address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

A Complete Guide to the Manufacturing Process of Multilayer Flexible PCB Assembly

Generally, the flex PCB assembly process is used for various reasons in the modern world and technology. Traditionally, it is used for the replacement of wire controls and settings. The flex Flexible PCB assembly process has been known to evolve since World War II. That has turned to be now increased in fame as days pass by.

The flex PCB assembly process of installation and usage is quite easy and advantageous. It is ideal for simple applications that can adhere to several perfect variations. That is used to solve and tackle any given circuit board task and job.

Hence, with such versatility, most people want to know more about it. Therefore, today we will discuss a complete guide on the flex PCB assembly process.

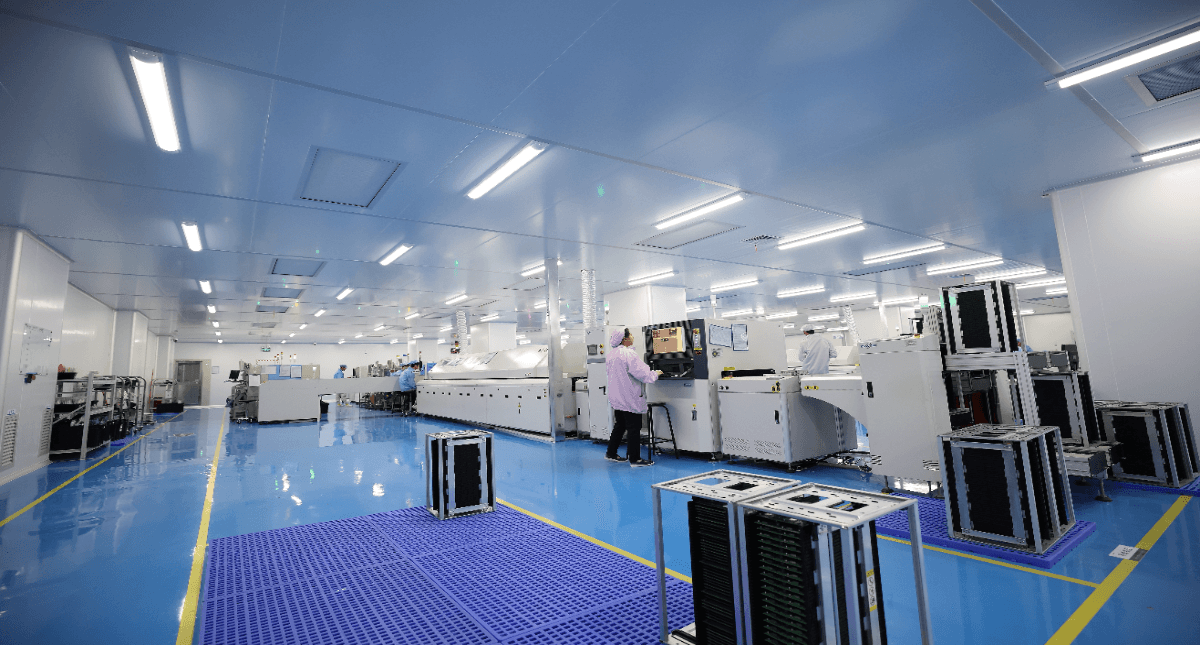

Smt pcb factory

What is meant by flexible printed circuits?

A flexible printed circuit is known to be very lightweight. It is an electrical circuit, and it can be easily used for narrower spaces or that are much crafted. Meanwhile, these are more a merely in which the flex PCB assembly can bend. The flex electrical circuits can allow the presentation of the other differences or advantages.

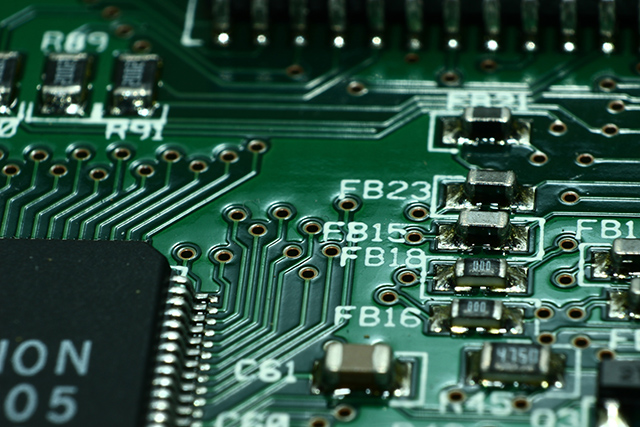

The flex PCB assembly circuit electrical boards do constitute various things. It has a strip of conductive metals that are often made from copper. That is then insulated with the help of a dielectric mask or material.

The board of the circuit falls under as quite functional. Whose main function is to carry out the signals that are coded as electrical. They offer a good and stable mechanic flexing that allows the users to opt for the connectors that are regarded as smaller. These connectors can be a good way to shield the EMI noise that is often radiated.

The PCB is the main element substrate and a non-conductive board. It is used to connect various electronic parts that lead to making a circuit based on electric rules.

What are the types of flex PCB circuits?

There are several types of flex PCB assembly circuits. However, some of the major ones and basic types are mentioned below in further detail.

Single side-flex PCB circuits

The first basic type of flex PCB circuit is the one with a single side. These circuits are known to be single-sided since they only have a single metal layer. This metal layer is present on one side of the layer, referred to as dielectric.

Double side-flex PCB circuits

The other type of flex PCB assembly circuit is the double-sided one. Unlike the single side-flex PCB circuits, this one has a metal layer on both sides. These layers are present on either side of the dielectric layer by nature.

Multi-layered flex PCB circuits

Next are the multi-layered flex PCB circuits. In the double side-flex PCB circuits, the layer of metal is often connected by the help of metalized holes.

Similar holes are also found on this type of flex PCB circuit. They have various copper layers that are not adjoining. Instead, they are separated. Moreover, they are also layered by dielectric metals.

Rigid-flex PCB circuits

The rigid-flex PCB circuit is a type that has elements belonging to the two types. One is hard, and the other is flexible. This combination leads to the formation of another circuit known as a hybrid circuit electrical board.

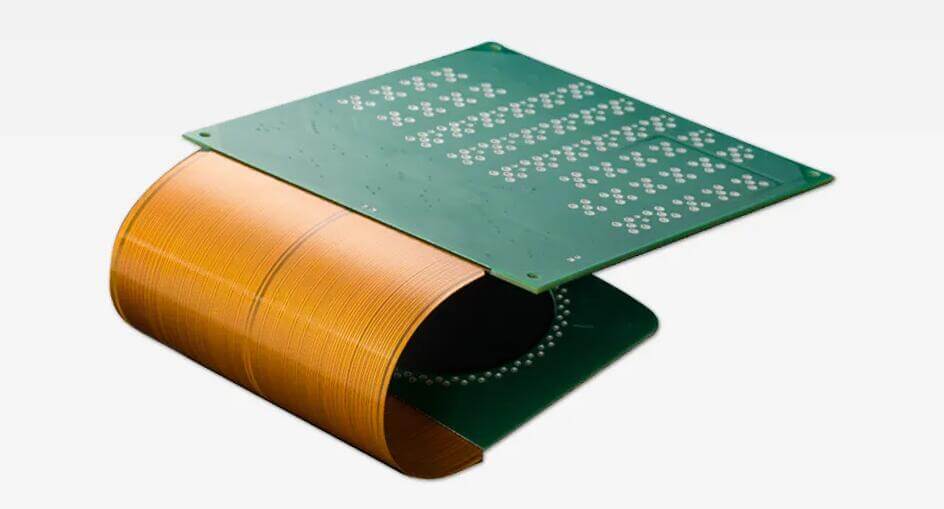

Multilayer Flexible PCB

What are the benefits of the flex PCB assembly process?

If we generally compare the common rigid boards and the cabling system, we can say that flex PCB has many benefits. The advantages include a very accurate wiring system and a mechanical connector. Or is also used to complete the design and offers a high density of circuit.

It is also used to choose a vast range of working temperatures. Or for better quality for the robust signals. It also allows the improvement of controlling the size and other reliable factors.

The production of the automated is useful for eliminating human errors as well. The flex PCB circuits are designed to route only for the ones added or designed in them.

With the use of much labor in the middle of printing the PCB. The flex PCB assembly process is quite affordable from a money and times perspective.

The flex circuit electrical boards are available in customized forms and shapes. It is all possible due to the flexibility of the process of designing, which is not restricted by the presence of double dimensions. The allowance of this flexibility can also be a source of installation and the addition of a third party. This third face is often used to connect the two or more two planes.

The functionality of the flexible circuit electrical boards also proved to improve other various aspects. Like, a better and increased flow of air. The dissipation of heat and the high-density population is done by using a simple geometry of the circuit.

What are the main structural implications of the flex PCB circuits?

Before the circuit is designed, the two main structural implications are used. They are present for the dictation for selecting a conductor. The static application only requires a circuit that is flexible for easy installation. This application only opts for ED, also known as electrodeposited, which is usually copper. This is also a much more adorable option.

Meanwhile, the other one is the dynamic flexing implications. And as the name refers that this one dynamically uses flexing. It happens during the use of the product daily. There are several examples of this type of application. Some of them involve flip cell phones, laptops, personal computers, and much more.

What are the capabilities of the flex printed circuits?

The single and double type of the flex PCB circuits can highlight the reverse bar. It can be done with the help of a hole, finger, and termination known as ZIF. The multi-layered flex PCB circuits can be able to include more than 20 layers and can handle enough of a high-density circuit.

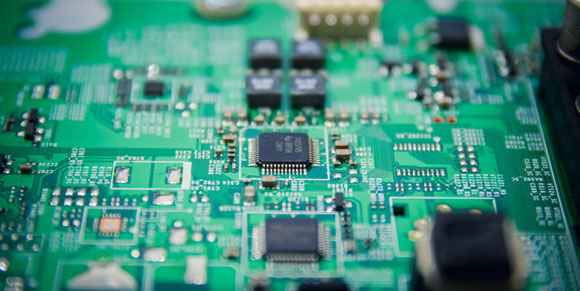

It is all possible with the help of the several layers of conductive metal and resistors that are embedded. Or by the advanced help of the shielding that is known as EMI. The flexible circuit electrical boards can use the smallest area and size of components. That is used for the improvement of the overall integrity, performance, and thermal output of the signal.

The designs that are quite flexible are also used for similar high-density parts. That is often termed rigid-flex PCB circuits. The controlling of the impedance also helps in the improvement of signals to switch quickly. Or helps for the rapid transitions.

The transmission of the signals in every flex PCB circuit needs to have a uniform material for the thickness, and the signals are regarded as electrical. The added protective services are also available from the films that can lower noise. Also, they help in the reduction of the lines of signals. Meanwhile, the components known as stiffeners implement a more flexible circuit.

What are the materials for the flex PCB assembly process?

The flex PCB circuit boards consist of identical materials to the other PCBs. All the circuits tend to relate similarly and require a metal conductor. That can conduct electricity.

While copper is used as the most common material. Copper often comes in diverse types of thicknesses. That is needed for several other reasons. The other list of conductors includes silver ink, aluminum, carbon, and Constantan.

The layer of the flex printed circuits is glued together with the help of any adhesive. The specific use of the material is mainly dependent on the need of the consumer. Or on the thickness of the conductor. However, every bond must remain quite strong while being in the temperature range that is currently operating.

The overall flex PCB assembly process gets a final touch at the end of the process. That is often done by the recommendation of the consumer and can be customized as well. Hence, if any additional changes are required, then they can be done without any problem.

What are some advanced features of the flex PCB assembly process?

Some of the modern features of the flex PCB assembly process are that it includes the use of graphic and crimp tools. It has heaters that are flexible with various added possibilities of all kinds. Hence, you can find a flex PCB circuit electrical board as per your needs and requirements. Therefore, it is true that for every need, a flex PCB board is available.

You should know the basics and get the use of PCB in a good way. You can use its features in a good way when you know complete details about it.

Final Remarks:

There are many things that people want to find out about the flex PCB assembly process and its benefits. Hence, to know more about it, refer to the mentioned details. It includes everything about the flex PCB assembly process that can be ideal for those who have a slight idea about it.

Finally, for any inquiries, questions, or comments, feel free to contact us. We’ll get back to you as soon as we can.

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: