address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

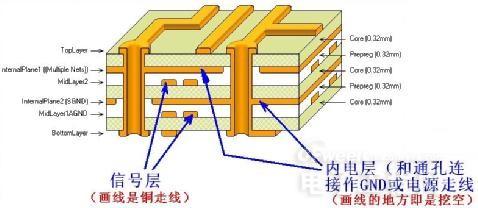

Wiring Precautions for Multilayer Circuit Boards

ICT testing machine 1. The scope and characteristics of ICT Online testing and inspection scope

Promise and keep promise "Yujia Technology" [Yujia Technology] content:

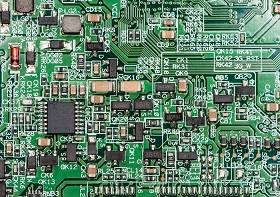

It mainly checks the open circuit and short circuit of individual components on-line and each circuit network. It has the advantages of simple operation, fast and accurate fault location, etc. Figure 4-2 ICT testing machine 1. Scope and characteristics of ICT The scope of online testing and inspection is the electrical performance of online components on the manufactured board and the connection of the circuit network. Not only can quantitatively measure resistance, capacitance, inductance, crystal oscillator and other components, but also can test functions such as diodes, triodes, optocouplers, relays, operational amplifiers, transformers, power modules, etc. , Class, exchange and other IC for functional testing.

--

Components can check out the failure or damage of component values, out-of-tolerance, program errors, etc., and find defects in manufacturing processes and defective components by directly testing the electrical performance of online devices. For the process category, faults such as solder short circuit, wrong component insertion, reverse insertion, missing installation, lifted pins, virtual soldering, PCB short circuit, and disconnection can be found.

--

Fault maintenance does not require much knowledge, and the faults tested are directly located on the specific component pins and network points, and the fault location is accurate. 2. Significance ICT-tested faulty boards can greatly improve production efficiency and reduce maintenance costs because of accurate fault location and easy maintenance. Online testing is usually a mid-production testing process, which can promptly reflect the manufacturing status of small batch circuit board processing , and is conducive to process improvement and promotion.

--

The pcb circuit board is oxidized, which will cause the pcb solder layer to become black and not bright. If there is air oxidation, you can use a rubber to remove the oxidized layer to make it bright and reappear. The PCB board is damp and can be put in Carry out air-drying treatment in the drying box, if the PCB circuit board has oil stains and sweat marks, etc., it should be cleaned with industrial alcohol at this time.

--

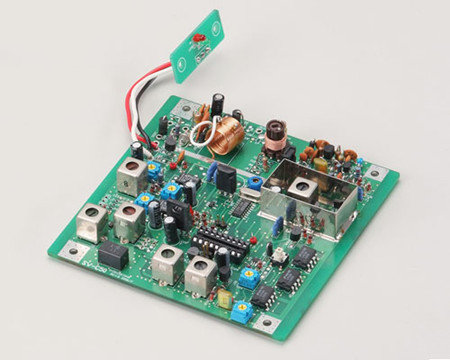

In the OEM production of pcb circuit boards produced by smt chip processing and production, photoelectric pcb factories generally have strict safety operating procedures for chip processing and production processes, which require chip processing workers in the smt technology production workshop of pcb factories to follow This method is used to carry out patch processing, and these rules are analyzed based on problems at each detail level.

--

1. The pcb circuit board must be prepared before welding before welding, so that the solder layer of the electronic device and pcb circuit board is in a solderable state.

2. In the case of SMT chip processing and electric welding, the SMT operator must wear an anti-static cap and pull up all the long hair to be tightly covered by the static induction cap.

3. The pcb board manufacturer carries out the patch processing of the pcb board on the smt production line. During welding, the soldering iron tip is not allowed to be immersed in the flux for a long time, and other highly corrosive chemicals cannot be used as the flux.

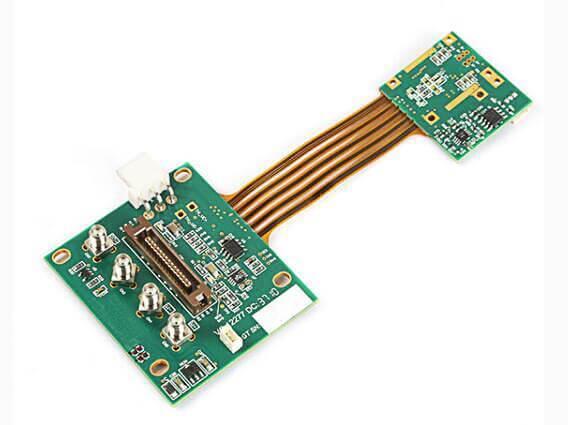

Soldering paste is a muddy body made of aluminum alloy welding raw material powder and thick flux evenly stirred. It is an indispensable soldering material in the production and processing of SMT chips. It is widely used in small Board processing , the solder paste has a certain viscosity at room temperature, which can initially stick the electronic components in the established position. Under the welding temperature, with the volatilization of the organic solution and some additives, the electronic components to be soldered will be interconnected with the PCB. together to create a connection.

--

SMT glue, also known as SMT follow-up agent, SMT red glue, is usually red (also light yellow or milky white) mud-like, evenly spread throughout the bonding of ground hardener, paint color paste, organic solution, etc. It is mainly used to fix electronic components on the pcb circuit board. Generally, it is distributed by a fully automatic dispensing machine or a reinforced mesh printing and packaging method. After pasting the electronic components, put it into a dryer or a reflow oven to heat up hardening.

--

Flux is the medium of tin powder, and its composition is basically the same as that of practical flux. In order to better improve the expected effect of printing and packaging, it is sometimes necessary to add a small amount of organic solution, according to the role of surfactant in flux , can destroy the surface of the raw material to be welded and the hydroxide of the tin powder itself, so that the welding material can quickly diffuse and adhere to the surface of the metal material to be welded. The composition of the flux plays a critical role in the spreading, wetting, slumping, viscosity change, clearness and shelf life of the solder paste.

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: