address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

Which Is Better PCBA Electronic Patch Proofing

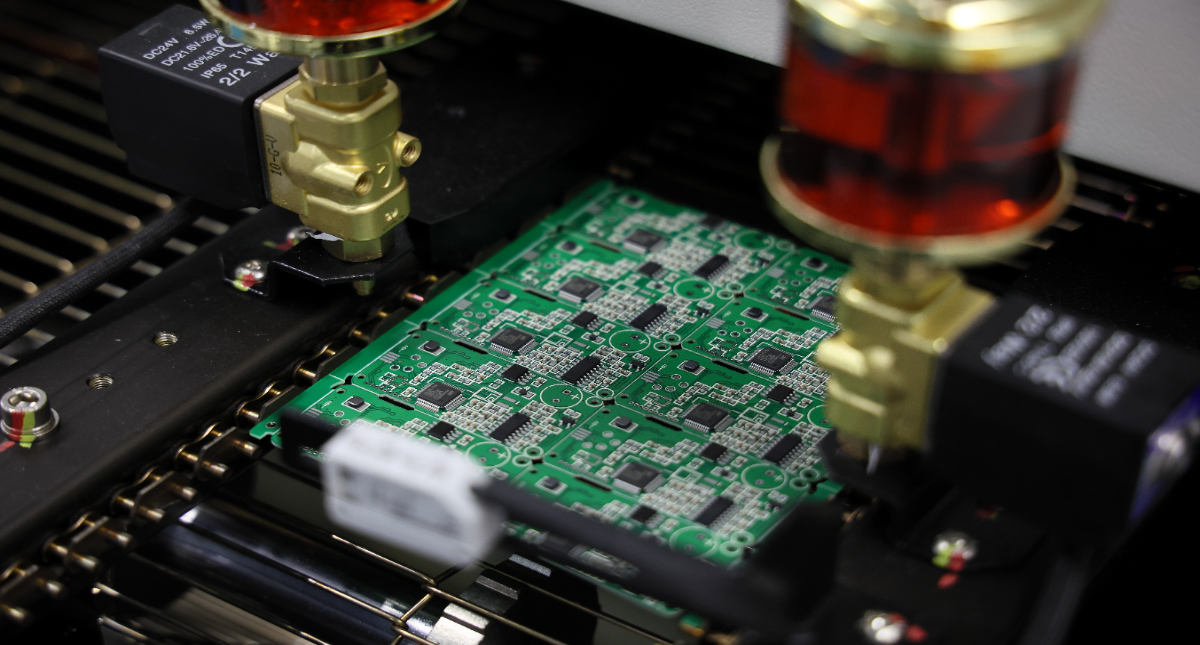

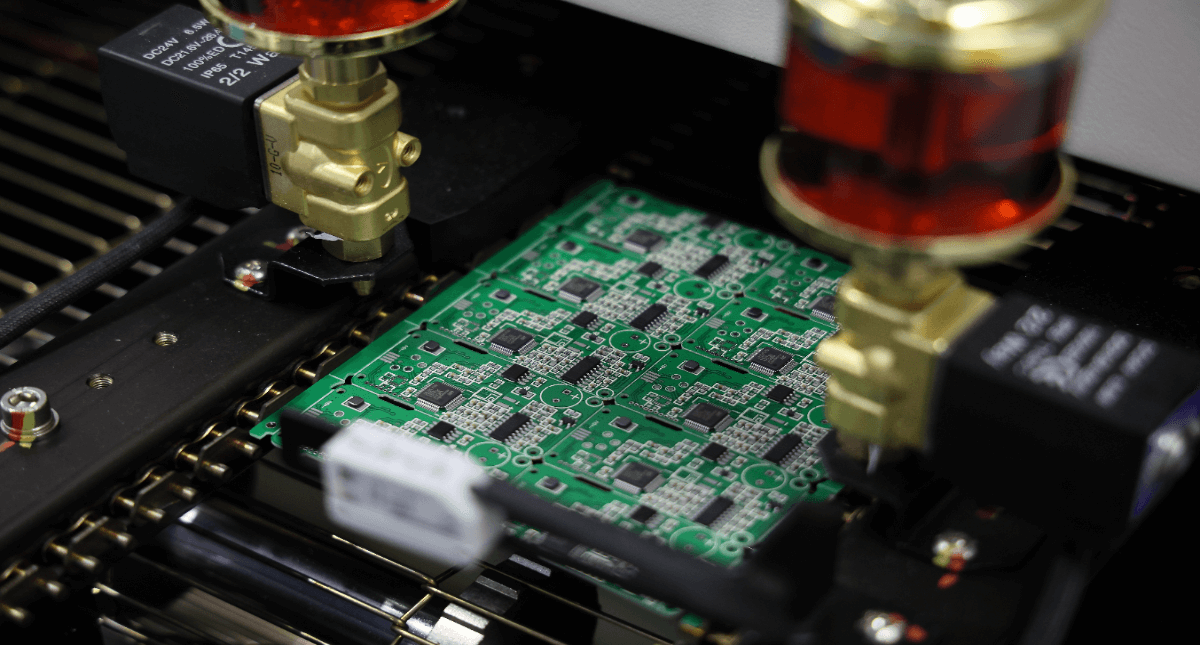

proofing means that due to the design of new products, a small batch of SMT patch processing trial production is required, so as to test the function of the product and the subsequent batch PCBA processing trial production verification process

Technology | SMT SMT processing | PCBA processing

Which is better PCBA electronic patch proofing

First, what is PCBA proofing

PCBA proofing means that due to the design of new products, a small batch < a href='https://www.kfpcpcba.net.cn/pcb-assembly-services/' target='_blank' > the trial production of SMT patch processing, so as to test the function of the product and the subsequent batch PCBA processing trial production verification process. After this link, it can be ensured that the design of the product meets the functional requirements and production needs, and generally speaking, the number of proofs is relatively small.

Second, which PCBA proofing is better

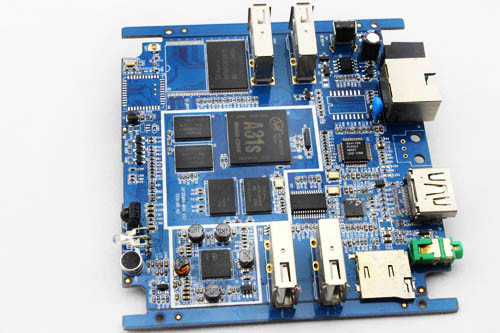

Founded in 2014 in Tianhe, Guangzhou, is mainly engaged in SMT proofing, PCB sample processing, BGA sample SMD welding, PCBA sample processing, engineering trial production sample patch, expedited circuit board SMD, manual patch proofing welding, small batch SMT patch processing and other sample welding business, its processing products cover the Internet of Things, medical, industrial control, communications, network, digital, security, transportation, smart home and many other industries.

Third, how is the quality of Pate electronic patch proofing

"Integrity-based, quality first, service-oriented, efficient and fast" as our company's slogan, we have been focusing on PCBA proofing and mass production services, working together to pursue more perfection to the extreme, and strive to do things well the first time. The current PCBA proofing pass-through rate of Pate Electronics is more than 95%, SMT patch rapid proofing, product production qualification rate is more than 99%, and customer satisfaction is more than 98%. When customers find placement problems caused by our company during product testing, our company promises to be fully responsible and unconditionally rework or bear the corresponding deduction; When there is no customer without special requirements, SMT patch rapid proofing, our company takes SJ/-1995 or IPC-610A as the inspection implementation standard;

Fourth, how about the delivery of Pate PCBA proofing

Our company undertakes the R & D sample 1 piece, without any engineering costs, start-up costs and geographical restrictions, normal delivery time 3 to 5 days, fast PCBA proofing only 24 hours, if the delivery date is delayed due to our company's reasons, each day postponed according to the total contract amount 5% from the processing fee deducted.

5. Standard SMT patch point calculation method

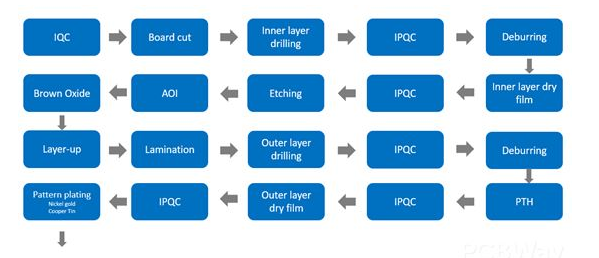

At present, the product processes of SMT patch mainly include: lead-free soldering process, lead soldering process and red glue soldering process. The method of calculating points is the same, only the price is different.

Sixth, why choose Pate Electronics as a PCBA proofing supplier

1. Our team can provide customers with the following packaged component patches: 0201, 0402, 0603, 0805, 1206, 1210, 1812, BGA, CSP, PLCC, LGA, QFN, QFP, TQFP, QFN, PLCC, SOT, SOIC, etc.;

2. Pate Electronics is a very responsible enterprise, and carefully does everything to ensure that the products attached will not appear in the wrong material, mixing, etc.;

3. We have strict quality control procedures, the welding straight-through rate is more than 96%, if welding defects are found, we promise to repair them free of charge;

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: