address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

The Art of PCBA Manufacturing: A Comprehensive Guide to Assembling PCBs

Assembling Printed Circuit Boards (PCBs) may seem like a daunting task, but it's a crucial step in the manufacturing process of electronic devices. A well-made PCB can enhance the overall performance and durability of the product, making it a critical component for manufacturers. With advancements in technology, PCBA manufacturing has become more complex and precise, calling for a deeper understanding of the process. In this comprehensive guide, we'll provide you with a detailed overview of what PCBA manufacturing is, the various stages involved in assembling a PCB, and tips for quality control to ensure the final product is of the highest standard. So, let's dive into the world of PCBA manufacturing and explore the art of assembling PCBs.

I. What is PCBA Manufacturing?

PCBA manufacturing refers to the process of assembling electronic components on a printed circuit board. The basic components of a PCB include the board, conductive traces, and electronic components.

II. PCBA Manufacturing Stages

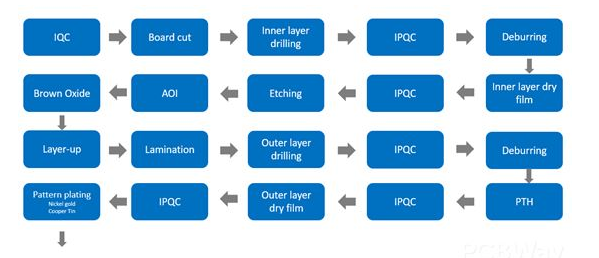

The PCBA manufacturing process involves several stages, including PCB design, PCB fabrication, component placement, soldering, testing, and inspection.

III. PCB Design

PCB design is the first step in PCBA manufacturing. It involves designing the circuit diagram and laying out the board using specialized software tools.

IV. PCB Fabrication

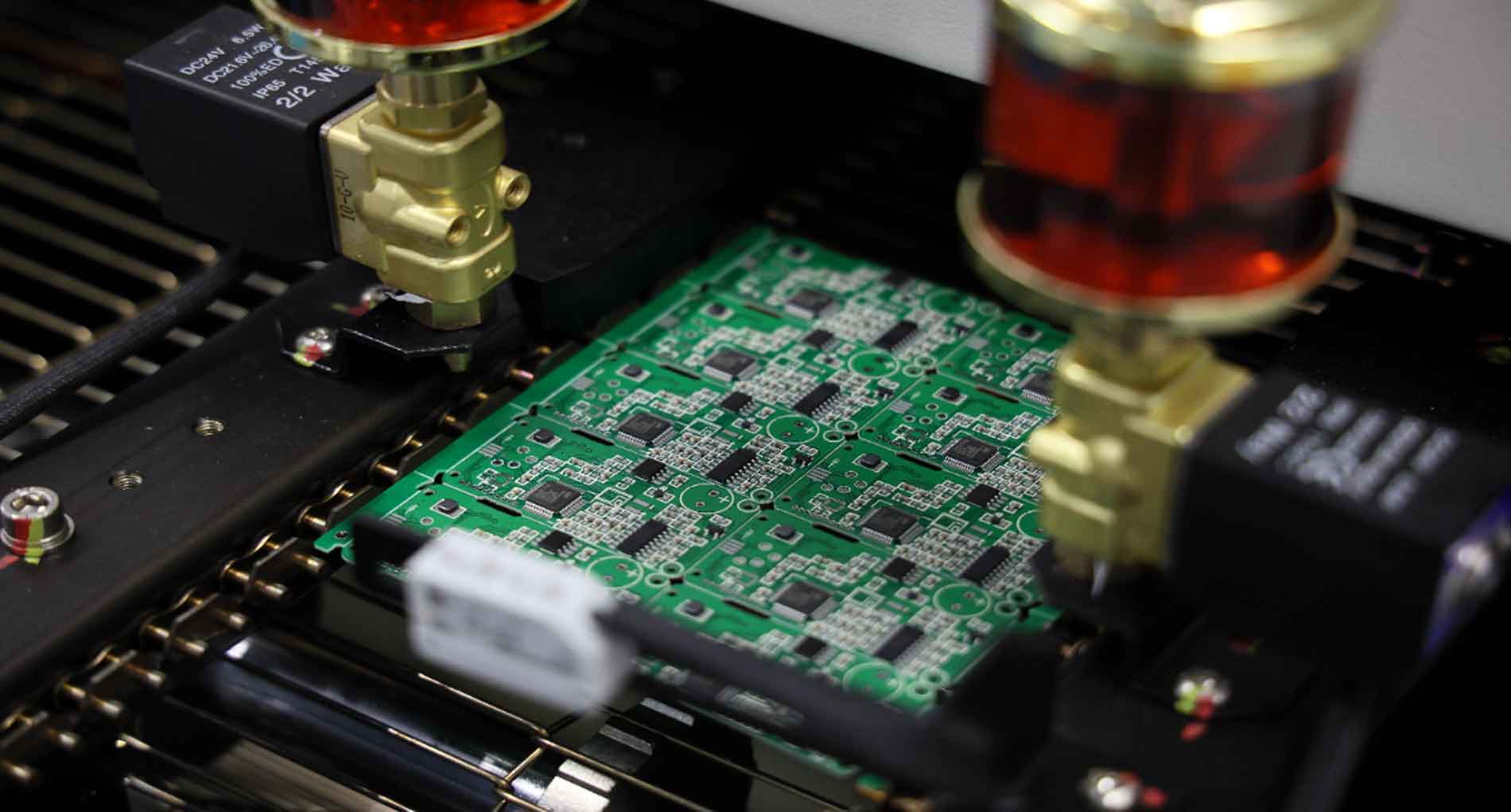

PCB fabrication involves the actual manufacturing of the PCB, including printing the conductive traces and drilling holes for the components. Quality control is essential in PCB fabrication to ensure that the PCB meets the design specifications.

V. Component Placement

Component placement involves placing the electronic components on the PCB. Factors to consider in component placement include the size and orientation of the components.

VI. Soldering

Soldering is the process of bonding the electronic components to the PCB using solder. Quality control is essential in soldering to ensure that the components are correctly bonded to the PCB.

VII. Testing and Inspection

Testing and inspection involve verifying the circuit's functionality and ensuring that the PCB meets the design specifications. Quality control is essential in testing and inspection to ensure that the final product is of the highest standard.

VIII. PCBA Manufacturing Quality Control Techniques

To ensure quality control in PCBA manufacturing, it's essential to have quality control checkpoints at every stage of the process. Common issues in PCBA manufacturing include misaligned components, soldering defects, and circuit shorts.

IX. Conclusion

PCBA manufacturing is a complex and precise process that requires careful attention to detail and adherence to best practices. Quality control is essential to ensure that the final product is of the highest standard. By following the best practices and paying attention to quality control, manufacturers can ensure that their products meet the highest standards of quality and performance.

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: