address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

China PCB Assembly Manufacturers Revolutionizing World

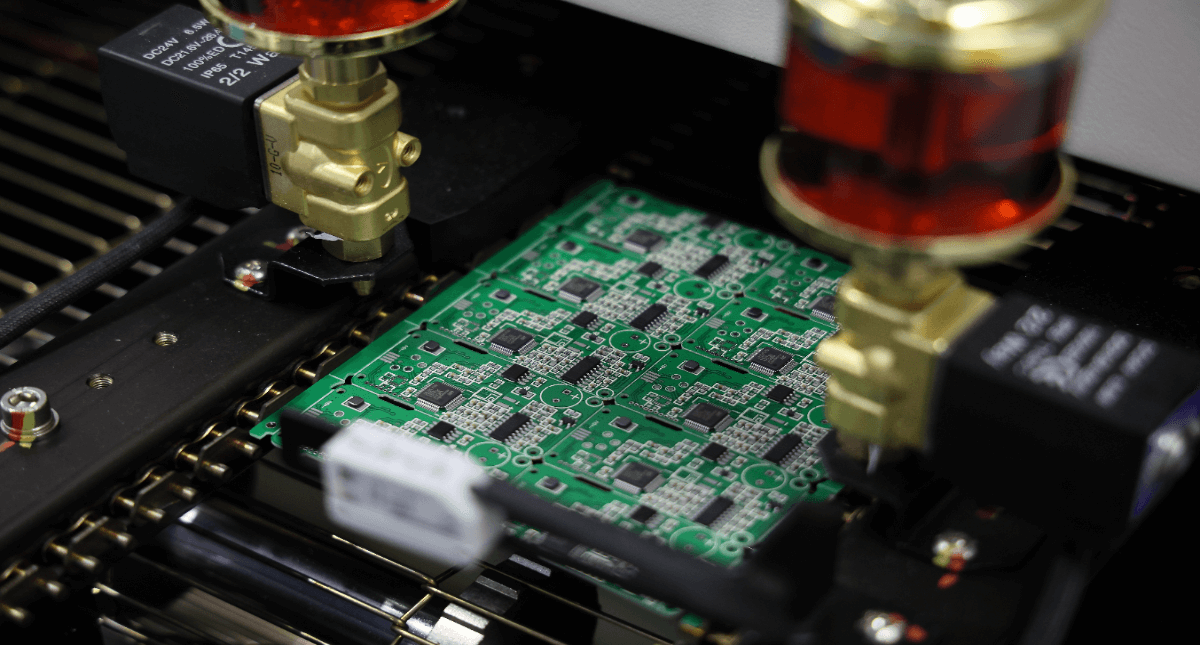

In the world of technology, circuit boards are the backbone for innovation and development. And when it comes to reliable and high-quality circuit board assembly, China is leading the way. With the increase in demand for electronic devices and equipment, China circuit board assembly manufacturers have taken the initiative to revolutionize the electronics industry. They are providing top-notch PCBA at the best price for various industries and uses around the world. In this blog, we will explore the power and impact of quality circuit board assembly and how Chinese manufacturers are taking the industry by storm.

Section 1

Section 1: The Importance of Quality Circuit Board Assembly

Circuit boards, commonly referred to as printed circuit boards (PCBs), are essential components of many electronic devices. They provide connectivity and support to electronic components, allowing them to communicate with each other and work together effectively. The quality of PCB assembly can directly impact the performance, reliability, and lifespan of an electronic device.

Using poor-quality circuit board assembly can lead to a host of problems. For instance, defective circuit boards can cause hardware failure, disruptions in communication, and unexpected shutdowns. These issues ultimately result in costly repairs, recalls, and damage to a company's reputation.

On the other hand, investing in high-quality PCB assembly pays off in the form of increased reliability, functionality, and efficiency. Quality PCBs can improve the overall performance of electronic devices and reduce the likelihood of costly repairs or replacements. As such, investing in quality circuit board assembly is crucial for companies that rely on electronic devices to run their operations smoothly.

Section 2: How China Circuit Board Assembly Manufacturers are Changing the Game

The electronics industry is highly competitive, and Chinese PCB manufacturers have been making great strides in recent years. China is the world's largest PCB producer, with a market share of over 40%. Their dominance in the market is attributed to several advantages over their competitors.

Firstly, working with Chinese PCB manufacturers can significantly reduce production costs. China's lower labor costs, raw material pricing, and access to advanced manufacturing technology make it possible for them to offer highly competitive pricing on their PCBA services.

Secondly, Chinese PCB manufacturers have a reputation for producing high-quality circuit boards, which meet international standards. They have made significant investments in research, development, and training programs to enhance their manufacturing processes and ensure consistent quality control.

Finally, Chinese PCB manufacturers offer customization capabilities, which allow businesses to tailor their PCBA to meet unique design requirements. They have a vast pool of engineering talent and state-of-the-art equipment, making it possible to execute even the most complex projects.

Some of the top Chinese PCB manufacturers include Shenzhen JieHe Technology Development Ltd, Shenzhen Hengda Electronics, and Shenzhen Ruiyan Communication Equipment Co., Ltd. These companies have demonstrated their ability to produce high-quality, cost-effective PCBAs.

In conclusion, Chinese PCB manufacturers have undoubtedly changed the electronics industry's game by offering high-quality, cost-effective custom circuit board assembly solutions. As businesses continue to innovate and develop new products, Chinese PCB manufacturers will undoubtedly play a vital role in providing the PCBAs they need to succeed.

Section 3: The Advantages of PCBAs from China

In recent years, China has become a major force in the PCB industry. Chinese circuit board manufacturers are known for producing top-quality PCBAs at a competitive price. Here are some of the advantages of working with China circuit board assembly manufacturers:

Competitive pricing: One of the biggest advantages of working with Chinese PCB manufacturers is cost savings. Due to a vast network of suppliers and low labor costs, Chinese manufacturers are able to offer PCBAs at a lower price compared to other countries without compromising on quality.

High-quality materials and manufacturing processes: Chinese manufacturers are known for using high-quality materials and advanced manufacturing processes. They invest in state-of-the-art equipment, software, and techniques to deliver reliable and durable PCBAs that meet industry standards.

Customization options: Many Chinese PCB manufacturers offer customization services to suit specific project requirements. They can produce PCBAs in different sizes, shapes, and materials, and can work with customers to design products that meet their exact specifications.

In a competitive industry where innovation is key, Chinese PCB manufacturers are leading the way with their dynamic and affordable PCBA solutions. Businesses looking to capitalize on cost savings, high quality, and customization should consider working with Chinese PCB manufacturers.

Section 4: Best Practices for Working with Chinese PCB Manufacturers

When it comes to working with Chinese PCB manufacturers, it's essential to follow some best practices to ensure a successful partnership. Here are some tips to keep in mind:

1. Research and choose the right manufacturer: Before selecting a manufacturer, conduct thorough research. Check their reputation, reviews, and certifications to ensure they are reliable and can meet your quality standards. It's also essential to assess their capabilities and experience in your industry.

2. Effective communication: Language barriers can be a challenge when working with Chinese manufacturers. Hence, it's important to establish clear communication channels and ensure that you are on the same page at all times.

3. Quality assurance and inspection: Before shipping, conduct quality checks to ensure that the products are up to your specifications. Performing on-site inspections and audits can help identify issues before they become critical.

By following these best practices, you can build a strong and successful partnership with your chosen Chinese PCB manufacturer. With their expertise and your specifications, you can develop and deploy high-quality PCBAs to drive innovation and revolutionize the technology industry.

Section 2

Section 1: The Future of Circuit Board Assembly

The technology industry is constantly evolving, and circuit board assembly plays a crucial role in the development of new devices and innovations. As we look towards the future, it is clear that PCBAs will continue to be a driving force in emerging technologies. From the Internet of Things to autonomous vehicles, circuit boards are essential components in many cutting-edge products.

The potential for growth and innovation in the industry is vast, and PCBAs from China are expected to play a crucial role in shaping the future of technology. With their high-quality manufacturing processes, competitive pricing, and customization options, Chinese PCB manufacturers will be at the forefront of innovation in the industry.

As new technologies continue to emerge, there will be a growing demand for high-quality PCBAs that can provide reliable and consistent performance. Chinese manufacturers are well-positioned to meet this demand and drive the industry forward.

In conclusion, the future of circuit board assembly is bright, and Chinese manufacturers are at the forefront of this evolving industry. As technology continues to advance, it is essential to work with reliable and reputable manufacturers, and China circuit board assembly manufacturers are the best choice for providing high-quality PCBAs to drive innovation and success in the technology industry.

Section 2: The Future of Circuit Board Assembly

The future of circuit board assembly is exciting and full of potential. As technology continues to advance and new devices and equipment are developed, the demand for high-quality circuit boards will only increase. PCBAs will continue to play a crucial role in emerging technologies like AI, IoT, and 5G, making quality and reliability more important than ever.

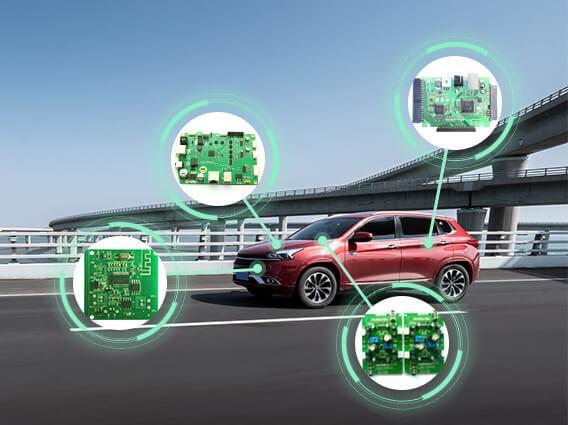

The potential impact of new innovations in the industry is vast. For example, the rise of autonomous vehicles will require advanced circuit boards to power the sensors and communication systems that make self-driving cars possible. And as the demand for renewable energy grows, circuit board assembly will be essential for developing more efficient and sustainable power generation systems.

Chinese manufacturers are well-positioned to continue driving innovation in the circuit board assembly industry. With their focus on quality and competitive pricing, they have already made significant contributions to the industry. As the world looks to new and exciting possibilities, Chinese manufacturers will play an essential role in bringing these innovations to life.

Section 3: Best Practices for Working with Chinese PCB Manufacturers

Working with Chinese PCB manufacturers can be a rewarding experience if done correctly. Here are some best practices to follow when working with Chinese manufacturers:

1. Tips for Choosing the Right Manufacturer:

When selecting a Chinese PCB manufacturer, it's crucial to ensure that they have the necessary certifications and quality standards. Look for manufacturers who have ISO or IATF certification, which shows that they meet international standards for quality management. Additionally, consider their reputation and experience in the industry.

2. Communication and Language Barriers:

A significant challenge when working with Chinese PCB manufacturers can be the language barrier. It's best to use clear and concise language in your communication and avoid industry jargon. Consider hiring a translator or using translation software to aid communication between your team and the manufacturer.

3. Quality Assurance and Inspection:

To ensure that you receive high-quality products, it's important to have a robust quality control and inspection process. Work with the Chinese PCB manufacturer to establish inspection criteria and conduct routine quality checks during the manufacturing process. Remember to provide feedback and address any issues promptly to avoid delays in production.

By following these best practices, you can ensure a successful working relationship with your Chinese PCB manufacturer and receive top-quality products.

Section 4: Best Practices for Working with Chinese PCB Manufacturers

When working with Chinese PCB manufacturers, there are a few best practices that you should keep in mind to ensure a successful partnership.

1. Tips for choosing the right manufacturer: With so many options available, it's essential to do your research and choose a manufacturer that can meet your specific needs. Look for a company with a proven track record of quality work, excellent customer service, and reasonable pricing.

2. Communication and language barriers: Communication and language barriers can pose a challenge when working with manufacturers in foreign countries. Be clear and concise in your communication, use simple language, and hire a translator if necessary to avoid misunderstandings.

3. Quality assurance and inspection: Quality assurance and inspection are critical when working with any manufacturer, but particularly when partnering with companies in foreign countries. Make sure to establish clear quality standards and perform regular inspections to ensure that your PCBAs meet your expectations.

With these best practices in mind, partnering with Chinese PCB manufacturers can be a rewarding and successful experience. By choosing the right manufacturer, communicating effectively, and prioritizing quality assurance, you can enjoy the benefits of high-quality PCBAs at a competitive price.

Section 3

Section 1: Best Practices for Working with Chinese PCB Manufacturers

Working with Chinese PCB manufacturers can be a highly cost-effective and efficient way to source high-quality PCBAs. However, it's important to have a solid business plan in place before engaging any suppliers. Here are some best practices to keep in mind when working with Chinese PCB manufacturers.

1. Choose the Right Manufacturer

Choosing the right manufacturer is crucial to the success of your project. It's important to research and evaluate potential suppliers based on criteria such as their reputation, experience, and certifications.

2. Communication and Language Barriers

The language barrier can be a challenge when working with Chinese manufacturers. It's important to develop clear communication channels and establish a common language with your supplier. In some cases, you may need to work with a third-party translator or interpreter.

3. Quality Assurance and Inspection

Quality assurance is critical to ensuring that your PCBAs meet your specifications and requirements. It's important to establish quality control metrics and work with your manufacturer to define inspection protocols and testing procedures.

4. Maintain Consistent and Open Communication

Effective communication is critical to the success of your project. Regularly communicating with your supplier will help to ensure that your project is on track and that any issues are quickly identified and addressed.

By following these best practices, you can establish an effective and successful partnership with your Chinese PCB manufacturer. With the right strategy and approach, you can drive innovation and success in the technology industry.

Section 2: The Future of Circuit Board Assembly

The demand for electronic devices and equipment is showing no signs of slowing down anytime soon, which means the need for high-quality PCBAs will only continue to rise. As emerging technologies such as artificial intelligence, augmented reality, and the Internet of Things become increasingly prevalent, the role of circuit board assembly will become even more critical.

PCBAs will play a crucial role in the development of these technologies, providing the backbone for new hardware and devices. China circuit board assembly manufacturers are well-positioned to help bring these innovations to life with their competitive pricing and high-quality materials and manufacturing processes.

As the world becomes increasingly interconnected, the global circuit board assembly industry will continue to evolve and adapt. With their extensive experience in the PCB market and constant innovation, Chinese manufacturers will be at the forefront of these changes, helping to shape the future of electronics. By choosing to work with Chinese manufacturers, businesses can ensure they remain at the forefront of technological advancements and maintain a competitive edge in their respective markets.

Section 3: The Future of Circuit Board Assembly

As technology continues to advance, the demand for smaller, more efficient, and highly integrated devices is on the rise. PCBAs are at the forefront of this technology surge, playing a crucial role in the development of emerging technologies such as 5G, IoT, and AI.

China PCB manufacturers are investing heavily in research and development to ensure they remain at the forefront of these technological advancements. With their vast knowledge base, expertise, and vast manufacturing capabilities, Chinese manufacturers are uniquely positioned to drive innovation in PCBAs that will shape the future of the electronics industry.

The next decade will see tremendous growth and innovation in PCBAs, from the development of highly integrated solutions, flexible circuits, and environmental sustainability initiatives. Chinese manufacturers, with their competitive pricing, quality workmanship, and customization capabilities, are well-positioned to take on this challenge and provide the necessary solutions to power the future of advanced technology.

Section 4: The Future of Circuit Board Assembly

The circuit board assembly industry has experienced immense growth in the past few years, and the future looks even brighter. With emerging technologies such as IoT, 5G, and AI, the demand for circuit board assembly is expected to increase globally. As these technologies continue to advance, circuit board assembly manufacturers will need to keep up with the pace and innovate accordingly.

One key area of growth for PCBAs is in the healthcare sector. With the rise of wearable technology and medical devices, there is a need for high-quality, reliable, and safe circuit board assemblies. Chinese manufacturers have already started exploring this market by developing advanced PCBAs for medical equipment and implants.

Another area of growth is in the automotive industry. As electric and autonomous vehicles become more popular, the demand for complex and advanced PCBAs will increase. Chinese manufacturers are already stepping up their game in this sector, with some leading companies partnering with global automotive firms.

Finally, PCBAs will continue to drive innovation in emerging technologies. From blockchain to renewable energy, circuit board assemblies will play a crucial role in developing cutting-edge solutions. Chinese manufacturers, with their competitive pricing and advanced manufacturing processes, will likely continue to be a driving force in the future of circuit board assembly.

Section 4

Section 1: The Future of Circuit Board Assembly

The world is changing rapidly, and so is the technology industry. Circuit board assembly has always been at the forefront of technology, and with the advent of artificial intelligence, the Internet of Things, and smart technology, the role of PCBAs has become even more critical. The future of circuit board assembly will see even more innovation, as the industry adapts to the demands of emerging technologies.

One significant trend in the industry is the move towards smaller and more compact circuit boards. With the need to make devices portable and easy to carry around, manufacturers are developing smaller and more efficient circuit boards to reduce device size without compromising their performance. This trend is driving innovation in the industry, as manufacturers develop new materials and manufacturing processes to make smaller and more powerful PCBAs.

Another trend is the increased use of automation in the manufacturing process. As demand for PCBAs continues to grow, manufacturers are investing in automated production lines to increase efficiency and reduce costs. This shift towards automation is creating new opportunities for innovation, as manufacturers incorporate artificial intelligence and other emerging technologies into their processes.

In conclusion, the future of circuit board assembly is full of possibilities. With advancements in technology driving innovation, the industry is poised to continue to grow and change. As Chinese PCB manufacturers continue to play a crucial role in the industry, the future looks bright for businesses looking to invest in high-quality PCBAs. By staying up-to-date with emerging technologies and working with the right manufacturers, businesses can stay ahead of the curve and lead the way in the technology industry.

Section 2: Best Practices for Working with Chinese PCB Manufacturers

When it comes to working with Chinese PCB manufacturers, it is crucial to follow best practices to ensure smooth communication, high-quality work, and timely delivery. Here are some tips for working effectively with Chinese PCB manufacturers:

1. Choose the Right Manufacturer: Do your research and choose a reliable and experienced PCB manufacturer with a proven track record of delivering quality work.

2. Communication and Language Barriers: Communication can be a challenge due to language barriers, cultural differences, and time zone differences. It is important to establish clear communication channels and use translation services or interpreters as needed.

3. Quality Assurance and Inspection: Verify that the manufacturer follows quality assurance and inspection protocols to ensure that the final product meets your specifications and requirements.

By following these best practices, you can build a successful partnership with Chinese PCB manufacturers and ensure that your PCBAs meet your expectations and drive innovation in the technology industry.

Section 3: The Future of Circuit Board Assembly

The world of technology is constantly evolving, and circuit board assembly is no exception. With the emergence of new technologies like 5G, artificial intelligence, and the Internet of Things (IoT), the need for advanced and efficient PCBAs is only going to increase.

One of the most exciting developments in the PCB industry is the use of flexible PCBs, which offer greater flexibility and durability than traditional rigid PCBs. This innovation is opening up new possibilities for wearables, medical devices, and other applications where flexibility is a must.

Moreover, the integration of smart technologies in PCBAs is becoming more prevalent. This includes the use of microcontrollers, sensors, and connectivity options like Wi-Fi and Bluetooth. PCBAs are becoming an integral part of smart homes, autonomous vehicles, and other emerging technologies.

As the demand for efficient and high-performance PCBAs continues to grow, Chinese manufacturers will undoubtedly play a vital role in meeting these needs. With their commitment to quality and innovation, they are poised to remain leaders in the PCB industry for years to come.

Section 4: Best Practices for Working with Chinese PCB Manufacturers

When it comes to choosing a PCB manufacturer in China, there are a few best practices to consider in order to ensure a successful partnership.

1. Research and choose the right manufacturer: Conduct a thorough search and comparison of different PCB manufacturers in China. Look for manufacturers with a good reputation and track record of delivering high-quality products. Reach out to them and ask for samples or references.

2. Communication and language barriers: It is important to establish clear lines of communication with your Chinese PCB manufacturer. Some manufacturers may have language barriers, so it is crucial to have a translator or interpreter to facilitate communication.

3. Quality assurance and inspection: Before finalizing the order, it is recommended to conduct an on-site inspection of the manufacturing facility to ensure that the manufacturer adheres to your quality assurance standards. Some manufacturers may even offer third-party inspection services to ensure quality.

By following these best practices, you can mitigate risks and ensure a reliable and successful partnership with your Chinese PCB manufacturer.

Section 5

Section 1: Best Practices for Working with Chinese PCB Manufacturers

Working with Chinese circuit board assembly manufacturers can be a game-changer for many businesses. However, to ensure success, it is essential to follow best practices. Here are some tips to help you navigate the process:

1. Tips for Choosing the Right Manufacturer: Do your research and choose a manufacturer with a solid reputation for quality and reliability. Look for reviews and testimonials from past customers, and verify their certifications and experience.

2. Communication and Language Barriers: Clear and effective communication is critical. Ensure that you have a point person who can communicate efficiently with the manufacturer. Consider using translation services or hiring a bilingual employee to bridge any communication gaps.

3. Quality Assurance and Inspection: Make sure your product meets quality standards. Defining adequate inspection criteria and requirements ensures that you receive quality products. It would be best if you also performed factory audits regularly to ensure that the manufacturer is staying up to the required standards.

Following these best practices can help you foster a reliable and collaborative relationship with your Chinese PCB manufacturer. This will translate into high-quality products, satisfied customers, and ultimately, a successful business.

Section 2: The Future of Circuit Board Assembly

The future of circuit board assembly is bright and full of promise. As technology continues to advance at an unprecedented rate, PCBAs will play an increasingly important role in powering and connecting the devices of our modern world. Some of the emerging technologies that will rely heavily on high-quality PCBAs include:

- Internet of Things (IoT): Devices connected to the internet will require reliable and robust circuit boards to function properly and communicate with each other.

- Artificial Intelligence (AI): The processing power and computing capabilities required for AI applications will rely heavily on high-quality PCBAs.

- Renewable Energy: The development and integration of solar, wind, and other sources of renewable energy will require advanced and efficient PCBAs for optimal performance.

As these emerging technologies continue to drive innovation in the technology industry, Chinese circuit board assembly manufacturers will continue to play a crucial role in supplying high-quality PCBAs at the best price. By partnering with these manufacturers, companies in various industries will be able to stay ahead of the curve and unlock new opportunities for growth and success.

Section 3: The Future of Circuit Board Assembly

The world we live in is constantly evolving, and technology is one of the driving factors behind it. Circuit board assembly technology is no exception to this trend. As new technologies emerge, the role of PCBAs continues to grow and evolve.

One example is the rise of the Internet of Things (IoT). With more and more devices being connected to the internet, PCBAs have become key components in the development of IoT devices. These devices require smaller and more intricate PCBAs that can handle a wide range of data and power requirements.

Another interesting development in PCBAs is the growing interest in flexible circuit boards. These boards are bendable and can be molded to fit a wide range of shapes and designs, which opens up numerous possibilities for innovative product designs.

China circuit board assembly manufacturers are expected to play a significant role in the future of PCBAs. With their specialization in customizations and competitive pricing, they can help businesses adapt to and take advantage of new trends in the industry.

As advancements continue to push the boundaries of what is possible with PCBAs, it is important for businesses to stay up to date on emerging technologies and adapt accordingly. The right PCBAs can help businesses stay competitive and take advantage of the latest innovations.

Section 4: The Future of Circuit Board Assembly

As technology continues to evolve, the demand for high-quality and reliable circuit board assembly is only going to increase. From medical devices to autonomous vehicles, circuit boards are essential components of various emerging technologies. The future of circuit board assembly is exciting, and Chinese manufacturers will undoubtedly play a vital role in moving the industry forward.

One of the most significant trends we see is the increased demand for smaller and more efficient circuit boards. With the rise of IoT devices and wearables, manufacturers are seeking ways to make PCBs smaller without sacrificing performance. Chinese manufacturers have proven to be leaders in this area, consistently producing small and intricate circuit boards with high precision and quality.

Another trend in the future of circuit board assembly is the need for flexibility and customization. Many industries require PCBAs tailored to their specific needs, and Chinese manufacturers have proven to be capable of delivering on such requirements. They offer a wide range of customization options to meet the unique needs of their clients without compromising on quality.

Lastly, the future of circuit board assembly will see a continued push for more environmentally friendly and sustainable practices. Chinese manufacturers have already started implementing eco-friendly processes, such as lead-free soldering, to reduce the environmental impact of their operations. Expect to see more such efforts from the industry as a whole in the coming years.

In conclusion, the future of circuit board assembly is promising, and Chinese manufacturers are at the forefront of innovation and excellence. As technology continues to evolve, industries must choose the right manufacturers to ensure they stay ahead of the curve and deliver the best solutions to their customers. Collaborating with Chinese manufacturers can help achieve that goal and drive success in the technology industry.

Conclusion

Section 1: The Advantages of PCBAs from China

China is a leading manufacturer of circuit boards, producing high-quality and reliable PCBAs that are revolutionizing the technology industry. Here are some of the advantages of choosing PCBAs from China:

Competitive pricing: China's large-scale production capabilities, advanced manufacturing technologies, and low labor costs allow them to provide competitive pricing for PCBAs. This makes them an ideal choice for companies looking to reduce their manufacturing costs and increase their profit margins.

High-quality materials and manufacturing processes: China's PCB manufacturers use state-of-the-art machinery and equipment to produce high-quality circuit boards. They also use premium materials that are durable, reliable, and can withstand extreme conditions.

Customization options: China's PCB manufacturers offer a wide range of customization options to suit the specific needs of their clients. They can produce PCBAs in various shapes, sizes, and complexities to meet the requirements of different industries and applications.

Working with Chinese PCB manufacturers can provide significant advantages for companies looking to improve the quality of their products, reduce costs, and increase their competitiveness in the market. However, it is crucial to choose the right manufacturer that can deliver high-quality products, reliable service, and on-time delivery. In the next section, we will provide some tips for choosing the right PCB manufacturer and ensuring the quality of the PCBAs.

Section 2: Best Practices for Working with Chinese PCB Manufacturers

Working with Chinese PCB manufacturers can be a game-changer for companies looking to invest in high-quality and cost-effective circuit board assembly. However, it's critical to choose the right manufacturer and establish clear communication and quality assurance procedures to ensure a successful partnership. Here are some best practices to keep in mind:

1. Choose the right manufacturer: When selecting a Chinese PCB manufacturer, consider factors such as their experience, track record, customer base, and certifications. Look for manufacturers that specialize in your specific industry or application to ensure they have the necessary expertise and capabilities.

2. Communication and language barriers: Effective communication is crucial when working with any manufacturer, especially when there are language barriers. Be sure to establish clear channels of communication and consider hiring a translator or working with a local agent to facilitate discussions and ensure that everyone is on the same page.

3. Quality assurance and inspection: Quality assurance should be a top priority when working with Chinese PCB manufacturers. Establish a clear quality control plan that outlines your expectations for product quality, delivery times, and pricing. Consider conducting regular inspections and audits to ensure that your products meet your specifications and quality standards.

By following these best practices, working with a Chinese PCB manufacturer can be a seamless and profitable experience that can help your business stay competitive in the fast-paced world of technology.

Section 3: Best Practices for Working with Chinese PCB Manufacturers

When working with Chinese PCB manufacturers, it is important to keep in mind certain best practices to ensure a successful partnership. Here are some tips to consider:

1. Do Your Research: Before choosing a manufacturer, conduct thorough research on their credibility, reputation, and track record. Read reviews and testimonials from previous clients, and check whether they have certifications for quality and safety standards.

2. Communication and Language Barriers: When working with Chinese PCB manufacturers, there may be language barriers that can cause misunderstandings. To ensure smooth communication, establish a clear and detailed project plan and specifications, and use visual aids such as diagrams and images. It is also helpful to appoint a bilingual project manager or interpreter to act as a liaison between you and the manufacturer.

3. Quality Assurance and Inspection: Quality control is crucial to the success of any PCB assembly project. Inspect the manufacturer's manufacturing processes and quality assurance procedures, and check the final products for any defects or issues. It is also recommended to conduct on-site inspections to ensure that the manufacturer adheres to quality and safety standards.

By implementing these best practices, you can ensure a successful partnership with your Chinese PCB manufacturer and achieve high-quality PCBAs for your products.

Section 4: Best Practices for Working with Chinese PCB Manufacturers

Choosing the right manufacturer for your PCBAs is crucial to ensure high-quality products and efficient production. Here are some best practices for working with Chinese PCB manufacturers:

1. Do your research: Before choosing a manufacturer, research their reputation, experience, and customer feedback. Look into their certifications, quality control measures, and manufacturing capabilities.

2. Communicate clearly: Language barriers can make communication challenging, so be sure to establish clear communication channels and provide detailed specifications and requirements for your PCBAs.

3. Visit the factory: If possible, visit the factory to inspect their facilities and manufacturing processes. This can help you ensure quality control and identify any potential issues.

4. Establish a quality assurance process: Develop a quality assurance process with the manufacturer to ensure all products meet your requirements and standards. This can include inspections, testing, and documentation.

By following these best practices, you can establish a successful partnership with a Chinese PCB manufacturer and ensure high-quality products for your business.

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: