address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

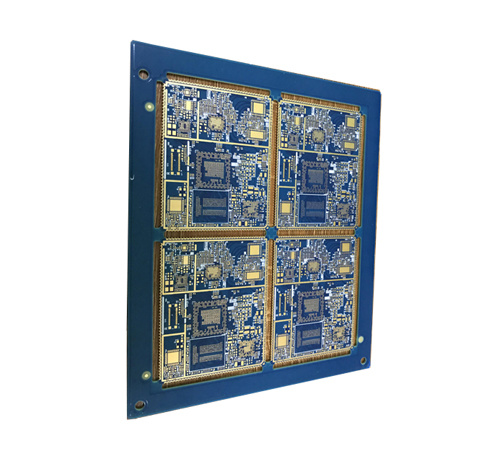

Uses And Characteristics Of Single-sided Circuit Boards And Multi-layer Circuit Boards

Uses and characteristics of single-sided circuit boards, double-sided circuit boards and multi-layer circuit boards.

Where are pcb multilayer circuit boards mostly used | PCB circuit board classification summary, introduces the use and characteristics of single-sided circuit boards, double-sided circuit boards, and multilayer circuit boards in detail.

PCB circuit board classification

According to the number of stacked layers, PCB circuit boards are divided into three major categories: single-sided circuit boards, double-sided circuit boards, and multi-layer circuit boards.

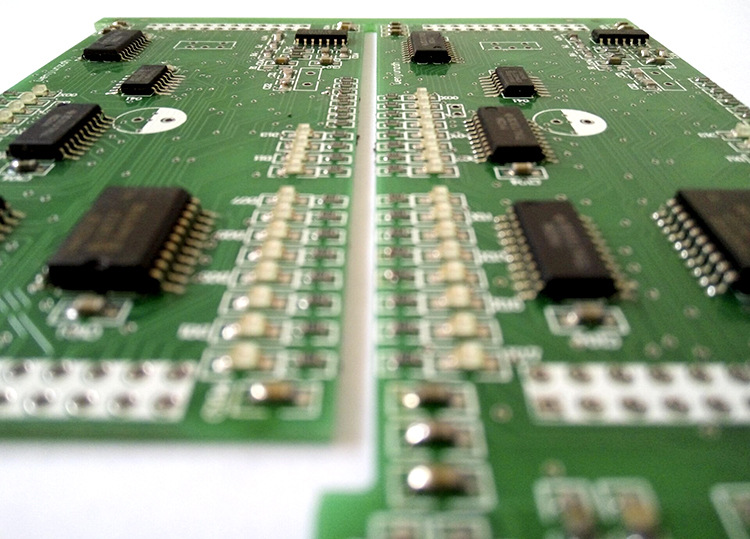

The first is a single-sided circuit. On the most basic PCB, parts are concentrated on one side, and power lines are concentrated on the other side. Since the power line only appears on one side, this type of PCB is called a single-sided circuit board. Single-sided circuit boards are generally easy to manufacture and low in construction cost, but the disadvantage is that they cannot be applied to too complicated products.

Double-sided circuit boards are an extension of single-sided circuit boards. When single-sided wiring cannot meet the needs of electronic equipment, double-sided circuit boards must be used. There are copper clad and wiring on both sides, and the line in the middle of the double layer can be switched on and off according to the pad, so that it can generate the necessary data connection.

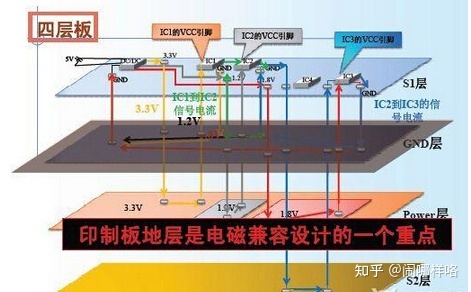

A multilayer circuit board refers to a pcb board that has more than three layers of conductive pattern layers and insulating layer materials laminated at intervals, and the conductive patterns of the period are interconnected as required. Multi-layer PCB circuit board is the material for the development trend of electronic device information technology towards high-speed operation, intelligence, large space, small volume, thin shape and light weight.

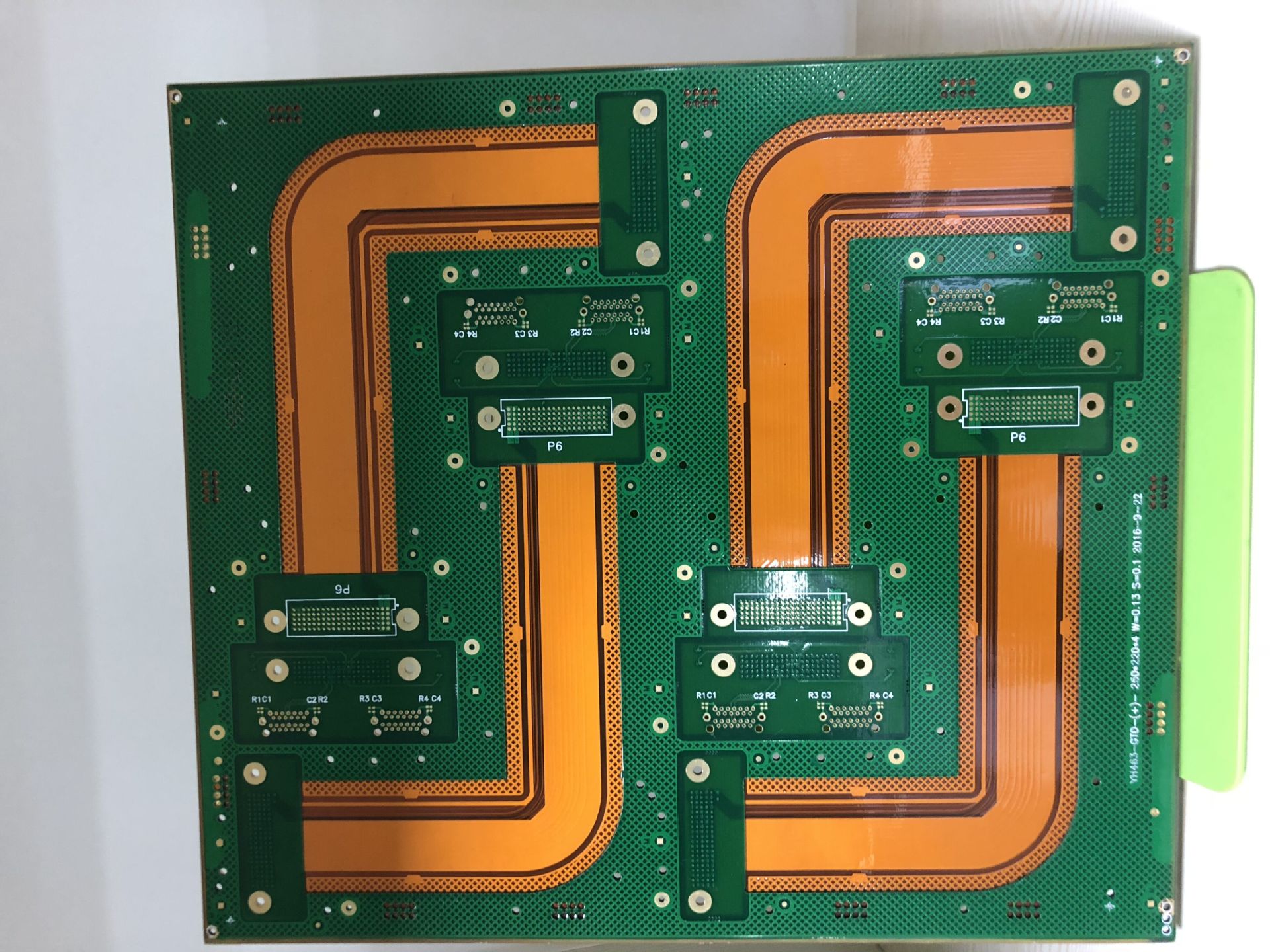

The pcb circuit board is divided into soft board (FPC), hard board (PCB), and soft-hard board (FPCB) according to its characteristics.

How to judge double-layer pcb circuit board and single-sided pcb circuit board

1. Take it up to the light, the inner core is not transparent, that is, it is all black, it is a multi-layer board, on the contrary it is a single-sided circuit board, and a single-sided circuit board has only one layer of wiring , there is no copper in the hole. The double-sided circuit board has lines on both sides, and there is copper in the guide hole.

2. The most fundamental difference is that the route stacking layers are different:

The single-sided pcb circuit board has only one layer of routing (copper layer), all holes are made of non-metallic materials, and there is no electroplating process step

The two-layer pcb circuit board has a double-layer route (copper layer), has metallized holes and non-metallic material holes, and has electroplating process steps

3. PCB circuit boards are divided into single-sided PCB circuit boards, double-sided PCB circuit boards and multi-layer PCB circuit boards. Multi-layer PCB circuit boards refer to PCB circuit boards with three layers and above. The processing technology of multi-layer PCB circuit board is based on the single-sided and double-sided circuit board plus the manufacturing process of internal pressure lamination. It can also be parsed out by using slicing.

Which products must use PCB boards

Electronic equipment that needs integrated routes. In order to save space, make products lighter/more durable/and achieve better performance, these electronic equipment must replace the previous power line connection and then change to the PCB circuit board . PCB is very good to meet the requirements of space/characteristics and reliability.

Not every home appliance needs circuit boards, simple home appliances may not need power circuits such as motors. However, household appliances with special functions generally require circuit boards to complete them, such as TVs, tape recorders, computers, and many others. There is also a PCB board at the bottom of the rice cooker, and a speed-regulating motor in the cooling fan.

Which types of products use PCB boards

PCB generally refers to hard circuit boards, which are used in desktop computer motherboards, computer mouse boards, independent graphics cards, office supplies, copiers, printers, remote controllers, various charging heads, computing methods, digital cameras, tape recorders, TV motherboards, Limited TV amplifiers, mobile phones, automatic washing machines, electronic scales, telephones, LED lamps, household appliances: central air conditioners, refrigerators, speakers, MP3; mechanical equipment, GPS, cars, instruments, medical equipment, aircraft Fields, military equipment, cruise missiles, communication satellites, etc. (There is also a kind of APCB. It is also a circuit board, but it is soft, and the circuit between the connection cover and the key of a flip phone uses a flexible circuit board).

The main board of the mobile phone and the functional keyboard are plastic bed boards; the connection line of the slide mobile phone or flip mobile phone is a flexible circuit board. The controller generally uses a carbon membrane plate. From top to bottom, the upper board of the mobile phone is a radio frequency circuit, a circuit, an audio power circuit, and a sequential logic circuit.

Generally, the electric kettle that is only heated does not have a circuit board, and the wire support frame is directly connected. Vertical drinking fountains also have circuit boards. Rice cookers generally have pcb circuit boards, induction cookers have pcb circuit boards, and electric fans have pcb circuit boards, but they generally play the roles of variable speed, timing execution, and display information, and have no specific function with the operation of electric fans.

What products use two-layer boards, and what products use multi-layer boards?

The key depends on the characteristics of the double-layer PCB design . Whether the two-layer board can be considered, such as anti-interference, wiring, and EMC requirements. The two-layer board can be completed, so there is no need for a multi-layer board.

Which is better, double-layer pcb circuit board or single-sided pcb circuit board

In life, multi-layer boards are the most used type of PCB circuit boards at this stage, so what are the application advantages of multi-layer PCB circuit boards:

Advantages of using multi-layer PCB circuit boards:

1. The relative density of installation is high, the size is small, and the quality is light, considering the requirements of miniaturization of electronic products;

2. Due to the high relative density of installation, the connection between various components (including electronic devices) reduces the double-layer PCB design , and the installation operation has high reliability;

3. Because the pattern is repeatable and consistent, it reduces the errors and omissions of wiring and installation, and saves the maintenance, adjustment and inspection time of machinery and equipment;

4. It can increase the number of superimposed layers of wiring, thereby increasing the coordination ability of design schemes;

5. It can form a power circuit with a certain characteristic impedance, and can generate a point-to-point transmission power circuit;

6. The shielding layer of the power circuit and equivalent circuit can be set, and the heat dissipation layer of the metal core can also be set to meet special function needs such as shielding and heat dissipation.

With the continuous development of electronic information technology and the continuous improvement of electronic product requirements in the computer, medical, aviation and other industries, the forward volume of the circuit board is reduced, the quality is improved, and the density is increased. Due to the limitation of available space, single-sided and double-sided PCB boards are no longer able to achieve a further increase in installation density. Therefore, it is necessary to consider the use of multi-layer PCB boards with higher stacking layers and higher assembly density. Multi-layer PCB circuit boards have been widely used in the production and processing of electronic devices due to their flexible design, stable and reliable electrical characteristics and good economical characteristics.

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: