address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

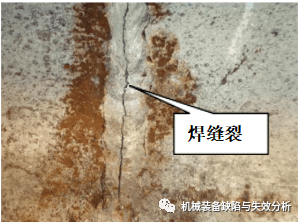

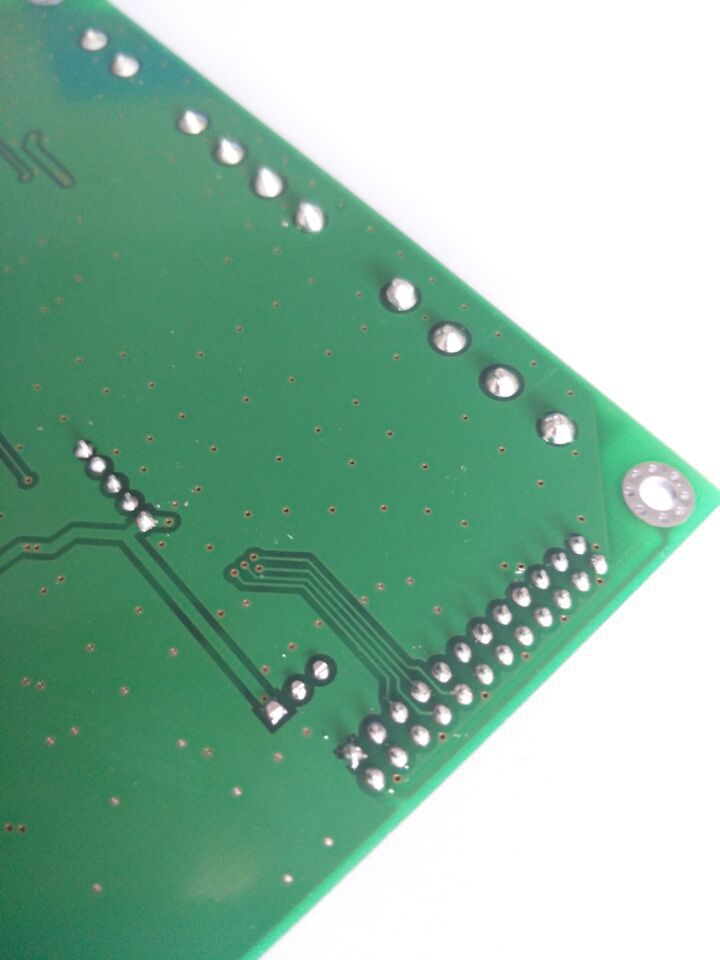

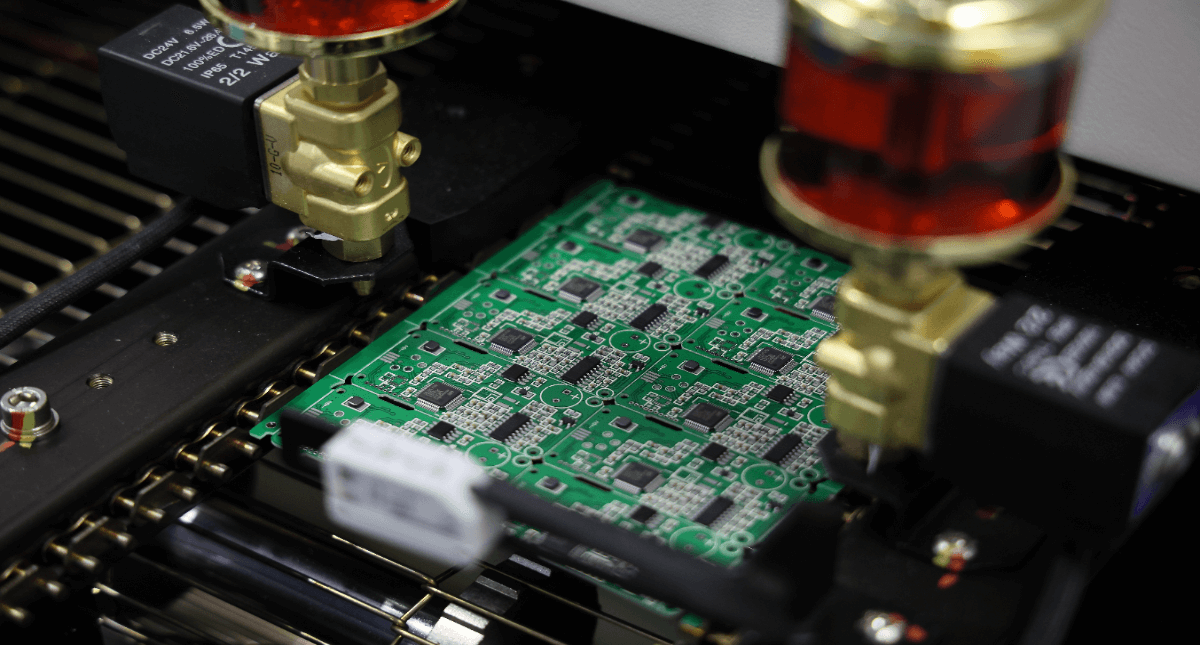

The Reason For Welding Cracks In SMT Processing?

What is the reason for welding cracks in SMT processing? The reason for the cracks in processing

Nowadays, there are more and more electronic products, and they are becoming more and more refined. As long as the products that use electricity need circuit board SMT chip processing and manufacturing , Shenzhen Lingzhuo specializes in providing one-stop service for overall PCBA processing and manufacturing. Next, we will analyze the reasons for welding cracks in SMT chip processing .

Causes of Welding Cracks in SMT Chip Processing

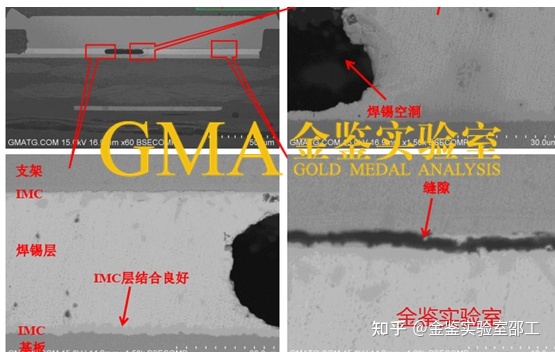

1. The infiltration of PCBA pad and component welding surface does not meet the processing requirements.

2. The use of solder paste does not meet the processing standards.

3. The thermal expansion coefficients of welding and various materials of the electrode level do not match the smt chip manufacturing , and the spot welding is unstable when it condenses.

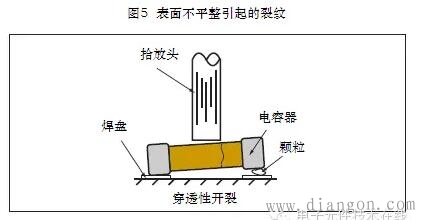

4. The setting of the reflow soldering temperature curve cannot make the organic chemical volatile organic compounds and water in the solder paste evaporate before entering the reflow area.

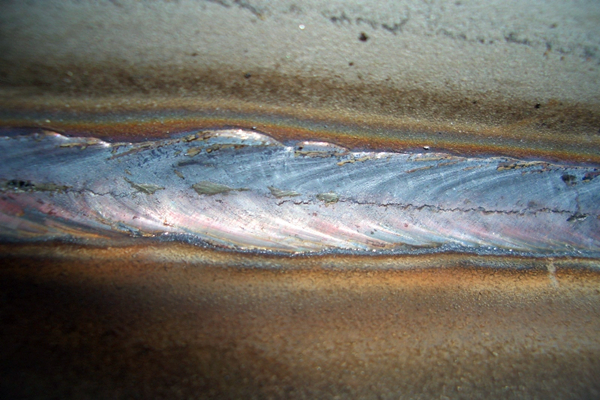

5. The problems of lead-free soldering materials in SMT chip processing are high temperature, high interfacial tension and high viscosity. The increase of interfacial tension will definitely make it more difficult for the gas to escape in the refrigeration process, and the gas will not be easily discharged, which will increase the proportion of cracks. Therefore, there are many vent holes and cracks in lead-free soldering in SMT chip processing.

6. In addition, because lead-free soldering temperature is higher than that of lead-based soldering, especially when the size is large, multi-layer boards, and electronic devices with high thermal conductivity, the maximum temperature is usually around 260 ° C, refrigeration The temperature difference from condensation to room temperature is large, so the stress of lead-free soldering is relatively large.

The above is what is the reason for welding cracks in SMT chip processing? The introduction of the reasons for SMT chip processing cracks, I hope it can help everyone, and if you want to know more about SMT chip processing information, you can pay attention to the update of Lingzhuo proofing.

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: