address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

What Is pcb panelization :guidelines

WHAT IS THE PANEL

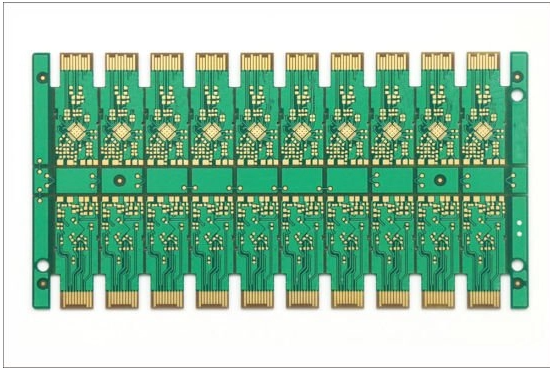

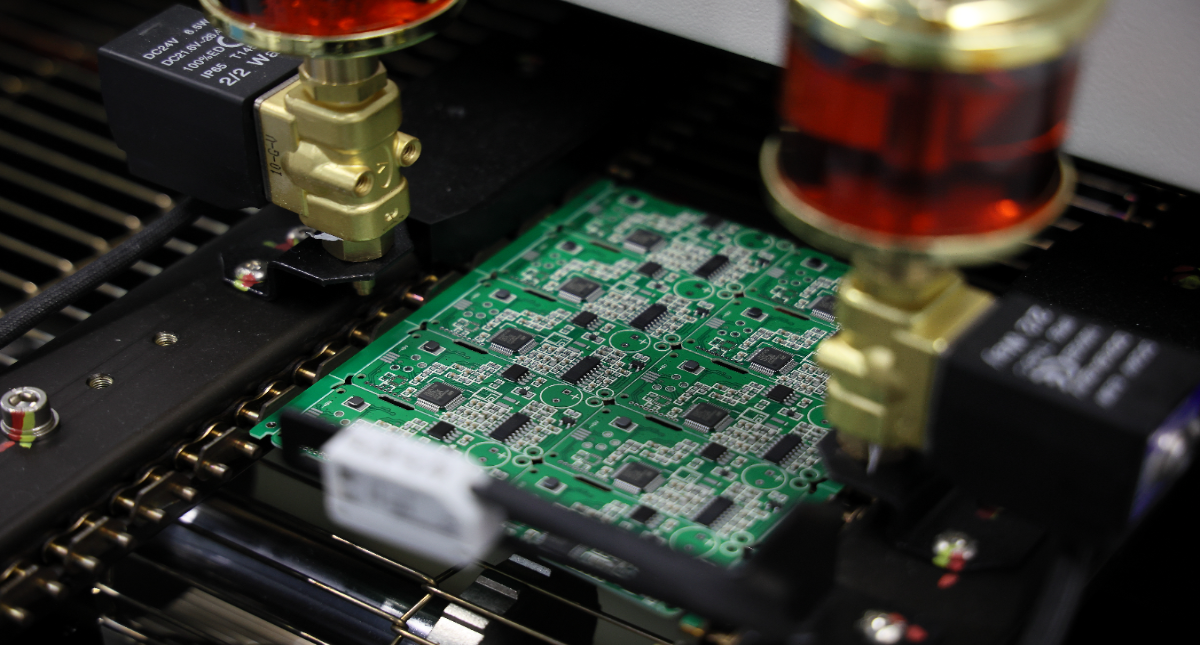

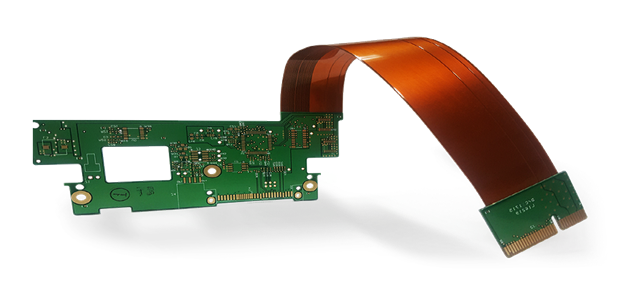

On the concept of panel and paneling, there can sometimes be confusion even among professionals. The assembly panel is the product that the OEM expects to be delivered by the PCB manufacturer, intended to be inserted in the pick & place machines of the assembly lines, as in this example:

The panel is a PCB with an optimized size for assembly because it must be large enough to fit into the machines of the manufacturer's SMT lines. But its characteristics should also take into account the needs of manufacturing, where it can be convenient to work panels containing several printed circuits, even of different types, in order to make the most of the material.

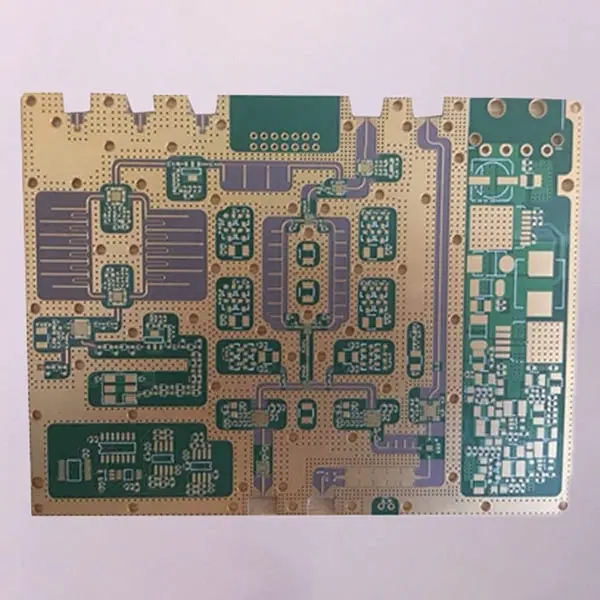

So in reality a panel looks like in the following figure, in which the same PCB design is repeated several times, as many times as it is possible to fit into the dimensions of the panel itself.

Other elements present in the panel are:

the side strips (rails), i.e. the additional areas necessary to reach the necessary dimensions and transport;

the panel fiducial markers, that is the signs affixed to the printout so that the machine recognizes them, to determine the side of the card (top or bottom) and its orientation; the characteristics of the fiducials are defined by the IPC standards

test coupons, to carry out tests on the quality of the lamination;

the centering holes (holes) necessary to facilitate the various processes;

The reference information, in the form of writing or bar code.

THE COST REDUCTION FACTORS IN PCBPANELIZATION

A version of the panel is already made in the prototyping phase, but - we point out - when a PCB, and its panel, are considered acceptable for assembly, it does not mean that it is also optimized for its assembly. manufacture.

In addition, the typical flow of DFM consists of the use by the OEM of the guidelines provided by the assembler, at a later stage than the design stage. At that point, the project is sent to the PCB manufacturer, who configures it through their CAM software, and then sends feedback to the OEM. The latter can only realize at this stage how many panels are needed and therefore the actual production costs.

On the other hand, it would be essential for the OEM to have a software tool capable of including the manufacturer's and assembler's guidelines right from the design stage. In this way, the project can also be optimized for paneling, with obvious economic savings.

For example, it might be convenient to slightly change the shape of the PCB, to make more pieces fit into the panel area. But in general, this allows you to anticipate as much as possible any production problems, where it is the panel and not the single PCB that is processed.

The features necessary to fully optimize the paneling include:

archive of the guidelines of all partners, both for manufacturing and for assembly;

rapid creation of panels optimized for both manufacturing and assembly;

management of factors such as panel measurements, strip dimensions, margins, number of boards per panel, and protrusions;

possibility to add the various typical elements of the panel (fiducials, holes, writings, etc.);

checks of typical problems of the panel, such as the correct positioning of the break-aways on the perimeter of the board (phase of the detachment of the board from the panel);

Calculation of the amount of material used and its cost.

To this list must be added the possibility of carrying out DFM checks relating to the problems of the panel, which cannot emerge if the DFM analysis is carried out only at the board level. The following figures show three examples of production problems related to the paneling.

Currently, the software for Manufacturing Analytics is the most advanced frontier in the digitalization of electronic production and the factor that really makes the difference in terms of competitiveness. But what is Manufacturing Analytics? It is simply "Data Analytics" applied to production. Data Analytics is the process of analyzing data sets that allows you to draw conclusions about the information they contain.

There are four main types of data analysis in PCB panelization:

Descriptive analysis helps answer questions about what happened.

Diagnostic analysis helps answer questions about why things happened.

Predictive analytics helps answer questions about what will happen in the future.

Prescriptive analysis helps answer questions about what should be done

When we talk about Manufacturing Analytics software and therefore how to apply Data Analytics to production, our main goal is productivity. In other words, the question is how we can increase productivity in the production process. In general, productivity can be defined as the ratio of the quantity of production to the weighted average of the inputs used in the production process.

WHY IS MANUFACTURING ANALYTICS SOFTWARE SO USEFUL?

The most important answer to the question of increasing productivity lies in the data generated within the factory. A “digital twin " of operations may be able to analyze and understand what is happening, why it is happening, and how to improve it. Research shows that while the amount of data generated by manufacturing operations increases exponentially, only a small portion of it is actually collected and an even smaller portion is analyzed.

Our goal is to change this state of affairs with a practical approach that focuses on multiple levels of data analysis in manufacturing (Manufacturing Analytics).

THE ADVANTAGES OF MANUFACTURING ANALYTICS

Manufacturing Analytics improves asset management with accurate real-time utilization and overall equipment effectiveness (OEE).

Helps capture and investigate comprehensive material and process traceability data for PCBs and assemblies using high-availability big data storage.

Optimize operation and work by measuring and analyzing how resources are used and monitoring WIP (work-in-progress) in real-time.

It guarantees quality and promotes improvement by identifying and analyzing process defects and material and process failures.

Finally, Manufacturing Analytics increases the efficiency of the transition from design to production, detecting the factors that influence the yield and the areas for improvement.

HOW THE MANUFACTURING ANALYTICS PLATFORM WORKS

Manufacturing Analytics provides added value in 4 different business areas:

Performance and use of equipment

Get a complete overview of business performance for all manufacturing sites, lines, and equipment, including Overall Equipment Effectiveness (OEE), KPI reports, and dashboards.

Compare performance across factories and production lines, and view historical trends.

Calculate planning and quality performance factors.

Quality

Track yield and DPMO at each process inspection or test station.

Instantly trigger notifications with defined upper and lower control limits.

Use in-depth analysis to determine the root cause of quality problems.

Supply chain

Provides material information on inventory, consumable costs, age, and location.

Perform manufacturer returns analysis for engineering feedback.

Traceability of materials

Get full PCB assembly traceability, including materials, box construction, process data, and test results.

It allows you to meet customer requirements by generating automated traceability reports.

Compare quality between material suppliers.

It supports the storage of large databases for the collection of measurement data.

PLATFORM FOR MANUFACTURING ANALYTICS

We have an advanced Manufacturing Analytics platform in our solution portfolio. It is a Big Data platform for the collection, storage, processing, and analysis of production data, which allows you to provide meaningful insights. It is an "Enterprise Solution", which means that it allows you to define basic plant planning, manufacturing, material use, delivery, and shipping, as well as determine inventory levels.

Our platform for Manufacturing Analytics is also an Enterprise Solution because it allows control over multiple sites. If a company has several plants, regardless of their geographic location, it enables a central implementation, which allows for the collection, review, and comparison of data across multiple sites. Real-time data is available everywhere for decision-making.

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: