address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

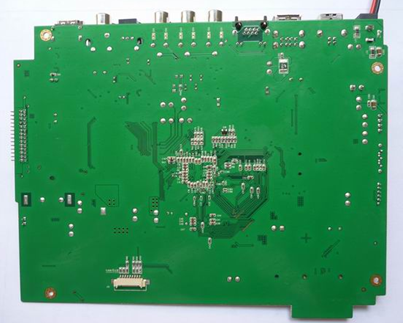

Circuit Board Fabrication and PCB Assembly: From Concept to Creation

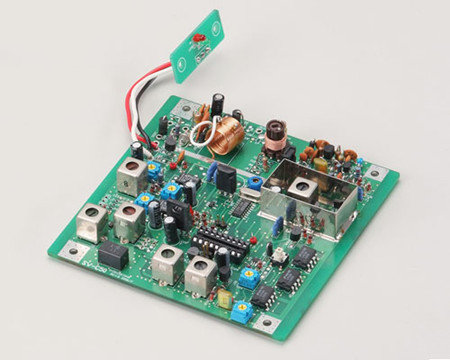

If you’re someone who is interested in electronics, then you must be familiar with circuit boards and PCBs (Printed Circuit Boards). From small DIY projects to complex industrial machinery, circuit boards play an essential role in the functioning of most electronic devices. However, have you ever wondered how these intricate boards are made? The process of circuit board fabrication and PCB assembly involves several stages, from the design concept to the final product. In this blog, we will take you through this process and shed light on the complexity and precision required in creating a successful circuit board. Whether you’re a beginner or an experienced maker, this article will provide you with a comprehensive insight into the world of circuit board fabrication and PCB assembly.

Section 1: Understanding the Design Concept

The first step in circuit board fabrication and PCB assembly is developing a design concept. This concept encompasses the circuit idea and the component placement on the board. Choosing the right software and tools is crucial to start the process of creating a circuit board. A software program such as Eagle PCB is one such popular choice among designers to develop a schematic and a board layout.

Component selection and placement is equally crucial at this stage. It is crucial to choose the right components to achieve optimal circuit performance. The size and placement of components are important to ensure smooth PCB assembly in later stages.

Section 2: Creating the PCB Layout

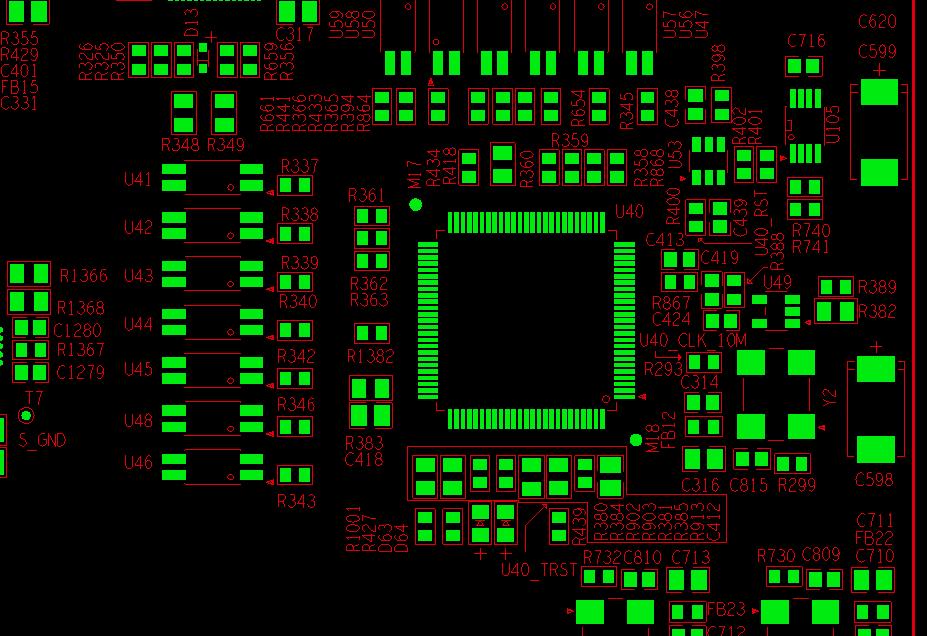

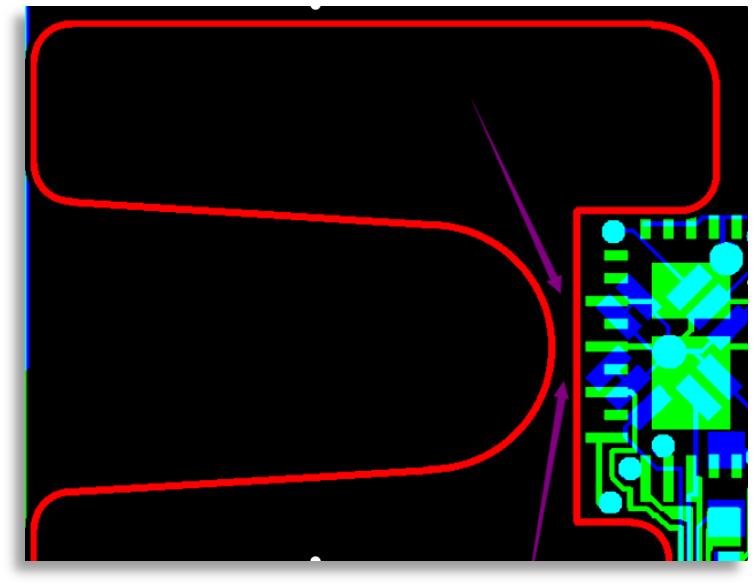

Once the initial design concept is developed, the next step is creating a PCB layout. The layout involves tracing the circuit and designing the physical layout of the board. The optimization of the layout and routing are crucial to keep the circuit board functioning correctly. During this stage, the thickness of the copper traces, layers, drill holes, and spacing are decided.

Tools like DipTrace, Altium Designer, and KiCAD are popular software programs that can be used to create the PCB layout.

Section 3: Manufacturing the Circuit Board

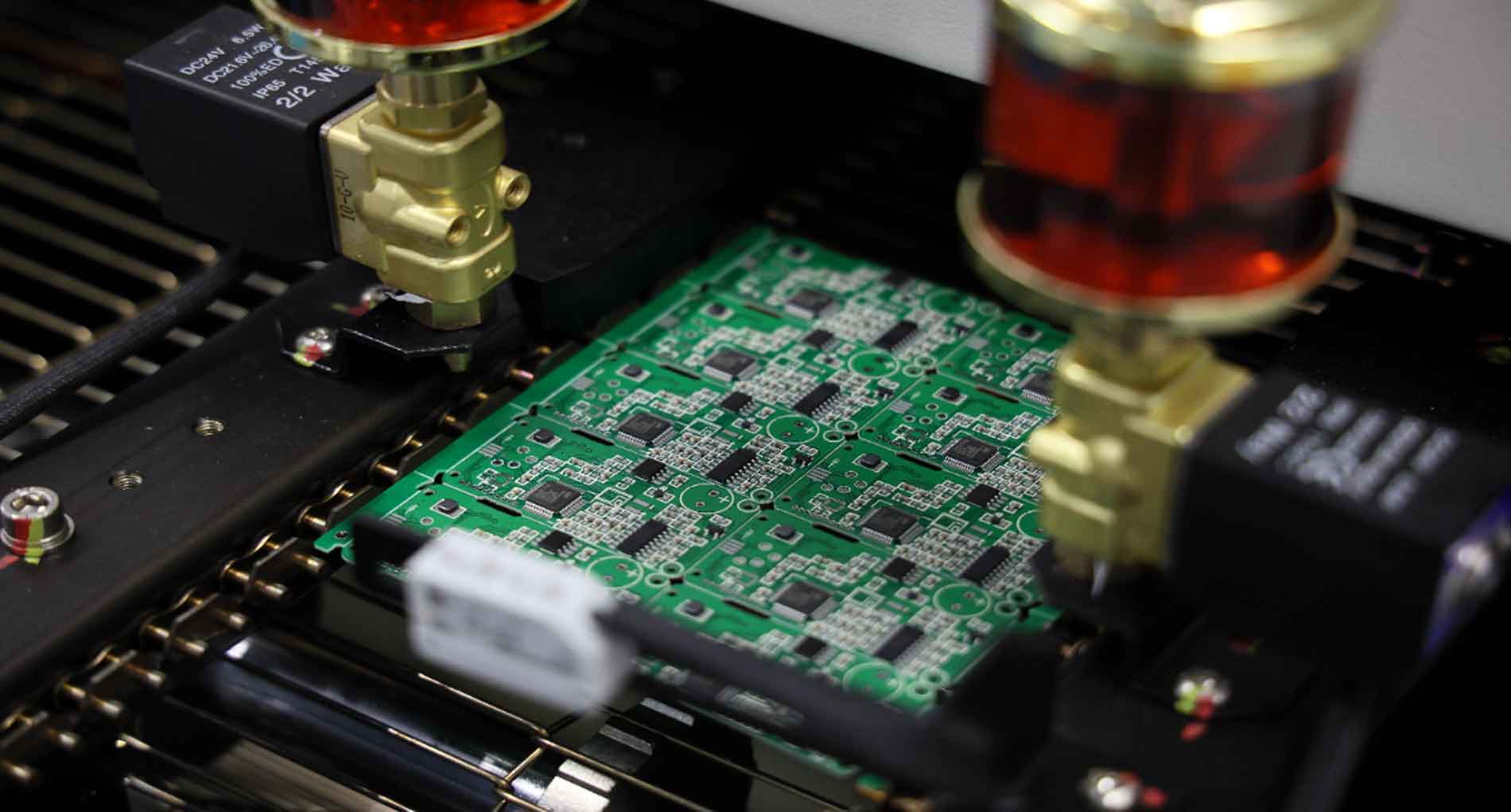

In the manufacturing stage, the board layout is converted into the final product. A stencil is created with Adobe Illustrator, which is used for printing a pattern onto the board with solder paste. The pattern is printed using a machine that applies solder paste to the board. Chemical etching is then used to remove excess copper and metal deposition is used to cover the board with a metal layer.

Section 4: Assembly and Testing

After the creation of circuit boards, the components are placed, and soldered onto the board. The placement of components is the most critical step of the entire process since precision is key to achieving the optimal performance of the circuit board. After the board is assembled, it goes through testing to ensure the proper function of each component. Quality control measures are undertaken to check for the presence of defects, shorts, and other assembly errors.

Section 5: Improving PCB Efficiency

In modern times, surface mount technology has become increasingly popular since it reduces the size of the components. High-density interconnect techniques are also used to achieve a compact, high-performance board. There are different types of PCBs available in the market, each requiring special considerations during the fabrication and assembly stage.

Section 6: Troubleshooting Common Problems

Despite the precision involved in the circuit board fabrication process, errors and defects are sometimes unavoidable. Understanding common errors in PCB fabrication and assembly, finding and fixing errors during and after the fabrication process, and effectively testing and debugging the finished board are all important steps in troubleshooting common problems.

Conclusion

In conclusion, the process of circuit board fabrication and PCB assembly involves various stages from concept to creation. Understanding the intricacies involved in each step is essential to achieving a successful circuit board. The importance of precision and efficiency in electronic devices cannot be overstated. As the complexity and compactness of electronic devices continue to increase, the importance of optimal PCB design and assembly will only grow. We hope this article has given you valuable insights into the world of circuit board fabrication and PCB assembly.

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: