address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

LGA: A Flexible and Reliable PCB (Printed Circuit Board) Surface Mounting Packaging Technology

When building a computer, you need to fit a processor into its socket. As you go through different CPU types, you will most certainly come across the terms LGA, PGA, and BGA. The three are surface-mount packaging technologies but with a few differences.

Intel processors primarily use LGA (Land Grid Array), but newer AMD processors are slowly adopting the topology. Therefore, it is vital to understand what Pin Grid Array is about to use it correctly. We have looked at the technology in detail, plus how it compares to PGA and BGA. Let's dive in!

What is a Land Grid Array(LGA)?

Why Use LGA Surface Mounting Technology?

List of Microprocessor LGA Sockets

Installing CPU on LGA Socket Motherboard

LGA vs. PGA: Which is Better?

LGA vs. BGA: Which Surface Mounting Technology Should You Use?

Summary

What is a Land Grid Array(LGA)?

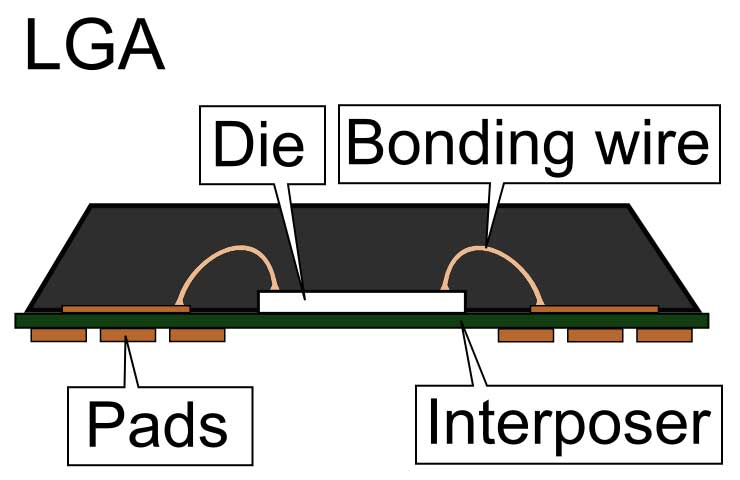

Pin Grid Array is a flexible and reliable technology used for surface-mount packaging used for soldering modules to integrated circuits. The most notable feature in LGAs when using a socket is having pins on the socket instead of the IC. But you can connect the LGA chip and PCB electrically via a socket or direct soldering.

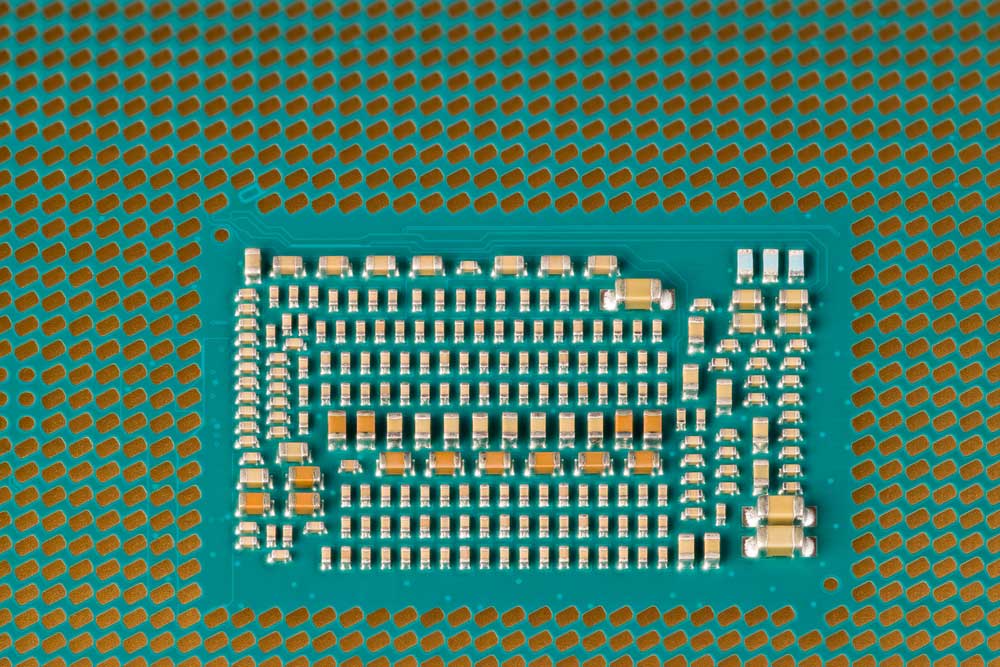

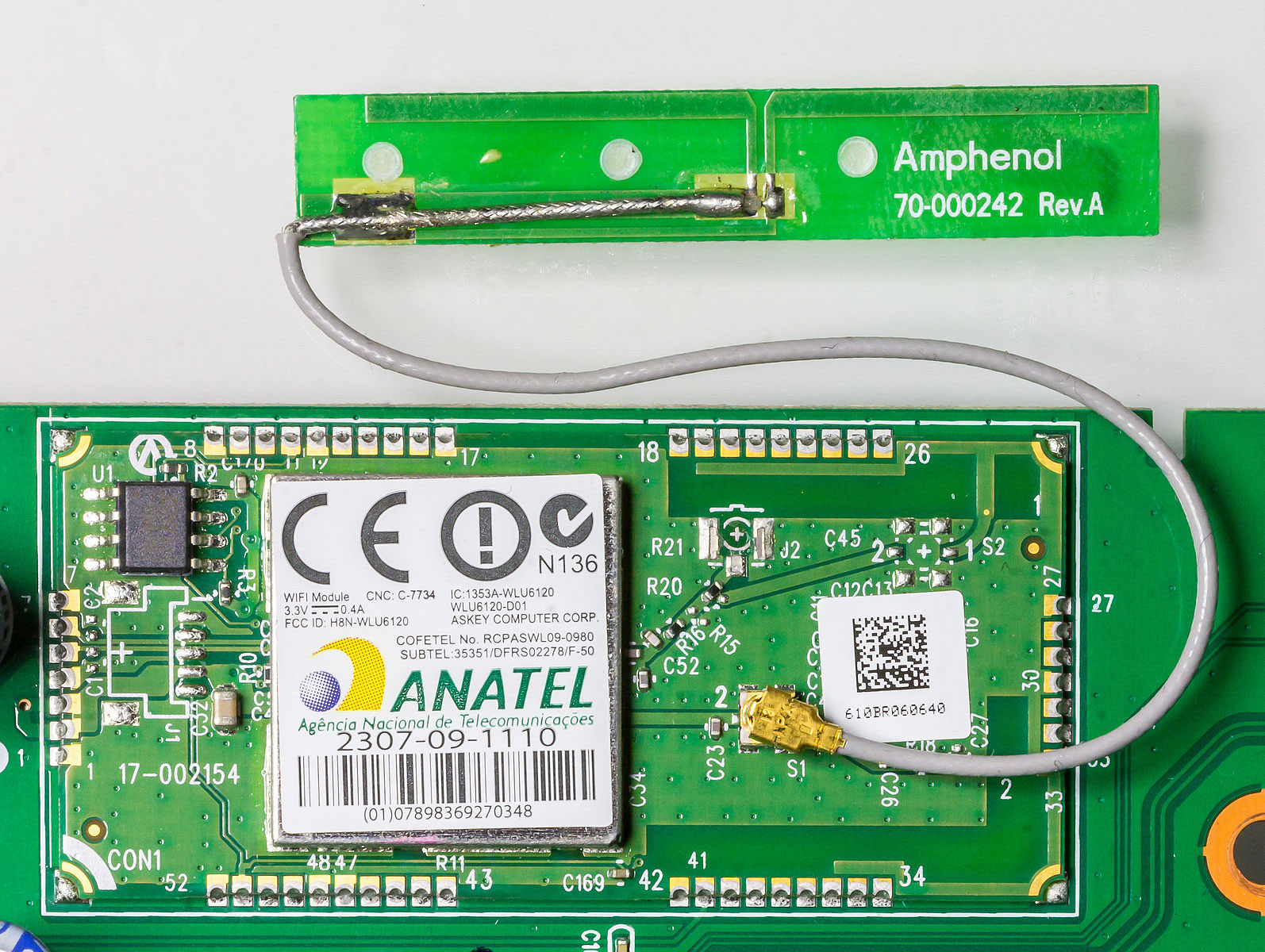

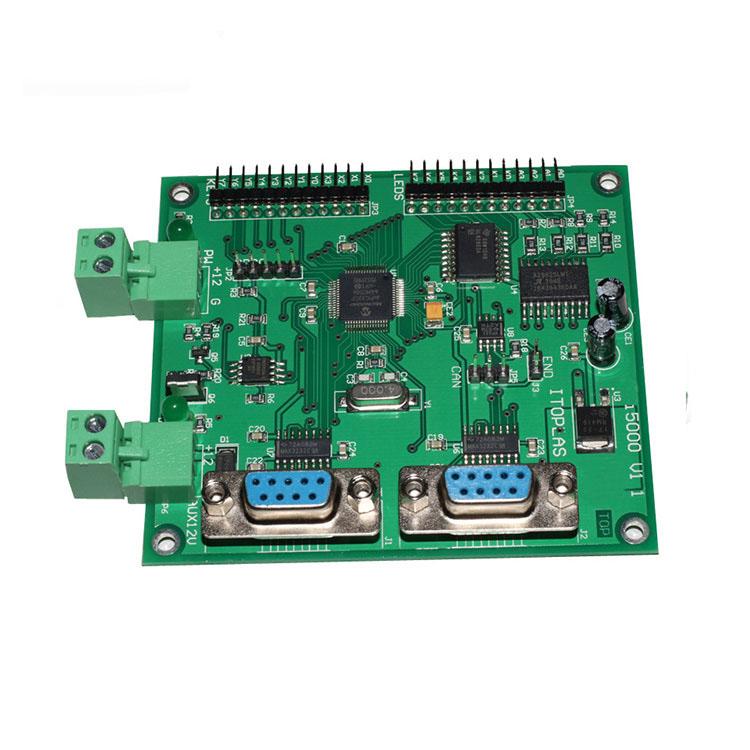

A modern microprocessor with LGA packaging

Why Use LGA Surface Mounting Technology?

The technology is relatively new (introduced in 2010) but has since become the industry's gold standard due to the following benefits.

Improved Conductivity

The nickel-gold surface finishing prevents corrosion during soldering and storage. Therefore, the technology improves conductivity and enables the connected modules to perform optimally.

Footprint Optimization with Geometric Pad Layout

Negative warpage can occur during reflow soldering. But the unique geometric pad layout in middle and near-corner pads eliminates this problem.

Minimal Impact on Antenna Path

With ground pads under the RF components, LGA technology has little impact on the antenna path.

LGA ground pads

Source: Wikimedia Commons

Customizable Overprinting

The level pitch and pad size enable customizable overprinting to optimize performance and enhance the yield rate.

List of Microprocessor LGA Sockets

Both Intel and AMD processors use Pin Grid Array sockets. Therefore, we will split them into their respective categories.

Intel

Socket B (LGA 1336)

Socket T (LGA 775)

Socket J (LGA 771)

Socket R (LGA 2011)

Socket B2 (LGA 1356)

Socket H (LGA 1156)

Socket H2 (LGA 1155)

AMD

Socket G34 (LGA 1974)

Socket F (LGA 1207)

Socket C32 (LGA 1207) - socket F replacement

Installing CPU on LGA Socket Motherboard

LGA surface-mount packaging technology places contact pins on the motherboard socket, not on the processor chip. This design requires the following three installation steps.

Step 1: Open the motherboard bracket using its metal lever.

Step 2: Align the bracket with the processor chip precisely with a max error of 2mm. The maximum drop and height should be 4mm.

Step 3: Use the lever to close the bracket and lock it securely.

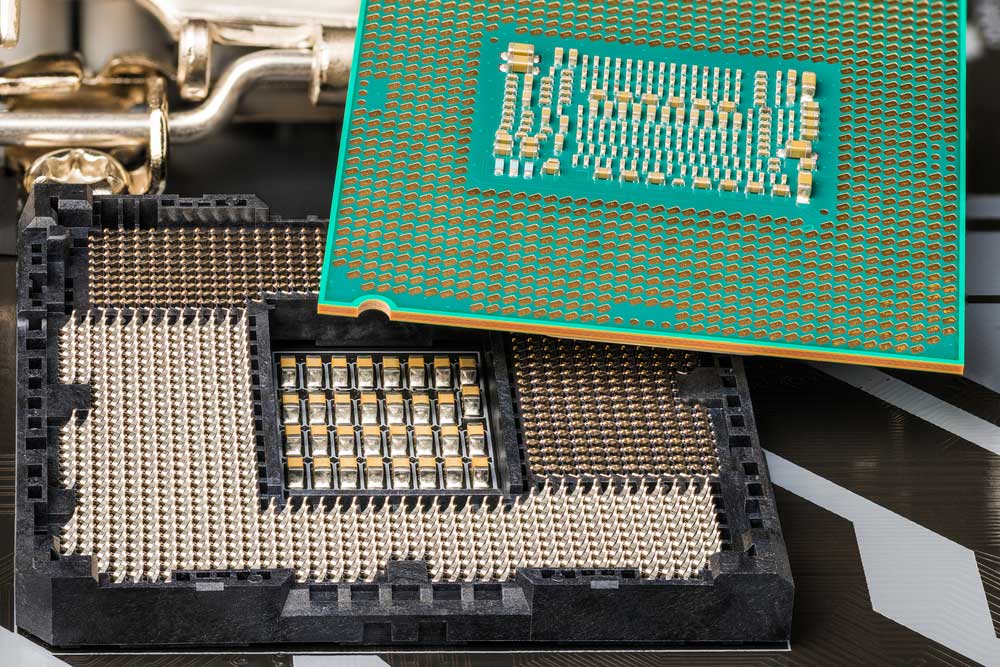

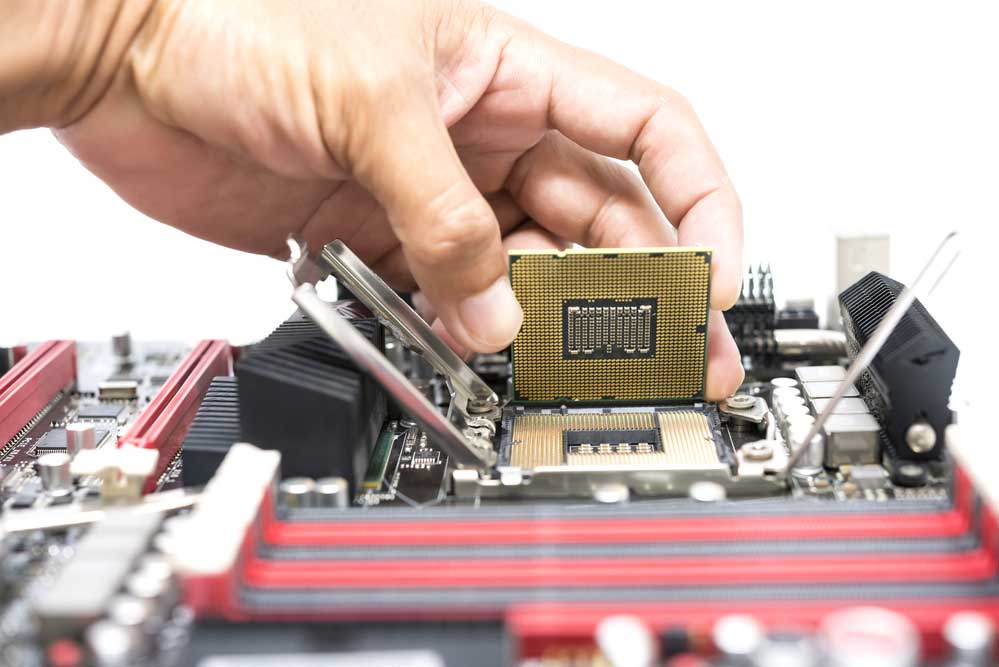

A microprocessor with Pin Grid Array packaging and an LGA socket on a motherboard. Note the locking metal lever.

It is as simple as that. If you want to remove it from the CPU socket, first release the locking latch. After that, lift the chip from the middle using your thumb and index finger.

LGA vs. PGA: Which is Better?

LGA and PGA (Pin Grid Array) are closely related because one is the direct opposite of the other. With LGA, the contact pins pop out from the circuit board while the IC or chip has flat pads. Therefore, the PCB is more prone to damage because the pins can break.

But with Pin Grid Array, the IC contains the pins while the motherboard socket has holes to accommodate the pins. With that in mind, we can compare two in five categories.

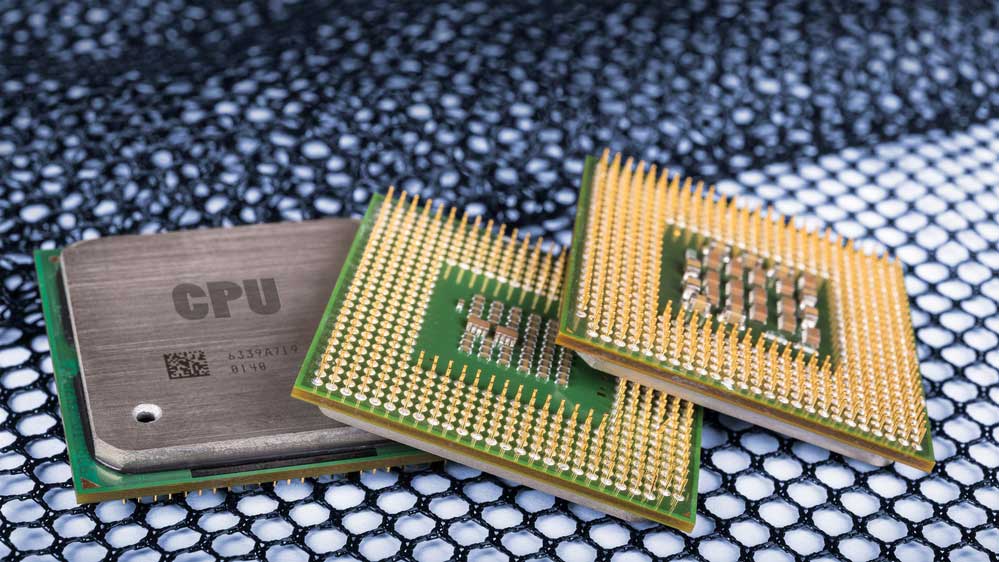

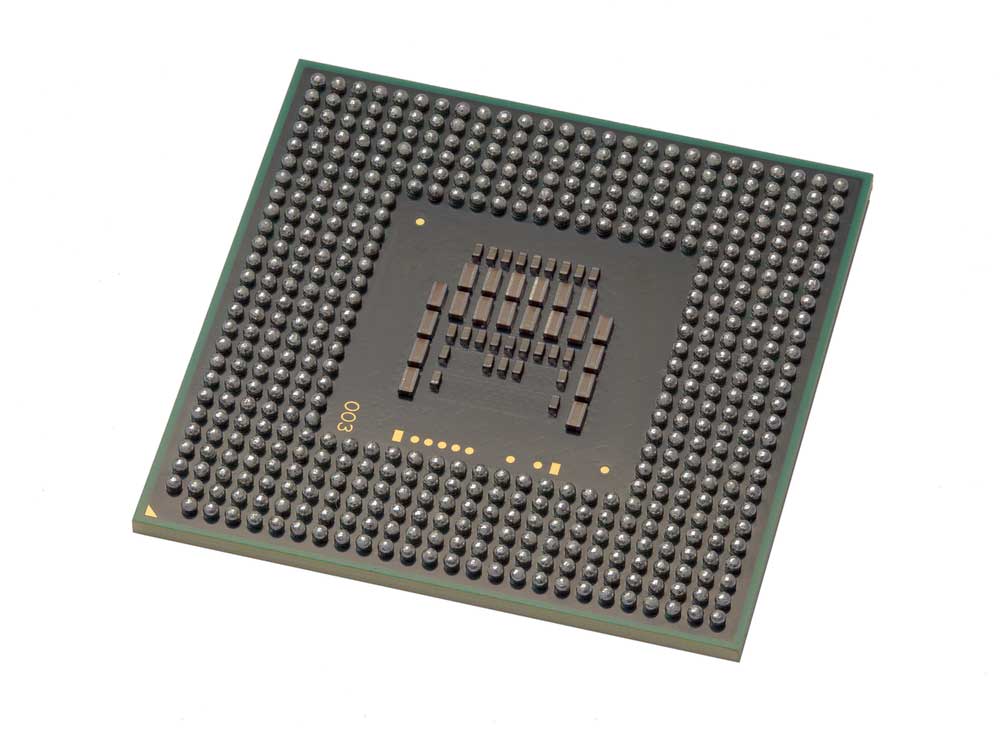

A computer processor with PGA packaging

Durability: LGA technology offers a more durable CPU and less durable motherboard. But the PGA layout creates a more durable motherboard and a less durable CPU.

Build quality: LGA sockets are more fragile than PGA sockets because you cannot damage the holes easily. But you can easily bend LGA socket pins if you apply pressure without proper alignment.

Space efficiency: Pin Grid Array pins are smaller than their Pin Grid Array counterparts, so more can fit in the same space.

Compatibility: Pin Grid Array sockets are more common in Intel processors, but newer AMD chips are adopting the technology. But, PGA has been the primary topology in AMD processors and is more compatible with these chips.

Installation: Both require extreme care to avoid bending the pins. But PGA installation is easier because the pins slide into holes instead of connecting to a flat surface.

A processor with PGA packaging being installed

A processor with LGA packaging being installed

LGA vs. BGA: Which Surface Mounting Technology Should You Use?

LGA and BGA (Ball Grid Array) are also related technologies because both offer the following:

Automatic soldering

Automatic pick and place capability

Easy handling

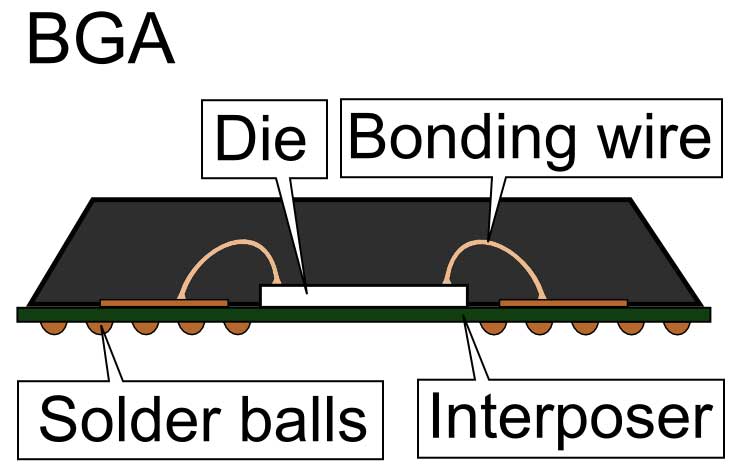

However, they are also very different because BGA technology has balls as the contact points between the PCBs and ICs. On the other hand, LGA technology has no balls in non-socket technologies. Instead, it has flat copper contacts that get soldered directly to the PCB (or sit on the socket pins).

A computer processor with BGA packaging

The LGA configuration improves cost efficiencies and flexibility, making it ideal for mass production and smart manufacturing. Therefore, you should consider using Pin Grid Array because it beats BGA in the following areas.

Durability

BGA ball height can vary by up to 50%, and this affects functionality & coplanarity. Therefore, you must apply heat to attach the solder balls to the module. Further heating is necessary to fix the solder balls to the module's ground when manufacturing the modules.

However, the unique Pin Grid Array layout optimizes heat dissipation and connections. This design minimizes PCB warpage during reflow soldering and affects soldering joints in the middle and near corners. Also, the nickel-gold finish on the copper pads enhances durability by preventing corrosion.

Flexibility

With BGA, you must apply heat to attach the solder balls to the module. Also, you must apply the solder paste with precision to attach the balls of solder fixed on the module. Since the previously-fixed solder has a specific temperature profile, it limits the range of soldering pastes the customer can use.

But with Pin Grid Array, you engineer the blank nickel-gold pads on the module's surface. These blank pads offer high flexibility for customer-specific soldering paste selection. This flexibility is vital because customers should select solder paste based on their needs and processes.

BGA package side view

Source: Wikimedia Commons.

Reliability

Residues of flux on module ball surfaces lead to passivation by creating a layer above the conductive surface. This layer affects conductivity, reducing the module's yield rate and impeding performance.

However, the optimized pad size in LGAs enables customizable overprinting as per customer needs to provide an excellent yield rate. The pad layout also minimizes impact on the RF path (ground pads are under the RF components), while the flat design optimizes customer use cases.

Summary

In summary, Pin Grid Array is the most preferred interface for microprocessors due to the benefits described above. If you need ICs with an LGA topology for your project or have any questions/comments about the article, leave a message, and we'll get in touch asap.

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: