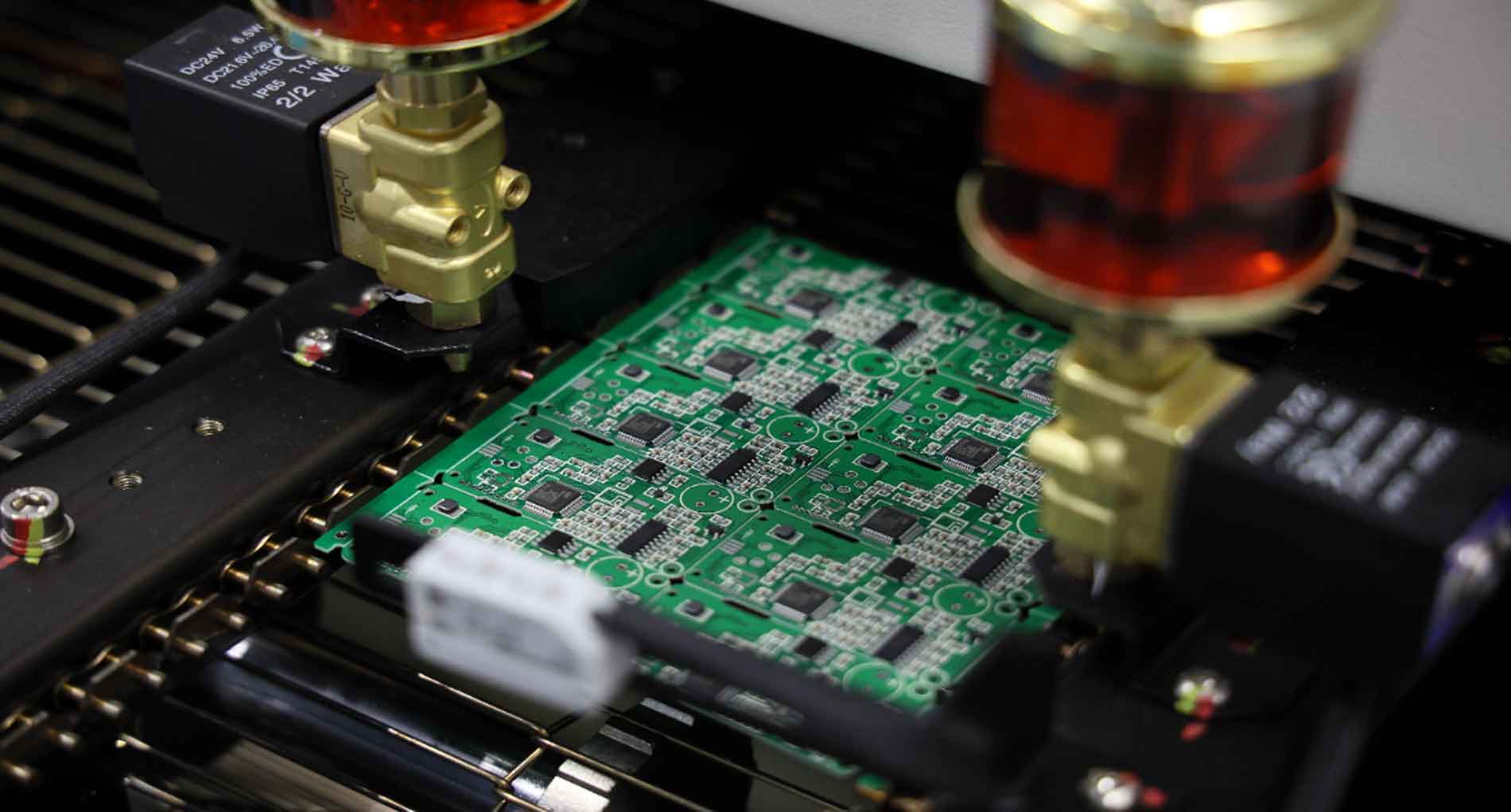

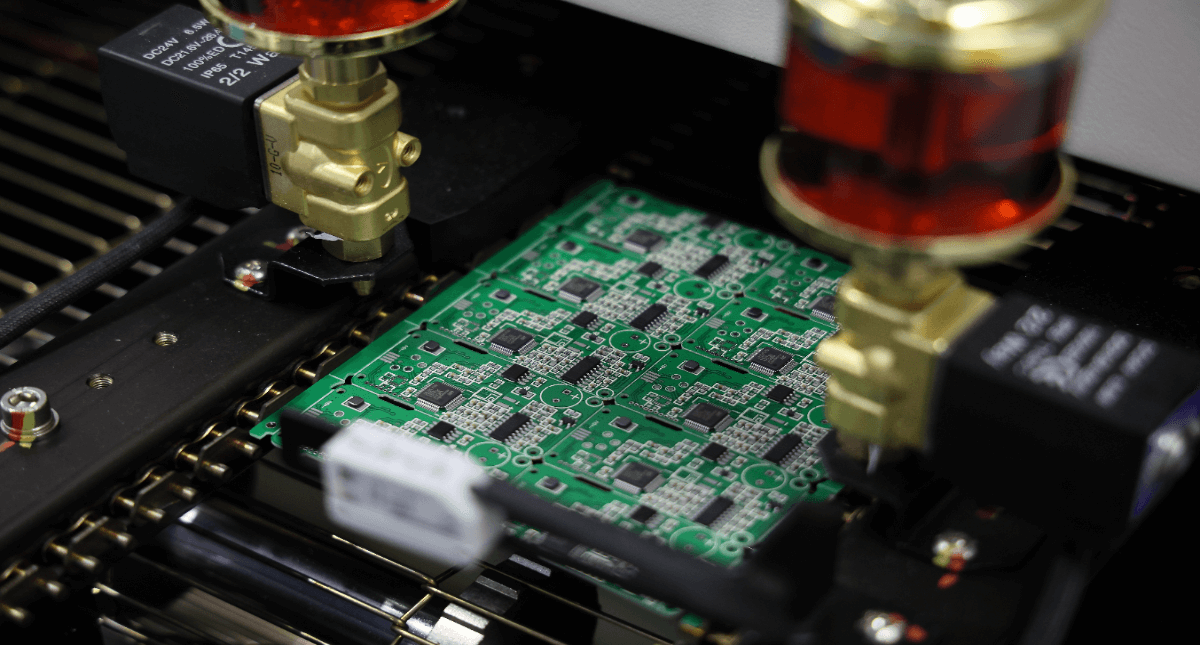

Surface Mount Technology (SMT) Assembly: SMT is the primary method used to assemble automotive PCBs, where components are mounted directly on the surface of the PCB. The SMT process involves applying solder paste to a PCB, placing components on top of the paste, and then heating the PCB to melt the solder and create a permanent connection.

Through-hole assembly: Through-hole assembly is another method used to mount components on a PCB, where the component is inserted through a hole in the PCB and soldered on the other side. This method is used for larger or heavier parts that require greater mechanical stability.

Testing and Quality Control: Once a PCB is assembled, it undergoes rigorous testing to ensure it meets requirements for functionality, durability, and reliability. Quality control involves visual inspection, electrical testing and functional testing to identify any defects or performance issues.

4. The future trend of automotive PCB assembly:

Advanced materials and technologies: use of advanced materials such as ceramics, composites and nanomaterials

The automotive PCB assembly industry is expected to see an increase in materials. These materials provide better thermal stability, mechanical strength and electrical performance, enabling more durable and reliable PCBs. In addition, emerging technologies such as 5G, autonomous driving and electric vehicles are expected to require more advanced PCBs to support their functions.

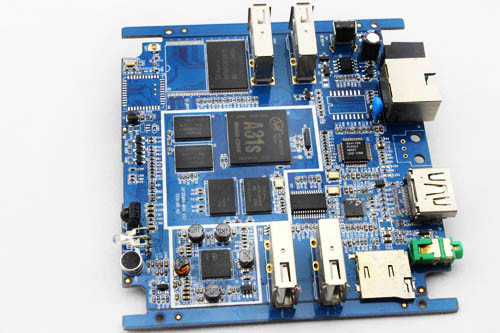

Increased integration and miniaturization: With the trend of electronic systems becoming more compact and efficient, the demand for smaller and more integrated PCBs is growing. Automotive PCB assembly is expected to adopt advanced packaging technologies such as system-on-chip (SoC) and system-in-package (SiP) to create more compact and efficient PCB designs.

Artificial Intelligence and Machine Learning: The use of artificial intelligence (AI) and machine learning (ML) is expected to increase in the automotive industry, including in PCB assembly. AI and ML can help optimize PCB designs, improve production efficiency, and enhance quality control by detecting defects and predicting failures before they occur.

Sustainability and Environmental Considerations: The automotive industry is increasingly focusing on sustainability and environmental issues. The PCB assembly process is expected to use more environmentally friendly materials and processes, such as lead-free solder and recycling of e-waste. In addition, the use of renewable energy sources such as solar and wind power,

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: