address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

How Much Is The Price Of Circuit Board Welding And Assembly

How much is the price of circuit board welding and assembly Huiya Technology, high-end positioning, only for high-end circuit board processing

Introducing the updated 2023 (tomorrow/category information)【】

2023 Updated (Tomorrow/Category Information)

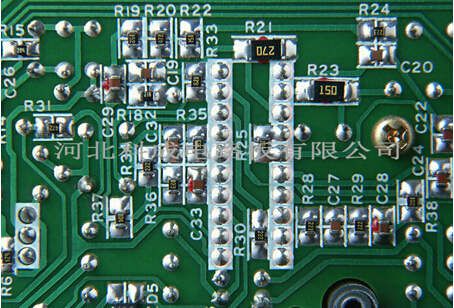

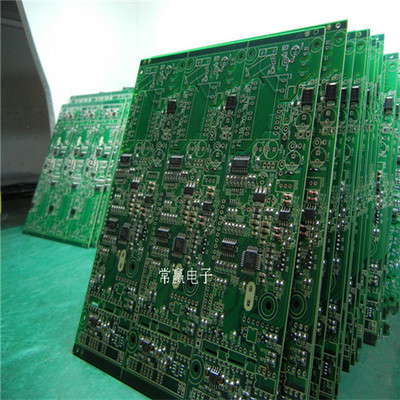

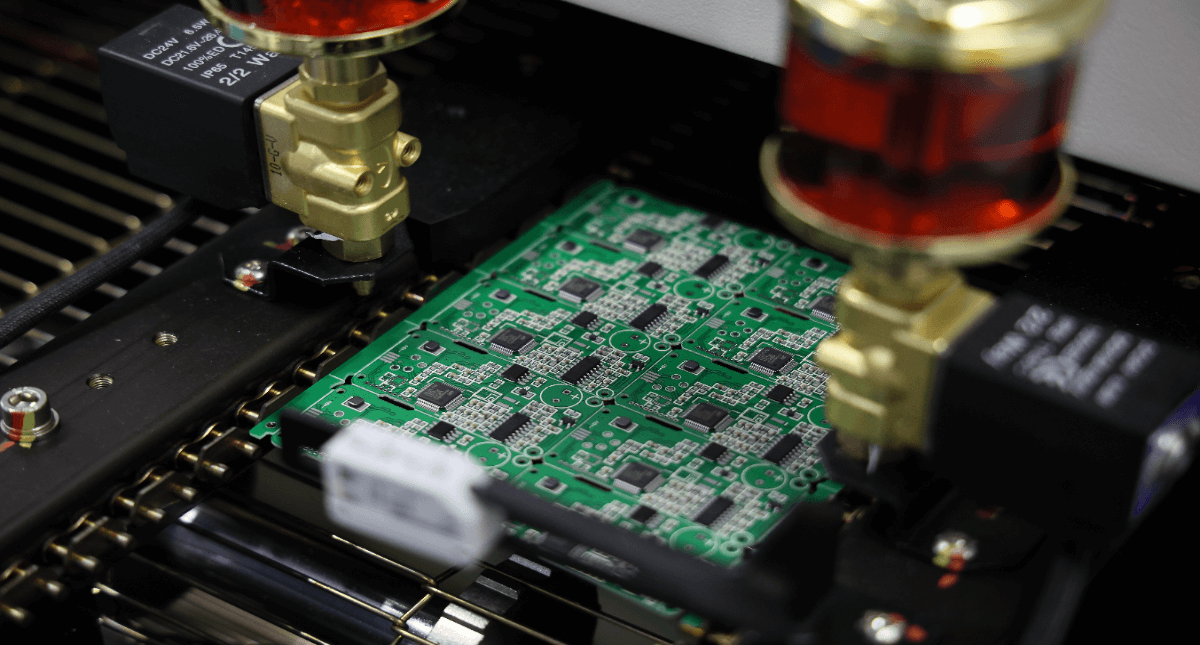

Updated in 2023 (tomorrow/classified information) How much is the price of circuit board spot welding assembly? Huiya Technology, high-end positioning, only for high-end circuit board processing, focusing on 2-68 deep precision PCB development and manufacturing in 14 years!!! Circuit board processing The on-time delivery rate is 95.4%, and the one-time pass-through yield rate is 99.6%. It is good at small and medium-sized batches of multi-layer PCBs , watch singing and proofing! The air-conditioning plant circuit board manufacturing plant has 36 employees. The operators have more than two years of industry experience, and the management and technical personnel have more than six years of industry experience. They have X-RAY, AOI inspection equipment, and Yamaha SMT placement machines. It is one of the intelligent manufacturing enterprises with high quality, high efficiency and strong flexibility in this field.

The copper strip substrate is first cut and split into a size suitable for processing and production. Before the substrate is laminated, it is generally necessary to properly etch the braised copper strip by brushing, micro-etching, etc., and then attach the dry film photoresist to it with an appropriate temperature and pressure. Send the substrate with dry film photoresist into the ultraviolet exposure machine for exposure. The photoresist will form a polymerization reaction after being irradiated by ultraviolet rays in the light-transmitting area of the film, and the circuit image on the film will be transferred back to the dry film photoresist on the surface. . What is needed for high-frequency circuit board processing Huiya Technology attaches great importance to quality and service, and one-stop outsourcing service for circuit board design ...High frequency and high speed, rich experience in circuit board design, good at computer, communication, industrial control, medical treatment, vehicle electronics and many other fields ...After tearing off the protective film on the film surface, fix and remove the non-illuminated area on the film surface with sodium carbonate water and ammonia water, and then use ammonia water to mix ammonia water to corrode and remove the exposed copper strip to form a circuit. Then wash off the dry film photoresist with light sodium oxidized ammonia water.

Lead-free spot welding of circuit boards which is good focuses on PCB manufacturing, circuit board processing for more than 30 years, professionally provides one-stop service from SMT patch, DIP plug-in, testing, assembly, packaging, quality assurance, reasonable price, welcome to call us! High What is needed for high-frequency circuit board processing Huiya Technology attaches great importance to quality and service, one-stop outsourcing service for circuit board design...High frequency and high speed, rich experience in circuit board design, good at computers, communications, industrial control, medical, vehicle electronics and many other fields. ..2023 updated (tomorrow/category information)

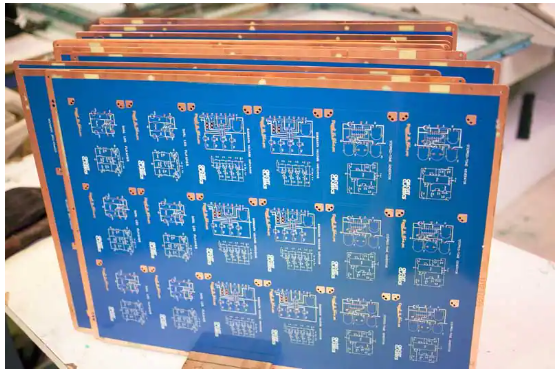

The completed outer layer circuit board must be bonded with glass fiber resin film and inner layer copper tape. Before lamination, the outer layer board needs to be blackened (oxidized) to passivate the copper surface to reduce insulation; and to make the copper surface carbide of the outer layer circuit easy to form good adhesion with the film. When stacking, the outer layer circuit boards with more than six layers of circuits (including ﹞) are riveted in pairs with a strapping machine. Then stack them neatly between the thick mirror plates with a tray, and send them into a vacuum press machine to harden and bond the film with appropriate temperature and pressure. The pressed circuit board uses X-ray manual positioning drill to drill the target hole as the reference hole for the alignment of the inner and outer layers. And the edge of the board is properly cut and cut to facilitate subsequent processing. 2023 Updated (Tomorrow/Category Information)

Cut the circuit board into the shape specification required by the customer with CNC forming machine (or milling machine). When cutting, fix the circuit board on the bed (or grinding tool) through the originally drilled positioning hole with the pin to form it. Cut the wrist of the coalition army and then grind the bevel to facilitate the insertion of the circuit board. For circuit boards formed by multi-pieces, it is often necessary to add X-shaped twisted wires to facilitate customers to separate and disassemble after insertion. Drain off the dust on the circuit board and the ionic pollutants on the surface.

Howyang is a professional PCBA processing manufacturer with its own PCB board factory and SMT patch processing factory . It can provide one-stop PCBA such as PCB design , PCB board manufacturing, component purchasing, SMT patch, DIP plug-in, PCBA testing, and finished product assembly. processing services. Circuit board spot welding assembly telephone Huiya Technology, high-end positioning, only for high-end circuit board processing, 14 years of focus on 2-68 deep precision PCB development and manufacturing!!! The on-time delivery rate of circuit board processing is 95.4%, and the one-time through yield rate 99.6%, good at small and medium batches of multi-layer PCB, table singing and proofing! The circuit board spot welding processing factory specializes in the production of large, medium and small batches of multi-layer circuit boards, 24H shipments, sample delivery rate 99.5%, free expedited service, select on demand , the quantity is cheap, the workers are sufficient, and the delivery is expedited, welcome to consult! Updated in 2023 (tomorrow/classified information)

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: